FRP Roofing Panel - Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

The FRP roof tile using in factories, warehouses, car parks, agricultural, freezer, food processing plants, restaurants, laboratory, heat-insulation sheds, weather corridors, lighting sheds, sun sheds, greenhouses, etc.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

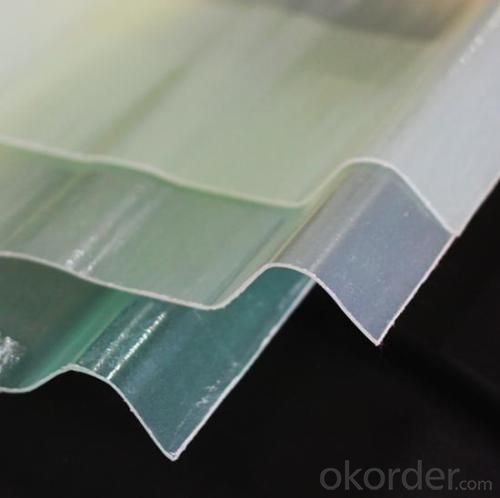

PICTURES

- Q: Are FRP roofing panels resistant to weathering?

- FRP roofing panels exhibit exceptional weather resistance, making them highly resistant to the effects of various weather conditions. These panels are specifically engineered to endure exposure to rain, snow, sun, and wind. The fiberglass reinforcement incorporated into the panels imparts robustness and longevity, rendering them impervious to cracking, warping, and fading. Moreover, FRP panels boast outstanding UV resistance, enabling them to retain their color and structural integrity even after prolonged exposure to sunlight. Consequently, these panels are widely favored for both residential and commercial purposes, offering enduring safeguarding for buildings in diverse climates.

- Q: Can FRP roofing panels be installed on top of purlins or rafters?

- Yes, FRP roofing panels can be installed on top of purlins or rafters. These panels are lightweight and versatile, making them suitable for installation on various structural support systems. As long as the purlins or rafters are properly spaced and provide adequate support, FRP roofing panels can be securely installed on top of them.

- Q: Can FRP roofing panels be used for both residential and commercial applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both residential and commercial applications. Their durability, lightweight nature, and resistance to various environmental factors make them suitable for a wide range of roofing needs in both settings.

- Q: Can FRP roofing panels be used for industrial facilities or warehouses?

- FRP roofing panels can be utilized for industrial facilities or warehouses, offering durability, strength, and resistance to different environmental factors. Their lightweight nature facilitates easy installation and transportation, while their extended lifespan surpasses that of alternative roofing materials. Moreover, FRP panels withstand corrosion, chemicals, and UV rays, making them highly suitable for facilities exposed to harsh conditions. In addition, these panels come in a range of colors and profiles, allowing for customization to meet aesthetic preferences. Ultimately, FRP roofing panels offer a cost-effective and dependable solution for industrial facilities or warehouses.

- Q: Can FRP roofing panels be used for both indoor and outdoor applications?

- Yes, FRP roofing panels can be used for both indoor and outdoor applications. FRP panels are known for their durability, weather resistance, and versatility, making them suitable for various environments and applications, including both indoor and outdoor settings.

- Q: Can FRP roofing panels be used for theaters?

- The use of FRP roofing panels in theaters is indeed possible. These panels, made from Fiberglass Reinforced Plastic, are a versatile roofing material that offers numerous advantages for theater applications. To begin with, FRP panels are lightweight, making them easy to handle and install. This is particularly advantageous in theaters where heavy machinery or equipment may be difficult to access. Additionally, their lightweight nature reduces the strain on the theater structure, making them suitable for both new construction and retrofit projects. Furthermore, FRP panels are highly durable and resistant to various environmental factors. They can withstand extreme temperatures, UV radiation, moisture, and chemicals. This durability ensures that the roofing system remains intact and functional for an extended period, reducing the need for frequent repairs or replacements. Moreover, FRP panels have excellent light transmission properties. This allows natural daylight to enter the theater space, creating a visually appealing environment and potentially reducing the need for artificial lighting during the day. Furthermore, the light transmission properties of FRP panels can be advantageous for theater performances that require specific lighting effects or color schemes. Additionally, FRP panels come in a variety of colors, finishes, and profiles, allowing for customization to meet the aesthetic requirements of the theater. They can be manufactured to resemble traditional roofing materials, such as tiles or shingles, while still retaining the benefits of FRP. In conclusion, FRP roofing panels offer a viable solution for theaters due to their lightweight nature, durability, light transmission properties, and customization options. They provide a reliable and visually appealing roofing solution that enhances the overall theater experience.

- Q: Can FRP roofing panels be used in airports or transportation hubs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can certainly be used in airports or transportation hubs. FRP panels are a popular choice for various commercial and industrial applications, including airports and transportation hubs, due to their numerous advantages. Firstly, FRP roofing panels are lightweight yet incredibly strong. This makes them suitable for large-scale structures like airports or transportation hubs where a durable roofing system is required. The lightweight nature of FRP panels also eases the installation process, reducing construction time and costs. Secondly, FRP panels are highly resistant to corrosion, chemicals, and UV radiation. This is particularly important in areas such as airports and transportation hubs, which are often exposed to harsh weather conditions and environmental factors. FRP panels can withstand extreme temperatures, rain, snow, and sunlight without deteriorating or losing their structural integrity. Additionally, FRP panels offer excellent insulation properties. They provide thermal insulation, reducing heat transfer from the outside and maintaining a comfortable interior temperature. This can contribute to energy savings and a more sustainable infrastructure. Furthermore, FRP roofing panels are available in various colors, finishes, and profiles, allowing for aesthetic customization to match the architectural style and design requirements of airports or transportation hubs. This versatility in appearance ensures that FRP panels can seamlessly integrate into the overall aesthetic of the facility. Lastly, FRP panels are low-maintenance and long-lasting. They require minimal upkeep and do not require frequent painting or sealing. This helps reduce maintenance costs and ensures the longevity of the roofing system, making it a cost-effective choice for airports or transportation hubs. Overall, FRP roofing panels possess the necessary qualities to be used in airports or transportation hubs. Their strength, durability, resistance to corrosion and UV radiation, insulation properties, aesthetic versatility, and low-maintenance nature make them a reliable and practical roofing solution for such infrastructure.

- Q: Are FRP roofing panels resistant to warping or bending from temperature changes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to warping or bending from temperature changes. The composite material used in FRP panels provides them with excellent dimensional stability and low thermal expansion properties, making them highly resistant to the effects of temperature fluctuations. This resilience allows FRP roofing panels to maintain their shape and structural integrity even in extreme weather conditions, ensuring long-lasting performance.

- Q: Are FRP roofing panels resistant to pests and insects?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to pests and insects. FRP panels are made of a composite material that is not attractive to pests and insects, such as termites, ants, and beetles. Additionally, FRP panels are manufactured in a way that does not provide any gaps or crevices where pests and insects can enter or nest. This makes FRP roofing panels an excellent choice for preventing infestations and damage caused by pests and insects.

- Q: Which is better, the sun board or the light board?

- Raw materials: in general, the production of light panels using raw materials is FRP, and the sun board (also known as hollow board), the selection of materials is PC polycarbonate;Lighting performance: both have lighting function, in which the sun plate lighting performance and weather better, while the lighting board is relatively good, acid alkaline, not easy to be acid-base corrosion;

Send your message to us

FRP Roofing Panel - Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords