FRP Roofing Panel - Fiberglass Roofing Sheets / Corrugated Plane Skylight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP plane skylightusually use a protecting facility in construction site,steel structured workshop and warehouse,canopy,packingsheds,corridors,studio light awning and greenhouse etc as the excellent light transmittance.

FRP plane skylightis the more strengthened, safety, and more econimal greenhouse panel with the properties of waterproof,good light transmittance,heat insulation,strong impact resistant,withstand extreme temperature.

Normal thinkness:1.2mm,1.5mm,2.0mm

FEATURES

1) The fiberglass content about 27%-30%.

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5) Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

SPECIFICATIONS

Thickness | Mesh size | Panel size | Open area | Weight |

(MM) | (MM) | (MM) | % | (kg/m2) |

25 | 38*38 | 1220*3660 | 68 | 12.5 |

1220*4076 | ||||

1220*4000 | ||||

30 | 38*38 | 1220*3660 | 68 | 14.75 |

1220*4000 | ||||

38 | 38*38 | 1007*4047 | 68 | 19.5 |

1220*3660 | ||||

1220*4000 | ||||

50.7 | 50.7*50.7 | 1220*3660 | 71 | 23.5 |

1220*4000 | ||||

30 | 19*19 | 1007*4007 | 40 | 18.1 |

38 | 19*19 | 1007*4007 | 40 | 23.5 |

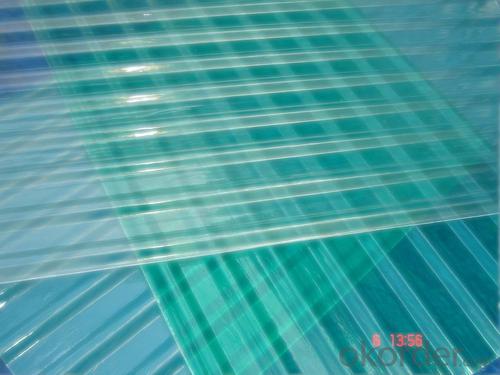

PICTURES

- Q: Are FRP roofing panels suitable for retail buildings?

- Yes, FRP roofing panels are suitable for retail buildings. FRP (Fiberglass Reinforced Plastic) roofing panels offer several advantages that make them a suitable choice for retail buildings. Firstly, FRP roofing panels are lightweight, which makes them easy to install and reduces the load on the building's structure. This is particularly beneficial for retail buildings that may have large roof areas and require a cost-effective roofing solution. Secondly, FRP roofing panels are durable and long-lasting. They are resistant to corrosion, UV radiation, and extreme weather conditions, which is crucial for maintaining the aesthetics and structural integrity of a retail building. The durability of FRP panels ensures that they can withstand the constant exposure to the elements and remain in good condition for an extended period. Additionally, FRP panels provide excellent insulation properties. They help to regulate the temperature inside the retail building, keeping it cool during hot summers and warm during cold winters. This insulation feature helps to reduce energy consumption and lower heating and cooling costs, making them an environmentally friendly choice for retail buildings. Furthermore, FRP roofing panels are available in various colors, finishes, and profiles, providing architects and designers with flexibility in terms of aesthetics. This allows retail buildings to have a visually appealing and customized roof that aligns with the brand image and overall design of the retail space. In conclusion, FRP roofing panels are well-suited for retail buildings due to their lightweight nature, durability, insulation properties, and aesthetic options. Their benefits make them a suitable choice for retail buildings where cost-effectiveness, durability, and energy efficiency are essential considerations.

- Q: Are FRP roofing panels suitable for coastal areas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for coastal areas. They are highly resistant to corrosion, saltwater, and harsh weather conditions typically found in coastal regions. Additionally, FRP panels are durable, lightweight, and provide excellent insulation, making them a reliable choice for coastal properties.

- Q: Are FRP roofing panels suitable for parking structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for parking structures. They are lightweight, durable, and resistant to corrosion, making them ideal for withstanding the constant exposure to various weather conditions in open parking areas. Additionally, FRP panels offer excellent UV resistance, ensuring long-term performance and minimal maintenance requirements. Their versatility and ease of installation also make them a cost-effective choice for parking structures.

- Q: What is the expected lifespan of FRP roofing panels?

- The expected lifespan of FRP roofing panels can vary depending on various factors such as the quality of the panels, the installation process, and the environmental conditions in which they are exposed to. However, on average, FRP roofing panels can have a lifespan of around 20 to 30 years. FRP, also known as fiberglass reinforced plastic, is a durable and lightweight material that is resistant to corrosion, UV radiation, and extreme weather conditions. This makes it a popular choice for roofing applications, especially in areas with harsh climates. Proper installation and regular maintenance are crucial for maximizing the lifespan of FRP roofing panels. Regular inspections and cleaning can help prevent the accumulation of debris, which can deteriorate the panels over time. Additionally, applying a protective coating or sealant can further enhance the longevity of the panels by providing an extra layer of protection against wear and tear. It is important to note that the lifespan of FRP roofing panels can also be influenced by the specific brand or manufacturer. Some manufacturers may offer panels with extended warranties, indicating their confidence in the longevity of their products. Therefore, it is advisable to consult with a reputable supplier or manufacturer to determine the expected lifespan of specific FRP roofing panels before making a purchase.

- Q: Are FRP roofing panels resistant to insects?

- FRP roofing panels, made of a fiberglass mat and polymer resin, possess a composition that repels insects, making them resistant to infestations. Unlike wood, FRP panels lack the elements necessary for insects to thrive, such as a food source or suitable habitat. Consequently, FRP panels remain undamaged and durable against insect-related degradation, ensuring their long lifespan. It is worth noting, however, that while FRP panels are generally impervious to insects, there exists a remote possibility of minor damage caused by certain types of insects with specialized feeding habits or aggressive behaviors. In such rare instances, it is essential to conduct regular inspections and implement appropriate pest control measures to prevent any potential issues.

- Q: Are FRP roofing panels resistant to chemicals used in agriculture?

- Yes, FRP roofing panels are generally resistant to chemicals used in agriculture. FRP (Fiberglass Reinforced Plastic) is known for its high chemical resistance, making it an ideal choice for agricultural applications where exposure to various chemicals is expected.

- Q: Can FRP roofing panels be installed on both residential and commercial car dealerships?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on both residential and commercial car dealerships. FRP panels are a versatile roofing material that offers several benefits for both types of buildings. They are lightweight, durable, and can withstand various weather conditions, making them suitable for car dealerships where protection against hail, wind, and UV rays is crucial. In residential car dealerships, FRP roofing panels can be a cost-effective and visually appealing option. They come in a range of colors and profiles, allowing homeowners to choose a design that complements their property. Additionally, FRP panels are easy to install and require minimal maintenance, making them ideal for residential applications. Similarly, in commercial car dealerships, FRP roofing panels offer numerous advantages. They are highly resistant to corrosion, which is essential in areas with high humidity or salt exposure. Moreover, their lightweight nature makes them easier to handle during installation, reducing labor costs and time. Furthermore, FRP panels provide excellent insulation properties, helping to regulate temperature and reduce energy consumption in both residential and commercial car dealerships. This can lead to cost savings in heating and cooling expenses throughout the year. Overall, FRP roofing panels are a reliable and versatile option for both residential and commercial car dealerships. Their durability, low maintenance requirements, and aesthetic appeal make them suitable for protecting vehicles and enhancing the overall appearance of the buildings.

- Q: Can FRP roofing panels be cut to fit specific dimensions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be cut to fit specific dimensions. FRP panels are known for their flexibility and can easily be cut to the desired size using basic cutting tools such as a circular saw or a jigsaw. It is important to take appropriate safety precautions while cutting FRP panels, such as wearing protective eyewear and gloves. Additionally, it is recommended to measure and mark the dimensions accurately before cutting to ensure a precise fit. Overall, FRP roofing panels offer the convenience of customization, allowing them to be easily cut to fit specific dimensions as required.

- Q: Are FRP roofing panels prone to condensation or moisture buildup?

- FRP roofing panels, also known as fiberglass reinforced plastic panels, are generally not prone to condensation or moisture buildup. Due to their composition, which combines a fiberglass layer with a plastic resin, FRP panels are highly resistant to water and moisture. The fiberglass layer provides strength and durability, while the plastic resin acts as a protective barrier against water penetration. Furthermore, FRP panels are often installed with proper ventilation systems, which help to mitigate any potential condensation issues. By allowing air to circulate between the panels and the roof structure, moisture buildup is minimized. Additionally, some FRP panels come with built-in features such as anti-condensation coatings or insulation, which further prevent the occurrence of condensation. However, it is important to note that while FRP roofing panels are generally resistant to condensation and moisture buildup, it is still crucial to ensure proper installation and maintenance. Any gaps, cracks, or improper sealing in the installation process can potentially lead to water leakage and subsequent condensation issues. Regular inspections, cleaning, and prompt repairs should be carried out to maintain the integrity of FRP roofing panels and prevent any moisture-related problems.

- Q: Do FRP roofing panels require a specific type of fastening system?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require a specific type of fastening system. The fastening system used for FRP roofing panels is typically designed to provide a secure and watertight installation. The specific type of fastening system will depend on the manufacturer's recommendations and the specific application requirements. Commonly, FRP roofing panels are fastened using screws or nails, but it is important to use the recommended fasteners provided by the manufacturer to ensure proper installation and avoid any potential damage to the panels. Additionally, the fastening system should be designed to accommodate the expansion and contraction of the FRP panels due to temperature changes, as this can affect the overall performance and lifespan of the roof. It is always advisable to consult with the manufacturer or a professional roofing contractor to determine the appropriate fastening system for FRP roofing panels based on the specific project requirements.

Send your message to us

FRP Roofing Panel - Fiberglass Roofing Sheets / Corrugated Plane Skylight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords