Frp Roof Panels Sutherland - FRP Corrugated Roofing Color Coated Metal Roof with High Quality on Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

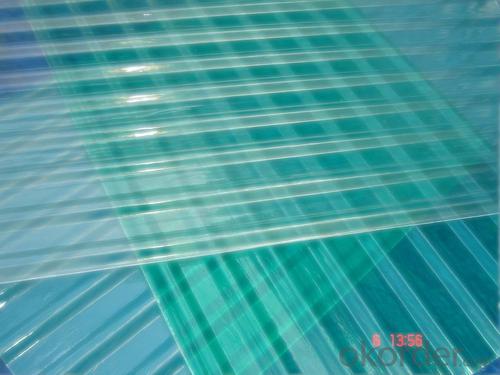

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Can FRP roofing panels be used in areas with high levels of dust or debris?

- Yes, FRP roofing panels can be used in areas with high levels of dust or debris. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability and resistance to various environmental factors. They are designed to withstand harsh conditions, including dust and debris accumulation. Additionally, the smooth surface of FRP panels makes it easier to clean and maintain, reducing the impact of dust and debris on their performance.

- Q: Can FRP roofing panels be used for canopies or shelters in outdoor parks?

- Canopies or shelters in outdoor parks can utilize FRP roofing panels. FRP, also known as fiberglass reinforced plastic, is a durable and versatile material commonly used in construction. It is favored for its strength, lightweight quality, and resistance to corrosion. These attributes make FRP roofing panels well-suited for outdoor applications, including park canopies or shelters. FRP roofing panels possess weather-resistant properties, enabling them to endure diverse environmental conditions such as rain, wind, and UV radiation. This renders them ideal for shielding individuals and equipment from the elements. In addition, FRP panels are available in various colors, shapes, and sizes, allowing for customization to match the specific requirements and aesthetic preferences of the park. Furthermore, FRP panels are easy to install and maintain, reducing the overall cost and effort necessary for upkeep. They also possess fire-resistant characteristics, which are crucial for ensuring safety in outdoor structures. Moreover, FRP roofing panels have a lengthy lifespan, enabling them to withstand outdoor elements for an extended period without significant deterioration. In summary, FRP roofing panels are a suitable option for canopies or shelters in outdoor parks due to their durability, lightweight quality, corrosion resistance, and ability to withstand diverse weather conditions. With their ease of installation and maintenance, fire resistance, and long lifespan, FRP panels provide a practical and visually appealing solution for creating functional and attractive outdoor structures in parks.

- Q: Can FRP roofing panels be used for outdoor seating areas or pavilions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for outdoor seating areas or pavilions. FRP panels are known for their durability, resistance to weather elements, and low maintenance requirements. These panels are specifically designed to withstand harsh outdoor conditions, including exposure to UV rays, rain, wind, and temperature fluctuations. The lightweight nature of FRP panels makes them easy to handle and install, making them suitable for various outdoor structures such as seating areas or pavilions. They can be easily installed on a metal or wooden framework, providing a protective cover that shields users from rain or excessive sunlight. Additionally, FRP panels are available in a variety of colors, designs, and textures, allowing for customization to match the desired aesthetic of the seating area or pavilion. They can also be translucent, allowing natural light to filter through while still providing protection from the elements. Furthermore, FRP panels are resistant to rot, rust, and corrosion, ensuring their longevity and reducing the need for frequent repairs or replacements. This makes them a cost-effective solution for outdoor seating areas or pavilions, as they require minimal maintenance over their lifespan. In summary, FRP roofing panels are an excellent choice for outdoor seating areas or pavilions due to their durability, resistance to weather elements, ease of installation, and low maintenance requirements. They offer protection from the elements while allowing for customization and aesthetics, making them a versatile option for outdoor structures.

- Q: Can FRP roofing panels be used for museums?

- Yes, FRP roofing panels can be used for museums. FRP (Fiberglass Reinforced Plastic) roofing panels offer several advantages such as durability, flexibility, and resistance to corrosion, making them suitable for protecting valuable artifacts and exhibits in museums. Additionally, FRP panels can provide natural lighting and UV protection, creating a conducive environment for showcasing artwork and preserving historical items.

- Q: Are FRP roofing panels resistant to chemical exposure from nearby industries?

- FRP roofing panels generally possess resistance to chemicals emitted by neighboring industries. FRP, an acronym for Fiber Reinforced Plastic, is created by combining fibers (like fiberglass) with a resin matrix. This composition grants FRP panels exceptional chemical resistance. The level of chemical resistance can vary depending on the specific resin utilized in the FRP panels. Nevertheless, FRP roofing panels are designed to endure exposure to a variety of industrial chemicals, including acids, alkalis, solvents, and other corrosive substances. It is essential to note that although FRP panels are resistant to most chemicals, they may not be entirely impervious to all forms of chemical exposure. Concentrated or highly corrosive chemicals may still cause gradual damage. Therefore, it is advisable to consult the manufacturer or an expert to determine the suitability of FRP roofing panels for a specific industrial setting. Apart from their chemical resistance, FRP roofing panels offer several other benefits, such as durability, lightweight construction, and resistance to UV rays. These panels are also easy to install and maintain, making them a popular choice for industrial and commercial buildings located in areas with potential chemical exposure.

- Q: What is the weight capacity of FRP roofing panels?

- The weight capacity of FRP roofing panels can differ depending on the particular product and its design. Typically, FRP roofing panels are renowned for being lightweight and possessing high strength characteristics, making them appropriate for a range of applications. The weight capacity of FRP roofing panels usually falls between 1 and 1.5 pounds per square foot. Nevertheless, it is crucial to refer to the manufacturer's specifications and guidelines for the specific FRP roofing panel in use to ascertain its precise weight capacity. Furthermore, when determining the weight capacity of FRP roofing panels, factors such as the installation method, support structure, and load distribution should also be taken into account.

- Q: Can FRP roofing panels be used for theaters?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for theaters. FRP panels are a versatile roofing material that offers several benefits for theater applications. Firstly, FRP panels are lightweight, which makes them easy to handle and install. This can be particularly advantageous in theater settings where there may be limited access to heavy machinery or equipment. The lightweight nature of FRP panels also reduces the load on the theater structure, making them a suitable choice for both new construction and retrofit projects. Secondly, FRP panels are highly durable and resistant to various environmental factors. They are capable of withstanding extreme temperatures, UV radiation, moisture, and chemicals. This durability ensures that the roofing system will remain intact and functional for an extended period, reducing the need for frequent repairs or replacements. Moreover, FRP panels offer excellent light transmission properties. This allows natural daylight to penetrate the theater space, creating a visually appealing environment and potentially reducing the need for artificial lighting during the day. Additionally, the light transmission properties of FRP panels can be advantageous for theater performances that require specific lighting effects or color schemes. Furthermore, FRP panels are available in a range of colors, finishes, and profiles, allowing for customization to suit the aesthetic requirements of the theater. They can be manufactured to mimic the appearance of traditional roofing materials, such as tiles or shingles, while still retaining the benefits of FRP. Overall, FRP roofing panels are a viable option for theaters due to their lightweight nature, durability, light transmission properties, and customization options. They provide a reliable and visually appealing roofing solution that can enhance the overall theater experience.

- Q: What is FRP roofing panel?

- FRP roofing panels, also known as fiberglass reinforced plastic roofing panels, are a type of roofing material that is composed of a combination of fiberglass and plastic resin. These panels are lightweight, durable, and have excellent resistance to corrosion, chemicals, and weathering. FRP roofing panels are commonly used in industrial and commercial buildings where strength and durability are key requirements. They are often used for applications such as warehouses, factories, agricultural buildings, and sports facilities. One of the main advantages of FRP roofing panels is their high strength-to-weight ratio. This means that they can provide a strong and reliable roofing solution while also being lightweight and easy to install. Additionally, FRP roofing panels are available in a variety of colors and finishes, allowing for customization to match the aesthetic requirements of a building. Furthermore, FRP roofing panels offer excellent thermal insulation properties, helping to regulate the temperature inside a building and reduce energy costs. They also have good light transmission, allowing natural light to enter the building, which can further reduce the need for artificial lighting during the day. In summary, FRP roofing panels are a versatile and durable roofing material that is commonly used in industrial and commercial applications. They provide strength, resistance to corrosion and weathering, thermal insulation, and light transmission, making them a popular choice for many building projects.

- Q: Are FRP roofing panels resistant to impact damage?

- Yes, FRP roofing panels are known for their excellent resistance to impact damage.

- Q: Can FRP roofing panels be used for universities?

- Certainly, universities can absolutely utilize FRP roofing panels. These panels, which are composed of Fiberglass Reinforced Plastic (FRP), boast a plethora of advantages that render them appropriate for university structures. Primarily, FRP panels possess a lightweight yet robust nature, simplifying installation while providing resilience to endure harsh weather conditions—an imperative attribute for university edifices subjected to heavy rainfall, snowfall, and gusty winds. An additional benefit of FRP roofing panels lies in their immunity to corrosion and UV rays. This characteristic grants them an extended lifespan and diminishes maintenance expenses for the university. Furthermore, FRP panels offer a high degree of customization, presenting an array of colors, styles, and finishes. This flexibility empowers universities to select panels that complement their architectural design and enhance the overall aesthetics of the campus. Furthermore, FRP roofing panels contribute to energy efficiency as they can be designed to permit natural light transmission, reducing the necessity for artificial lighting during daylight hours. This not only conserves energy but also fosters a comfortable, well-illuminated environment for students and staff. From a sustainability standpoint, FRP roofing panels are crafted from recycled materials and can be fully recycled at the conclusion of their lifecycle. This aligns with universities' mounting emphasis on environmental responsibility and aids in their green initiatives. Overall, the strength, durability, resistance to corrosion and UV rays, customizable designs, energy efficiency, and sustainability of FRP roofing panels make them an apt choice for universities.

Send your message to us

Frp Roof Panels Sutherland - FRP Corrugated Roofing Color Coated Metal Roof with High Quality on Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords