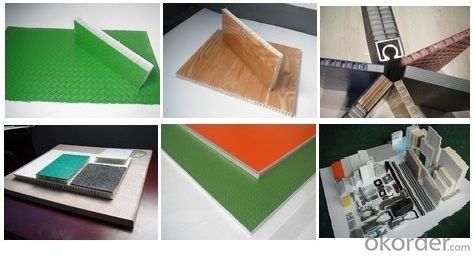

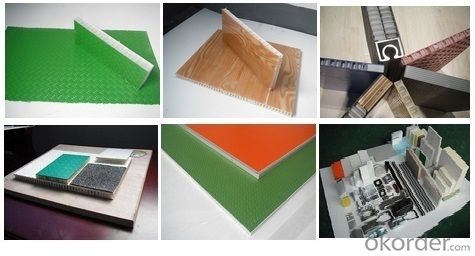

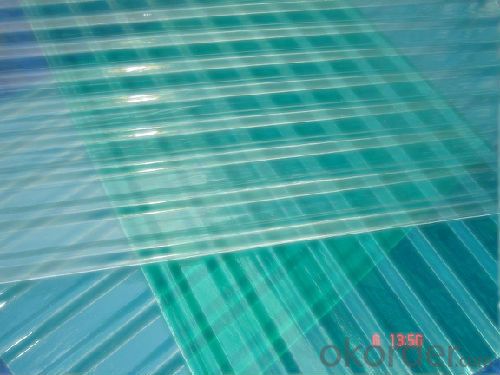

Corrugated FRP Fiber Reinforce Plastic Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

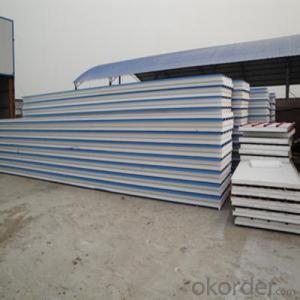

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Corrosion resistance

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

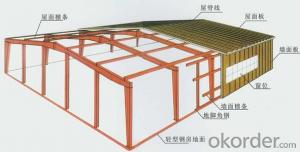

2. Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

3. Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

4. Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

5. Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

6.Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

Specification:

Sandwich including PU、XPS、Polywood and PP Honeycomb ect.

Item | Unit | Parameter |

Thickness | mm | 5mm ~200mm |

Width | mm | <3000mm |

Length | m | <15m |

Heat transfer coefficient | Kol/m2 | 0.57 ~ 0.117(T50-100mm) |

- Q: Can FRP roofing panels be installed on wooden structures?

- Yes, FRP roofing panels can be installed on wooden structures. FRP panels are lightweight and can be easily installed on wooden roofs using appropriate fasteners and sealants to ensure a secure and watertight installation. However, it is important to ensure that the wooden structure is strong enough to support the weight of the FRP panels and that proper insulation and ventilation measures are taken to prevent any potential issues such as condensation.

- Q: Are FRP roofing panels resistant to cracking from temperature fluctuations?

- FRP roofing panels are known for their resistance to cracking caused by temperature fluctuations. These panels are designed to be long-lasting and have exceptional thermal stability, enabling them to endure drastic temperature changes without cracking or warping. The inclusion of fiberglass reinforcement in the material enhances its strength and flexibility, greatly increasing its resistance to thermal stress. Nevertheless, it is worth mentioning that the extent of resistance to cracking may differ depending on the quality and thickness of the FRP panel. Moreover, ensuring the durability and effectiveness of FRP roofing panels necessitates proper installation and maintenance.

- Q: Can FRP roofing panels be used for both new construction and roof replacements?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both new construction and roof replacements. FRP panels are versatile and can be installed on various types of structures, including residential, commercial, and industrial buildings. They are lightweight, durable, and have excellent weather resistance, making them suitable for both new roofs and replacing old or damaged roofs. Additionally, FRP panels are easy to install and require minimal maintenance, making them a cost-effective option for any construction or replacement project.

- Q: Are FRP roofing panels suitable for barns or agricultural buildings?

- Yes, FRP roofing panels are suitable for barns or agricultural buildings. These panels are durable, lightweight, and resistant to weathering, making them ideal for protecting the structure from various elements such as rain, snow, and UV rays. Additionally, FRP panels are often chosen for their excellent insulation properties, which can help maintain a comfortable and regulated temperature inside the barn or agricultural building.

- Q: Are FRP roofing panels resistant to fading?

- Yes, FRP roofing panels are resistant to fading.

- Q: Are FRP roofing panels resistant to lightning strikes?

- FRP roofing panels, also known as fiberglass reinforced plastic panels, are not inherently resistant to lightning strikes. However, they are considered to be safer compared to other roofing materials such as metal or asphalt. The reason for this is that FRP roofing panels are non-conductive, meaning they do not conduct electricity. As a result, if lightning were to strike a structure with FRP roofing panels, the panels themselves would not attract or conduct the electrical charge of the lightning bolt. However, it is important to note that lightning can still pose a risk to any structure, regardless of the roofing material. Lightning seeks the path of least resistance to the ground, and it can travel through any conductive material, such as metal pipes or wiring, that may be present in the building. To mitigate the risk of lightning strikes, it is advisable to install a lightning protection system. This system typically includes lightning rods or air terminals installed on the highest points of the structure, as well as conductive cables that run down the building and into the ground. These components help to safely direct the electrical charge of a lightning strike away from the structure and into the ground. In summary, while FRP roofing panels are not resistant to lightning strikes, they are considered safer than some other roofing materials due to their non-conductive nature. However, it is essential to implement proper lightning protection measures to ensure the safety of any structure, regardless of the roofing material used.

- Q: Are FRP roofing panels resistant to graffiti removal chemicals?

- FRP roofing panels are typically resistant to graffiti removal chemicals. These panels are made from a reinforced plastic material that is designed to be durable and resistant to various environmental factors, including chemicals. However, it is important to note that the level of resistance may vary depending on the specific brand and quality of the FRP roofing panels. It is advisable to consult the manufacturer's guidelines or contact a professional for specific information on the resistance of the panels to graffiti removal chemicals. Additionally, it is always recommended to test the chemicals on a small, inconspicuous area of the panel before applying it to the entire surface to ensure compatibility and avoid any potential damage.

- Q: Can FRP roofing panels be used for pergolas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for pergolas. FRP panels are durable, lightweight, and resistant to corrosion, making them an excellent choice for outdoor structures like pergolas. They provide protection from the elements while allowing natural light to filter through, creating a comfortable and inviting outdoor space. Additionally, FRP panels are easy to install and maintain, making them a practical choice for pergolas.

- Q: Can FRP roofing panels be used for patio covers?

- Yes, FRP roofing panels can be used for patio covers. FRP (Fiberglass Reinforced Plastic) panels are durable, lightweight, and provide excellent protection against the elements. They are often used in roofing applications, including patio covers, due to their strength, resistance to corrosion, and ability to withstand harsh weather conditions.

- Q: Can FRP roofing panels be used for both residential and commercial noise barriers?

- Yes, FRP roofing panels can be used for both residential and commercial noise barriers. Their sturdy and durable construction, along with their ability to reduce sound transmission, makes them an ideal choice for creating effective noise barriers in both residential and commercial settings.

Send your message to us

Corrugated FRP Fiber Reinforce Plastic Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords