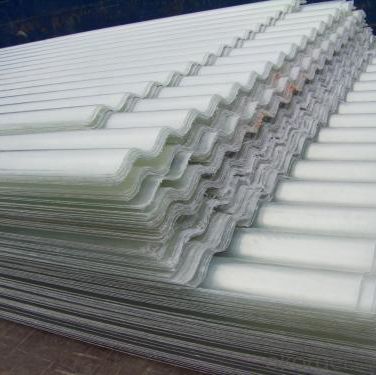

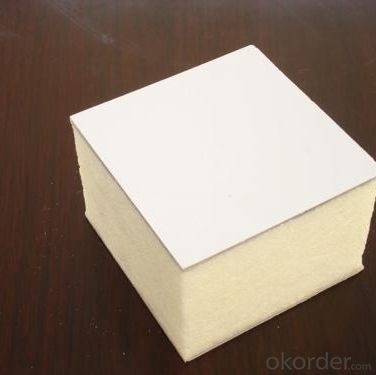

Insulated FRP Laminated Roof Panels - FRP GRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

>> Weatherability: In the temperature range of -40 ℃ - 120 ℃ to maintain stable performance, no high-temperature softening, cold brittle phenomenon;

>> Low thermal conductivity & good insulation performance;

>> Non-toxic, non-asbestos, etc., in line with world health standards;

>> No moss & prevent microbial growth;

>> High impact and resistant to strong wind;

>> Safe and reliable, Not combustion-supporting in open fire;

>> Corrosion resistance, suitable for chemical workshop roof, such as fertilizer plants, electroplating factory

SPECIFICATIONS

Item | Description | ||

| Material | FRP, ASA, PVC | ||

| Thickness | 1.0mm - 3.0mm | ||

| Color | Clear, milk white, blue, green, red | ||

| Type | 475, 666, 760, 820, 840, 860, 900, 950, 980, 1050, can be customized | ||

| Shelf life | 15 years | ||

PICTURES

- Q: Are FRP roofing panels cost-effective compared to other roofing materials?

- Cost-effectiveness can be attributed to FRP roofing panels when compared to alternative roofing materials, although this is contingent upon various factors. Homeowners and businesses find FRP panels relatively affordable for purchase and installation, making them an economically advantageous choice. Moreover, due to their lightweight nature, FRP panels require minimal structural support, subsequently reducing installation costs. In terms of long-term cost-effectiveness, FRP roofing panels offer numerous benefits. They possess an extensive lifespan, typically lasting 25-30 years or more, with minimal maintenance requirements. Consequently, the need for frequent repairs or replacement is diminished, leading to monetary savings over time. Additionally, FRP panels exhibit resistance to corrosion, rust, and weathering, thereby ensuring durability and the ability to withstand harsh environmental conditions without deterioration. Energy efficiency is another aspect that contributes to cost savings with FRP panels. These panels possess exceptional insulation properties, thereby aiding in the regulation of indoor temperatures and reducing energy consumption for heating and cooling purposes. Consequently, significant reductions in energy bills can be achieved, especially in regions characterized by extreme weather conditions. Nevertheless, it is essential to acknowledge that the cost-effectiveness of FRP roofing panels may fluctuate depending on specific project requirements and geographical location. Alternative roofing materials, such as metal, asphalt shingles, or clay tiles, may present varying costs and benefits, contingent upon factors such as local climate, building design, and aesthetic preferences. Consequently, consulting with roofing professionals and comparing different materials is advisable to determine the most cost-effective option tailored to individual needs.

- Q: Do FRP roofing panels have a specific thermal conductivity value?

- FRP roofing panels do possess a distinct thermal conductivity measurement, which is subject to variation based on the panels' individual composition and manufacturing techniques. Nevertheless, in comparison to roofing materials like metal or concrete, FRP materials typically exhibit lower thermal conductivity values. Consequently, FRP roofing panels demonstrate effective insulation qualities and contribute to diminished heat transfer between a building's interior and exterior, thus enhancing energy efficiency. To ascertain the precise thermal conductivity value of FRP roofing panels, one may refer to the manufacturer's specifications or employ suitable testing methodologies.

- Q: Are FRP roofing panels suitable for both residential and commercial buildings?

- FRP roofing panels are appropriate for both residential and commercial buildings due to their numerous advantages. Firstly, these panels are lightweight yet incredibly durable, making them a viable option for various building types. Regardless of whether it is a small residential house or a large commercial structure, FRP panels can provide dependable and long-lasting roofing solutions. Moreover, FRP panels exhibit exceptional resistance against corrosion, UV rays, and weathering. Consequently, they are particularly suitable for both residential and commercial buildings as they can endure harsh environmental conditions while maintaining their structural integrity over time. Whether it is exposure to severe weather or the requirement for long-term durability, FRP roofing panels can meet the challenge. Furthermore, FRP panels possess versatility and can be tailored to meet the specific needs of residential and commercial buildings. They are available in different sizes, colors, and designs, allowing for flexibility in architectural aesthetics. Additionally, the installation of FRP panels is straightforward, reducing the time and cost associated with roofing projects. Concerning energy efficiency, FRP panels can contribute to reducing energy consumption in both residential and commercial buildings. Their insulation properties aid in regulating temperature, minimizing the need for excessive heating or cooling. This leads to energy savings and enhanced comfort levels for occupants. In conclusion, FRP roofing panels are an appropriate choice for both residential and commercial buildings. Their lightweight yet durable nature, resistance to corrosion and weathering, versatility, and energy efficiency properties make them an outstanding option for various roofing applications.

- Q: Are FRP roofing panels resistant to bird damage?

- FRP roofing panels, also known as fiberglass reinforced plastic roofing panels, are generally resistant to bird damage. The durable nature of FRP makes it less susceptible to scratches, pecks, or punctures caused by birds compared to other roofing materials such as shingles or metal. However, it is important to note that no material is completely impervious to bird damage. In rare cases, aggressive bird behavior or large birds with strong beaks may still be able to cause some damage to FRP roofing panels. To minimize the risk of bird damage, it is advisable to make sure that the panels are properly installed, regularly inspected, and any potential bird entry points are sealed off. Additionally, taking preventive measures like using bird deterrent devices or netting can further discourage birds from perching or nesting on the roof, thereby reducing the chance of damage.

- Q: Can FRP roofing panels be used for museums?

- Yes, FRP roofing panels can be used for museums. FRP (Fiberglass Reinforced Plastic) roofing panels offer several advantages such as durability, flexibility, and resistance to corrosion, making them suitable for protecting valuable artifacts and exhibits in museums. Additionally, FRP panels can provide natural lighting and UV protection, creating a conducive environment for showcasing artwork and preserving historical items.

- Q: Can FRP roofing panels be used for outdoor arenas or stadiums?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for outdoor arenas or stadiums. FRP panels are known for their durability, strength, and resistance to weather elements, making them suitable for outdoor applications. Additionally, FRP panels are lightweight, easy to install, and offer excellent UV resistance, making them a popular choice for roofing solutions in outdoor venues.

- Q: Are FRP roofing panels resistant to tree sap or bird droppings?

- FRP roofing panels are typically resistant to tree sap and bird droppings. Due to their smooth surface, these panels do not offer a suitable area for sap or droppings to stick, simplifying the roof's cleaning and maintenance. Moreover, the chemical composition of FRP panels withstands the corrosive qualities of sap and droppings, guaranteeing the material's durability. Nevertheless, it is advisable to clean the roof periodically to prevent any accumulation or discoloration.

- Q: Are FRP roofing panels resistant to chemicals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to chemicals. FRP panels are made of a combination of fiberglass and a plastic resin, which gives them excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. This chemical resistance makes FRP roofing panels ideal for environments where exposure to chemicals is common, such as industrial facilities, laboratories, and agricultural buildings. However, it is important to note that the specific chemical resistance of FRP panels can vary depending on the specific resin formulation used and the concentration and duration of exposure to the chemicals. Therefore, it is advisable to consult with the manufacturer or supplier of the FRP panels to ensure their compatibility with the specific chemicals and conditions of your application.

- Q: Can FRP roofing panels be used for patio covers?

- Yes, FRP roofing panels can be used for patio covers. FRP (Fiberglass Reinforced Plastic) panels are durable, lightweight, and provide excellent protection against the elements. They are often used in roofing applications, including patio covers, due to their strength, resistance to corrosion, and ability to withstand harsh weather conditions.

- Q: Can FRP roofing panels be used for awnings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for awnings. FRP panels have several characteristics that make them suitable for awning applications. Firstly, they are lightweight, which makes them easy to install and handle. Secondly, FRP panels are highly durable and resistant to weathering and UV radiation, ensuring that they can withstand the elements for a long time. Additionally, FRP panels are available in various colors and designs, allowing for a wide range of aesthetic options for awning designs. Overall, FRP roofing panels provide a cost-effective and reliable solution for awnings, offering both functionality and visual appeal.

Send your message to us

Insulated FRP Laminated Roof Panels - FRP GRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords