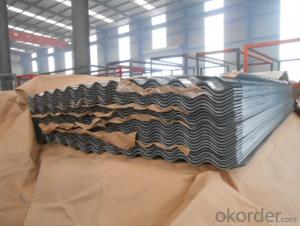

Corrugated Hot -Dip Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Hot Dipped Galvanized Steel Sheet

Description:

The corrugated sheet is a high strength and durable steel, mostly used for a architectural decoration. We have scores of corrugated sheets production lines of different types, producing profiled sheets of all kinds of types and colors. Since it adopts high strength steel sheet and the dimension is designed reasonably, the corrugated sheets are widely used on roofs and walls of various buildings, which can be easily installed, be flexible and changeable, unrestricted by no factor of the buildings.

Corrugated steel sheet is the colored steel plate which has been wave formed with the cold rolling treatment, trough especial coated dispose, the color coated steel panel’s guaranty is 12-15 years.

Application:

It has been widely applied on civil construction like storerooms, special building roof and walls of wide-span steel structure building and so on.

With excellent cold bending molded manufacturability, good decoration effect, strong anti-corrosion ability, are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

Product Specification:

Thickness tolerance: (+/-0.01mm)

Zinc coating: 50-180g/m2

Standard:jis g 3302, sgch

Package: 2- 3 ton/pallet

Specs: 0.14-0.8mm x 900mm x 2000mm

Width:700-1250mm( 750mm,900mm,1215mm,1250mm,1000mm the most common)

Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel ,sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. Could you produce the sheets according to our design?

Yes, we can.

- Q: What are the different profile options available for steel sheets?

- There are several different profile options available for steel sheets, each serving different purposes and offering unique benefits. Some of the most common profile options include: 1. Plain Sheet: This is the simplest and most basic profile option, with a flat surface and no additional features. It is commonly used for general purposes where aesthetics are not a priority. 2. Corrugated Sheet: Corrugated steel sheets have a series of parallel ridges and grooves, creating a wavy pattern. This profile provides extra strength and rigidity, making it ideal for roofing, cladding, and fencing applications. The ridges also enhance water shedding, preventing water accumulation on the surface. 3. Ribbed Sheet: Ribbed steel sheets have a series of raised parallel ridges or ribs running along the length of the sheet. This profile offers improved strength and load-bearing capacity, making it suitable for applications that require structural integrity, such as mezzanine floors, decking, and industrial flooring. 4. Perforated Sheet: Perforated steel sheets have a pattern of holes punched into them, allowing for ventilation, light transmission, and drainage. This profile is commonly used in architectural designs, façades, acoustics, and filtration systems. 5. Tread Plate: Tread plates have a raised pattern of lines or diamonds embossed on the surface. This profile provides extra grip and slip resistance, making it ideal for industrial flooring, stairs, ramps, and walkways. 6. Expanded Metal: Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in a pattern of diamond-shaped openings. This profile offers excellent ventilation, visibility, and security, making it suitable for applications such as grilles, screens, fences, and enclosures. 7. Lipped Sheet: Lipped steel sheets have an edge or lip bent at a 90-degree angle along one or more sides. This profile provides added strength and stiffness, making it commonly used for framing, shelving, and edge protection. These are just a few examples of the different profile options available for steel sheets. The choice of profile depends on the specific requirements of the application, such as strength, durability, aesthetics, and functionality.

- Q: How do steel sheets handle static electricity?

- Steel sheets are generally excellent conductors of electricity, including static electricity. Due to their high electrical conductivity, steel sheets are capable of quickly dissipating any static charge that may build up on their surfaces. This ability to handle static electricity effectively is primarily attributed to the presence of free electrons within the steel's atomic structure. When a static charge is applied to a steel sheet, the free electrons readily move and redistribute themselves, neutralizing the charge and preventing any buildup or discharge of static electricity. Additionally, steel sheets are often coated with a thin layer of protective material, such as zinc or paint, which further enhances their ability to dissipate static charges. Overall, steel sheets are known for their reliable performance in handling static electricity and are commonly used in various industrial applications where electrostatic discharge can potentially cause damage or safety hazards.

- Q: Can steel sheets be used in architectural applications?

- Yes, steel sheets can be used in architectural applications. Steel sheets are often used in architectural projects for their durability, strength, and versatility. They can be used in various applications such as roofing, cladding, facades, flooring, and structural elements. Steel sheets offer a wide range of design options and can be customized to meet specific architectural requirements. Additionally, their corrosion resistance and fire resistance properties make them suitable for long-lasting and safe architectural solutions.

- Q: Can the steel sheets be bent without cracking?

- Steel sheets have the capability to be bent without cracking. This capability relies on several factors including the type and grade of steel, the thickness of the sheet, and the bending process employed. As a general rule, steel sheets can be bent without cracking as long as the bending radius and angle fall within the recommended limits specific to the type and grade of steel being used. Furthermore, preheating the steel sheet before bending can further mitigate the risk of cracking. It is crucial to adhere to proper bending techniques and utilize suitable tools to guarantee successful bending of steel sheets without any cracks.

- Q: Can steel sheets be used in HVAC systems?

- HVAC systems can indeed utilize steel sheets. Due to its robustness, endurance, and resistance to rust, steel is a frequently employed material in HVAC systems. For the construction of ductwork, a crucial component of HVAC systems, steel sheets are frequently employed. The purpose of the ductwork is to distribute conditioned air throughout a building, ensuring that appropriate ventilation and temperature control are maintained. Steel sheets are the ideal choice for duct fabrication since they can endure the typical high pressure and temperature conditions encountered in HVAC systems. Furthermore, steel sheets can be effortlessly shaped and connected together, enabling the customization and installation of ductwork in various dimensions and forms. In conclusion, steel sheets are an appropriate material selection for HVAC systems, as they offer dependable performance and long life.

- Q: Can steel sheets be used for clamps or fasteners?

- Yes, steel sheets can be used for clamps or fasteners. Steel sheets can be fabricated into various shapes and sizes, making them suitable for creating clamps or fasteners that provide secure and sturdy connections.

- Q: Are steel sheets suitable for magnetic shielding?

- Yes, steel sheets are suitable for magnetic shielding. Steel is a ferromagnetic material with high permeability, meaning it can effectively redirect and absorb magnetic fields. This makes steel sheets an excellent choice for shielding against magnetic interference and reducing magnetic fields in various applications.

- Q: Can steel sheets be used for balcony railings?

- Yes, steel sheets can be used for balcony railings. Steel is a strong and durable material that can provide stability and security to balcony railings.

- Q: How do steel sheets handle water resistance?

- Steel sheets handle water resistance very well due to their inherent properties. Steel is a non-porous material, meaning it does not absorb water. Additionally, steel sheets are often coated with protective layers, such as galvanized or stainless steel finishes, which provide an extra barrier against water penetration. This makes steel sheets highly resistant to corrosion, rust, and water damage, making them suitable for various applications, including roofing, construction, and marine environments.

- Q: Can steel sheets be used for cladding or facade systems?

- Yes, steel sheets can be used for cladding or facade systems. Steel sheets offer durability, strength, and a sleek appearance, making them suitable for various architectural applications including cladding or facade systems. They can be customized in terms of color, finish, and shape, allowing for versatile design possibilities. Additionally, steel sheets provide weather and fire resistance, making them a reliable choice for exterior applications.

Send your message to us

Corrugated Hot -Dip Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords