FRP Roofing Panel - Color Coated Metal Roof FRP Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

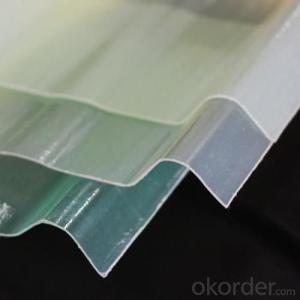

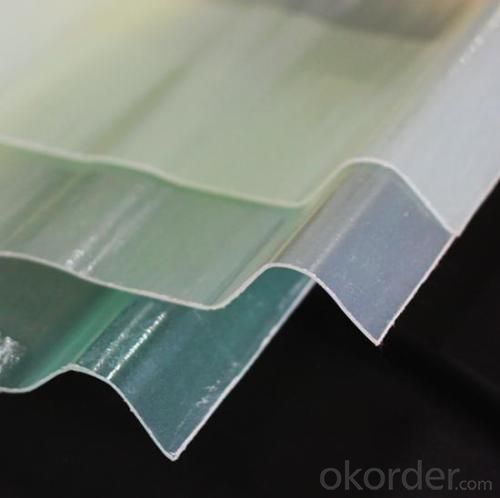

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

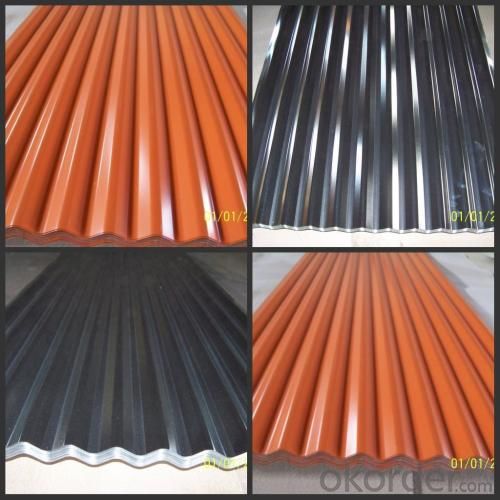

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Can FRP roofing panels be used in high-traffic areas?

- FRP roofing panels are indeed suitable for high-traffic areas due to their durability and strength. Their exceptional qualities enable them to withstand harsh weather conditions, including extreme temperatures, UV radiation, and high winds, which make them perfect for outdoor environments. Moreover, FRP panels are resistant to corrosion, chemicals, and impact, ensuring their longevity and durability. Consequently, FRP roofing panels have become a favored option for areas with heavy foot traffic, including commercial buildings, industrial facilities, sports stadiums, and public spaces, where durability and performance are of utmost importance.

- Q: Can FRP roofing panels be used in areas with high levels of industrial emissions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can generally be used in areas with high levels of industrial emissions. FRP panels are known for their durability and resistance to various chemicals, making them suitable for harsh environments including those with industrial emissions. However, it is important to consider the specific type and concentration of industrial emissions present in the area. Some industrial emissions, such as acidic gases or corrosive particles, may require additional protective coatings or special FRP formulations to ensure long-lasting performance. It is also recommended to consult with FRP manufacturers or technical experts who can provide specific guidance based on the nature of the industrial emissions and the intended use of the FRP roofing panels. Additionally, regular maintenance and inspection should be conducted to assess any potential degradation or damage caused by the industrial emissions, ensuring the continued effectiveness of the FRP roofing system.

- Q: Are FRP roofing panels resistant to discoloration from air pollution?

- FRP roofing panels exhibit remarkable resistance to discoloration caused by air pollution. Renowned for their durability and ability to withstand diverse environmental elements, including air pollution, FRP panels are equipped with an outer gel coating that serves as a safeguard against fading or discoloration resulting from exposure to airborne pollutants. Consequently, FRP roofing panels prove to be an exceptional option for regions plagued by substantial levels of air pollution, as they retain their original hue and aesthetic appeal over an extended duration.

- Q: Are FRP roofing panels energy-efficient?

- FRP roofing panels are considered energy-efficient due to their excellent insulation properties, which reduce heat transfer and maintain a consistent temperature inside the building. This insulation not only decreases the need for excessive heating or cooling but also lowers energy consumption and costs. Additionally, FRP panels allow natural light to enter the building, reducing the need for artificial lighting during the day. Moreover, FRP panels are known for their durability and longevity, requiring minimal maintenance and replacement, thus contributing further to energy efficiency. In conclusion, FRP roofing panels provide a sustainable and energy-efficient solution for building owners, enabling them to achieve energy savings and reduce environmental impact.

- Q: Are FRP roofing panels prone to cracking or warping over time?

- FRP roofing panels, renowned for their durability and resistance to cracking or warping, are constructed using a blend of fiberglass and plastic resins. This unique combination grants them exceptional strength and stability. One of the key benefits of FRP roofing panels lies in their ability to endure harsh weather conditions, including extreme temperatures, strong winds, and heavy rainfall. Unlike other roofing materials, FRP panels do not significantly expand or contract with temperature changes, thereby averting cracking or warping. Moreover, FRP panels are engineered to be lightweight yet robust, rendering them less susceptible to damage from external forces. This strength and rigidity enable the panels to maintain their shape and integrity over time, further minimizing the risk of cracking or warping. Nevertheless, it is crucial to acknowledge that the longevity and durability of FRP roofing panels can be influenced by various factors, such as the quality of materials, proper installation, and regular maintenance. Inferior or substandard panels may exhibit a greater propensity for cracking or warping. Similarly, incorrect installation or neglecting necessary maintenance, such as keeping the panels free of debris, can compromise their structural integrity. In conclusion, when FRP roofing panels are manufactured, installed, and maintained correctly, they possess a well-established reputation for being highly resistant to cracking or warping over time. Nonetheless, it is always prudent to seek guidance from professionals and adhere to the manufacturer's guidelines to ensure optimal performance and longevity of the panels.

- Q: Are FRP roofing panels suitable for residential communities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for residential communities. FRP roofing panels offer several advantages that make them a viable option for residential use. Firstly, FRP panels are lightweight, making them easier to install and transport compared to other roofing materials. This can significantly reduce installation time and costs. Secondly, FRP roofing panels are highly durable and resistant to various weather conditions, including extreme temperatures, UV rays, and moisture. This durability ensures that the roof can withstand the elements and remain intact for an extended period, reducing the need for frequent repairs or replacements. Additionally, FRP panels are fire-resistant, which is a crucial safety feature for residential communities. This fire resistance can help prevent the spread of fire in case of accidents or emergencies, providing an added layer of protection for residents. Moreover, FRP roofing panels are available in a range of colors and designs, allowing homeowners to choose a style that matches the aesthetics of their community. This versatility ensures that FRP panels can seamlessly blend into the overall architectural design of residential areas. Lastly, FRP roofing panels are cost-effective compared to other roofing materials, such as metal or asphalt shingles. The initial installation costs are often lower, and the long-term maintenance expenses are minimal due to the material's durability. This affordability can be particularly beneficial for residential communities with budget constraints or homeowners looking to reduce their overall roofing expenses. Overall, FRP roofing panels are a suitable option for residential communities due to their lightweight nature, durability, fire resistance, aesthetic versatility, and cost-effectiveness. However, it is essential to consult with roofing professionals and consider the specific needs and requirements of the community before making a final decision.

- Q: Do FRP roofing panels require special installation techniques?

- Yes, FRP roofing panels do require special installation techniques. Due to their unique composition and properties, FRP panels need to be installed carefully and precisely. This typically involves using specific tools, adhesives, and fasteners designed specifically for FRP materials. It is important to follow the manufacturer's instructions and guidelines to ensure the panels are properly installed for optimal performance and longevity.

- Q: Can FRP roofing panels be used for airports?

- Indeed, FRP roofing panels can be incorporated into airport structures. These panels possess characteristics such as being lightweight, durable, and resistant to corrosion, making them appropriate for a range of applications, including those within airports. Their strength and capacity to endure harsh weather conditions make them particularly suitable for roofing structures. Within airports, FRP roofing panels can be implemented in a variety of locations, including hangars, terminals, control towers, and other facilities. Their lightweight composition facilitates easy handling and installation, thereby reducing labor and construction expenses. Furthermore, these panels exhibit exceptional thermal insulation properties, enabling them to regulate temperatures within airport structures and consequently leading to energy conservation. Moreover, FRP roofing panels showcase resistance against UV rays, chemicals, and fire, thereby enhancing the safety and security of airport facilities. Their corrosion resistance renders them ideal for areas exposed to moisture, such as those in proximity to runways and aircraft maintenance zones. To summarize, FRP roofing panels prove to be a fitting choice for airports due to their durability, lightweight composition, resistance to corrosion, and ability to withstand a variety of weather conditions.

- Q: Can FRP roofing panels be used in areas with frequent lightning strikes?

- Yes, FRP roofing panels can be used in areas with frequent lightning strikes as they are non-conductive and do not attract or conduct electricity. This makes them a safe choice for such areas.

- Q: Can FRP roofing panels be used for stadiums?

- Certainly, stadiums can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are renowned for their exceptional durability, strength, and lightweight composition, rendering them a perfect choice for extensive undertakings such as stadiums. They possess resistance to corrosion, UV rays, and impact, ensuring a prolonged lifespan with minimal need for upkeep. Moreover, FRP panels can be tailored to meet diverse aesthetic requirements, offering an extensive array of colors and finishes to complement the stadium's design. Furthermore, their lightweight nature facilitates effortless installation, thereby reducing construction time and expenses. In summary, FRP roofing panels present a dependable, cost-efficient, and visually appealing solution for stadiums.

Send your message to us

FRP Roofing Panel - Color Coated Metal Roof FRP Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords