FRP Corrugated Plastic Roofing Custom Design Roof with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

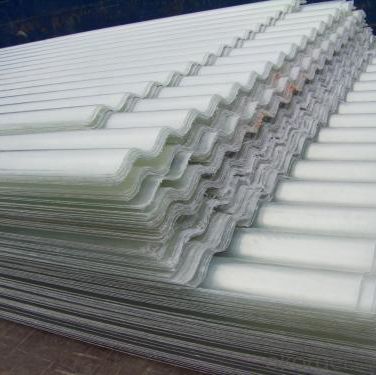

PICTURES

- Q: Are FRP roofing panels energy efficient?

- Yes, FRP roofing panels are energy efficient. FRP stands for fiberglass reinforced plastic, which is known for its excellent insulation properties. These panels can effectively regulate temperature and reduce heat transfer, resulting in lower energy consumption for cooling or heating purposes. Additionally, FRP roofing panels often have a reflective surface, which helps to deflect sunlight and reduce the amount of heat absorbed by the building. Overall, FRP roofing panels are a cost-effective and energy-efficient option for roofing systems.

- Q: Are FRP roofing panels resistant to corrosion?

- Yes, FRP roofing panels are highly resistant to corrosion. The use of fiberglass reinforced plastic (FRP) in manufacturing these panels provides excellent protection against rust and corrosion, making them an ideal choice for environments with high moisture, chemicals, or salt exposure.

- Q: Are FRP roofing panels resistant to bird damage?

- Yes, FRP roofing panels are generally resistant to bird damage. The smooth surface and durable nature of FRP panels make it difficult for birds to peck or scratch through them, protecting the roof from potential bird-related issues.

- Q: Can FRP roofing panels be used for covered walkways in theme parks or amusement parks?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for covered walkways in theme parks or amusement parks. FRP roofing panels are a popular choice for such applications due to their numerous advantages. Firstly, FRP panels are lightweight, making them easy to transport and install. This is particularly beneficial in theme parks or amusement parks where quick installation is often required. Secondly, FRP roofing panels are highly durable and resistant to various weather conditions, including sun exposure, rain, and wind. This is crucial in outdoor settings where walkways are exposed to the elements. Additionally, FRP panels are also resistant to corrosion, rot, and pests, making them a long-lasting solution for covered walkways in theme parks. Furthermore, FRP roofing panels come in a variety of colors and designs, allowing for customization to match the theme or aesthetic of the park. They can also be easily shaped and molded to fit the desired dimensions and architectural requirements. Lastly, FRP panels are known for their excellent light transmission properties. This means that even when used to cover walkways, they can still allow natural light to pass through, creating a well-lit and pleasant environment for park visitors. In summary, FRP roofing panels are a suitable and reliable option for covered walkways in theme parks or amusement parks. Their lightweight nature, durability, resistance to weather conditions, customization options, and light transmission properties make them a practical choice for creating safe and attractive walkways in these settings.

- Q: Are FRP roofing panels suitable for schools?

- Schools can benefit from using FRP roofing panels, as they are made from Fiberglass Reinforced Plastic, a durable and lightweight material commonly used in construction. These panels possess qualities that make them an ideal option for school buildings. To begin with, FRP roofing panels demonstrate exceptional resistance to weathering and corrosion. They can withstand harsh weather conditions, such as rain, snow, and UV rays, without deteriorating or fading. This durability ensures that the panels will endure for an extended period, reducing the need for frequent repairs or replacements, which is especially advantageous for schools operating on limited budgets. Moreover, FRP roofing panels are fire-resistant. They possess a high fire rating and are self-extinguishing, meaning they do not contribute to the spread of flames. This fire-resistant aspect provides an additional layer of safety for school buildings, reducing the risk of fire-related accidents and damage. Additionally, FRP roofing panels are easy to install and necessitate minimal maintenance. Due to their lightweight nature, the installation process is quicker and simpler compared to other roofing materials. Once installed, these panels require minimal upkeep, as they do not demand regular painting or sealing to uphold their appearance and performance. Furthermore, FRP roofing panels possess excellent thermal insulation properties. They aid in regulating the temperature inside the school building, reducing the reliance on heating and cooling systems. This energy-efficient quality can lead to cost savings on utility bills and contribute to a more comfortable learning environment for students and staff. In conclusion, FRP roofing panels are a suitable choice for schools due to their durability, fire resistance, low maintenance requirements, and thermal insulation properties. These panels provide long-lasting protection for school buildings, ensuring a safe and comfortable environment for students and staff while also being cost-effective in the long run.

- Q: Can FRP roofing panels be used for warehouses?

- Warehouses can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess the qualities of being lightweight, durable, and resistant to corrosion, thereby making them an exceptional selection for commercial and industrial purposes like warehouses. Moreover, they offer superb safeguarding against severe weather elements such as UV rays, rain, and snow. Furthermore, installing and upkeeping FRP panels is hassle-free, rendering them a financially prudent roofing alternative for warehouses.

- Q: Are FRP roofing panels resistant to wind uplift?

- FRP roofing panels possess a general ability to resist wind uplift. Their robust and enduring nature enables them to endure powerful gusts of wind, preventing any chances of them being lifted from the roof. These panels are specifically designed to be firmly attached to the roof structure, promoting stability and minimizing the potential for wind-related damage. Furthermore, their lightweight composition reduces the strain exerted on the roof, thereby augmenting their resistance against wind. However, it is crucial to acknowledge that the wind uplift resistance of FRP roofing panels may differ based on factors such as panel thickness, method of installation, and the severity of wind conditions. Consequently, it is always advisable to seek guidance from a professional or adhere to the manufacturer's instructions to guarantee proper installation and optimal wind resistance.

- Q: Are FRP roofing panels resistant to weathering?

- FRP roofing panels exhibit exceptional weather resistance, making them highly resistant to the effects of various weather conditions. These panels are specifically engineered to endure exposure to rain, snow, sun, and wind. The fiberglass reinforcement incorporated into the panels imparts robustness and longevity, rendering them impervious to cracking, warping, and fading. Moreover, FRP panels boast outstanding UV resistance, enabling them to retain their color and structural integrity even after prolonged exposure to sunlight. Consequently, these panels are widely favored for both residential and commercial purposes, offering enduring safeguarding for buildings in diverse climates.

- Q: Can FRP roofing panels be painted?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be painted. However, it is important to follow specific guidelines to ensure proper adhesion and longevity of the paint. Firstly, the FRP panels should be thoroughly cleaned and free of any dust, dirt, or debris. It is recommended to use a mild detergent and water solution to clean the surface. Once the panels are clean and dry, a primer designed for use on FRP should be applied. This helps the paint adhere to the surface and provides a better finish. After the primer has dried, a high-quality exterior-grade paint can be applied using a brush, roller, or spray gun. It is essential to choose a paint that is compatible with fiberglass and suitable for outdoor use. It is also advisable to apply multiple thin coats of paint rather than a thick coat to achieve a more even and durable finish. Overall, with proper preparation and the right paint products, FRP roofing panels can be successfully painted to enhance their appearance and protect them from the elements.

- Q: Are FRP roofing panels compatible with different types of flashing systems?

- Different types of flashing systems are compatible with FRP (fiberglass reinforced plastic) roofing panels. These versatile panels can be used in a range of roofing applications, from commercial to industrial and residential buildings. Integration with various types of flashing systems, including metal, PVC, or rubber flashings, is easy. To ensure a secure and watertight connection between the FRP panels and the flashing system, it is important to use proper installation techniques and compatible flashing materials. For specific recommendations and guidelines on the compatibility of FRP roofing panels with different types of flashing systems, it is advisable to consult with a professional roofing contractor or manufacturer.

Send your message to us

FRP Corrugated Plastic Roofing Custom Design Roof with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords