FRP Roofing Panel - Custom Design Corrugated Plastic Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

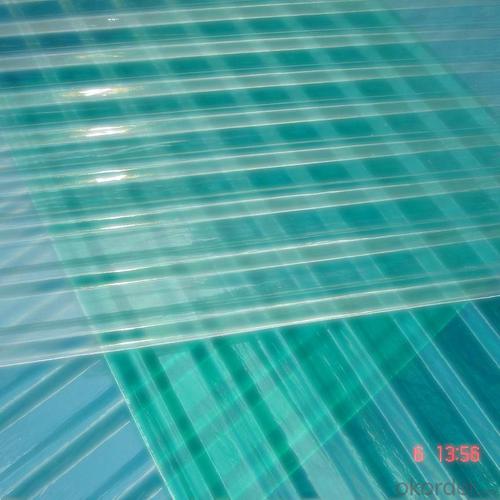

PICTURES

- Q: Can FRP roofing panels be used for modular housing or prefabricated structures?

- Absolutely, modular housing or prefabricated structures can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess exceptional attributes such as being lightweight, long-lasting, and possessing remarkable resistance against corrosion and weathering. Consequently, they are an ideal option for applications of this nature. Installing these panels is a breeze, and they also offer commendable thermal insulation properties. Furthermore, FRP roofing panels come in a variety of designs and colors, which allows for customization and enhances the aesthetic appeal of modular housing or prefabricated structures. Ultimately, FRP roofing panels offer a cost-effective and efficient solution for roofing in these types of structures.

- Q: Can FRP roofing panels be used for universities?

- Yes, FRP roofing panels can be used for universities. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to corrosion, making them suitable for various applications, including universities. They provide excellent weather protection, low maintenance requirements, and can be customized to fit different architectural styles. Additionally, FRP panels can offer energy efficiency benefits by reducing heat transfer, enhancing insulation, and allowing the integration of natural lighting.

- Q: Can FRP roofing panels be used for skylights?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for skylights. FRP panels are lightweight, durable, and provide excellent light transmission, making them a popular choice for skylight applications. They are designed to be weather-resistant, UV-stable, and can withstand extreme temperatures, making them suitable for outdoor use. Additionally, FRP panels are available in various colors and profiles, allowing for customization and aesthetic integration with the surrounding roofing system. However, it is important to ensure that the FRP panels used for skylights are specifically designed and certified for this purpose, as they may have additional features such as enhanced impact resistance or light diffusion properties to optimize their performance as skylights.

- Q: Can FRP roofing panels be used for commercial kitchens?

- Commercial kitchens can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are renowned for their robustness, strength, and ability to withstand moisture, chemicals, and temperature fluctuations. Consequently, they prove to be an ideal option for commercial kitchens, which often experience high levels of humidity, grease, and exposure to various chemicals and cleaning agents. In terms of installation and maintenance, FRP roofing panels are lightweight yet sturdy, making them effortless to install and upkeep. Furthermore, they possess fire-resistant properties, a vital feature for kitchen environments where the risk of fire is elevated due to the presence of cooking equipment. Additionally, cleaning FRP panels is a breeze due to their non-porous surface, preventing the accumulation of dirt, grease, and bacteria. Moreover, FRP panels offer a wide range of colors and finishes, allowing for customization to match the aesthetic of the commercial kitchen. They can also be installed in different configurations, such as skylights or translucent panels, to introduce natural light while maintaining privacy. All in all, FRP roofing panels provide a practical and reliable solution for commercial kitchens. They offer durability and hygiene, meeting the specific requirements of this demanding environment.

- Q: Can FRP roofing panels be used for canopies or entrance covers?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for canopies or entrance covers. FRP panels are lightweight, strong, and durable, making them suitable for various applications including canopies and entrance covers. They provide excellent weather resistance and can withstand harsh environmental conditions such as UV radiation, extreme temperatures, and moisture. FRP panels are also customizable, allowing them to be fabricated in different shapes, sizes, and colors to suit specific design requirements. Additionally, FRP panels have good light transmission properties, allowing natural light to filter through while providing protection from the elements. Overall, FRP roofing panels are a versatile and practical choice for canopies and entrance covers due to their durability, weather resistance, and aesthetic appeal.

- Q: Can FRP roofing panels be used for storage facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for storage facilities. FRP roofing panels are known for their durability, strength, and resistance to various weather conditions, making them ideal for protecting goods and materials stored in a storage facility. They provide excellent water resistance, preventing leaks and water damage to the stored items. Additionally, FRP roofing panels are lightweight, making them easy to install and maintain. They also have a long lifespan, reducing the need for frequent replacements. Overall, FRP roofing panels are a cost-effective and reliable option for storage facilities.

- Q: Are FRP roofing panels resistant to fading?

- FRP roofing panels are known for their resistance to fading. The incorporation of top-notch pigments and UV inhibitors during production safeguards the panels against harmful sunlight. These additives effectively prevent any color fading, ensuring the panels maintain their original appearance for a considerable amount of time. Nonetheless, it is worth mentioning that no material is entirely impervious to the impact of UV radiation, so some minimal fading may occur if exposed to intense sunlight for extended periods. Nevertheless, FRP roofing panels are engineered to endure outdoor conditions and offer long-lasting color retention.

- Q: Do FRP roofing panels have any specific fire rating certifications?

- Yes, FRP roofing panels can have specific fire rating certifications. These certifications are typically obtained by undergoing rigorous testing and evaluation to ensure the panels meet specific fire safety standards.

- Q: Can FRP roofing panels be used for commercial kitchens?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for commercial kitchens. FRP panels are known for their durability, strength, and resistance to moisture, chemicals, and temperature fluctuations. These qualities make them an excellent choice for commercial kitchens, where there is often a high level of humidity, grease, and exposure to various chemicals and cleaning agents. FRP roofing panels are lightweight yet sturdy, making them easy to install and maintain. They are also fire-resistant, which is crucial in a kitchen environment where the risk of fire is higher due to the presence of cooking equipment. Additionally, FRP panels are easy to clean, as they have a non-porous surface that prevents the buildup of dirt, grease, and bacteria. Furthermore, FRP panels come in a variety of colors and finishes, allowing for customization to match the aesthetics of the commercial kitchen. They can also be installed in different configurations, such as skylights or translucent panels, to provide natural light while maintaining privacy. Overall, FRP roofing panels are a practical and reliable choice for commercial kitchens, providing a durable and hygienic solution that meets the specific requirements of this demanding environment.

- Q: Can FRP roofing panels be used in areas with frequent hailstorms?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in areas with frequent hailstorms. FRP panels are known for their durability and impact resistance, making them a suitable choice for regions prone to hailstorms. These panels are designed to withstand harsh weather conditions, including hailstorms, due to their strong and flexible composition. The fiberglass reinforcement in FRP roofing panels provides added strength and resilience, allowing them to endure hail impacts without significant damage. Additionally, FRP panels are lightweight, easy to install, and require minimal maintenance, making them a practical option for areas with frequent hailstorms. However, it is important to choose FRP panels with the appropriate thickness and quality to ensure maximum hail resistance.

Send your message to us

FRP Roofing Panel - Custom Design Corrugated Plastic Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords