FRP Roofing Panel - Transparent Skylight GRP/FRP Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP Roofing Sheets usually use a protecting facility in construction site,steel structured workshop and

warehouse,canopy,packing sheds,corridors,studio light awning and greenhouse etc as the excellent light

transmittance.FRP plane skylight is the more strengthened, safety, and more econimal greenhouse panel with the properties of waterproof,good light transmittance,heat insulation,strong impact resistant, withstand extreme temperature.

FEATURES

1.Light transmission

The light transmission of FRP roof Sheet is between 60-85%. Light through FRP corrugated Sheet

scatters and is mild. It will not form a light band so as to make the indoor brighter.

2.Weather resistance

The anti-aging film covering on the surface of FRP corrugated sheet improves its property of weather

resistance. The anti- ultraviolet adsorbing agent mixing in the raw materials absorbs 99.9% of ultraviolet

ray of the visible light transmitted through the FRP sheets.

3.Corrosion resistance

The products resist various acids, alkalis and peroxides, especially suitable for application in the coastal

areas and corrosive places.Temperature performance and insulation FRP roof Sheet is a kind of hot solid

high polymer materials. It is designed for normal use in temperatures - 40℃~120℃ .The coefficient of heat

conduction of FRP roof Sheet is only 1/4 of the glass.

SPECIFICATIONS

| Name: | Fibreglass Reinforced Polyester(FRP ) Sheet |

| Material: | Protective film, Unsaturated resin polyester, Fiberglass |

| Weight: | 1800g/2400g/2750g/3050g Square meter |

| Thickness: | 0.8~3.0mm |

| Length: | Customized |

| Temp: | used in -40°c to 140 °c |

| OEM: | Welcomed |

| Color: | Clear/Blue |

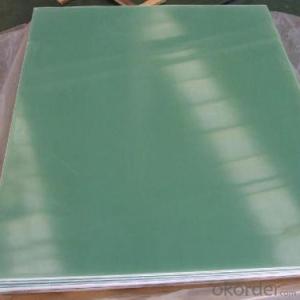

PICTURES

- Q: Can FRP roofing panels be used for covered walkways?

- Yes, FRP roofing panels can be used for covered walkways. FRP (Fiberglass Reinforced Plastic) roofing panels have several properties that make them suitable for this application. Firstly, FRP panels are lightweight, which makes them easy to install and maintain. Additionally, they are highly durable and resistant to corrosion, UV rays, and other environmental factors. This ensures that the panels will withstand the test of time and provide long-lasting protection for the covered walkways. Furthermore, FRP panels are available in various colors and designs, allowing for customization to match the aesthetic requirements of the walkway. Overall, FRP roofing panels are a reliable and cost-effective option for constructing covered walkways.

- Q: Are FRP roofing panels resistant to UV radiation?

- FRP roofing panels, in general, possess resistance against UV radiation. These panels are crafted utilizing a blend of fiberglass and plastic resin, resulting in remarkable durability and resilience against diverse environmental elements, including UV radiation. Additionally, a protective layer is often applied to these panels, further augmenting their ability to resist UV rays. Consequently, this UV-resistant coating effectively prevents the panels from becoming fragile or discolored over time due to prolonged exposure to the sun's ultraviolet rays. Ultimately, FRP roofing panels are engineered to endure the impacts of UV radiation, ensuring their structural integrity and aesthetic appeal for an extended duration.

- Q: How are FRP roofing panels installed?

- The installation of FRP roofing panels follows a series of steps to ensure a secure and weatherproof result. Here is a general outline of the installation process: 1. Planning and Preparing: Thorough planning is crucial before starting the roofing project. This involves measuring the roof area, obtaining the necessary flashing and trim materials, and acquiring all required tools and safety gear. 2. Prioritizing Safety: Safety should always be the foremost concern during installation. Installers must wear appropriate personal protective equipment (PPE), such as gloves, goggles, and non-slip shoes. Furthermore, adequate fall protection systems must be in place when working at heights. 3. Preparing the Roof Surface: The existing roof surface needs to be cleaned and cleared of any debris or loose materials. It is important to ensure that the roof is structurally sound and capable of supporting the weight of the FRP panels. 4. Installing Flashing and Trim: Flashing and trim materials are vital for preventing water penetration and providing a polished appearance. These components are typically installed first, using recommended fasteners, adhesives, or sealants. 5. Planning Panel Layout and Measurement: Before installing the FRP panels, meticulous planning of the layout and precise measurement of the roof area are crucial. This helps determine the required number and size of panels, ensuring a proper fit and minimizing waste. 6. Panel Installation: FRP panels are positioned on the roof surface and aligned according to the predetermined layout. The panels are usually secured using screws or nails, following the spacing and fastening methods specified by the manufacturer. Adhering to the recommended installation guidelines ensures proper alignment, sufficient fastening, and structural integrity. 7. Sealing and Waterproofing Panels: Joints and edges of the FRP panels must be sealed to create a watertight roof. This is typically achieved using sealants or adhesives recommended by the manufacturer. Proper sealing prevents water infiltration and safeguards the underlying roof structure. 8. Adding Finishing Touches: Once the panels are securely installed and sealed, any remaining trim or flashing components are added to complete the installation. These finishing touches enhance the overall durability of the FRP roofing system while providing a clean and professional appearance. It is important to note that the installation process may vary depending on the manufacturer's instructions, the type of FRP panels used, and the unique characteristics of the roof. Therefore, it is recommended to consult the manufacturer's installation guidelines for detailed instructions and best practices. Additionally, it is advisable to hire a professional roofing contractor experienced in FRP roofing installations to ensure a safe and reliable process.

- Q: Do FRP roofing panels require specific ventilation systems?

- No, FRP (Fiberglass Reinforced Plastic) roofing panels do not necessarily require specific ventilation systems. However, proper ventilation is important for any roofing system to ensure the longevity and performance of the roof. Good ventilation helps prevent moisture buildup, which can lead to mold and rot in the underlying structure. It also helps regulate temperature and reduce the risk of condensation. While FRP roofing panels themselves do not have any specific ventilation requirements, it is recommended to consult with a roofing professional to determine the appropriate ventilation system for your specific building and roofing design. They can assess factors such as the size of the structure, climate conditions, and usage patterns to recommend the right ventilation solution to maintain a healthy and efficient roofing system.

- Q: Can FRP roofing panels be used for both residential and commercial swimming pool enclosures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both residential and commercial swimming pool enclosures. FRP panels are highly versatile and durable, making them suitable for various applications, including pool enclosures. They offer excellent resistance to corrosion, UV rays, and chemicals typically found in pool environments. Additionally, FRP panels are lightweight, easy to install, and have high strength-to-weight ratios, making them ideal for both residential and commercial projects. Whether it is a small residential pool enclosure or a large commercial swimming pool facility, FRP roofing panels can provide a reliable and long-lasting solution.

- Q: Can FRP roofing panels be used for awnings or canopies?

- Yes, FRP roofing panels can be used for awnings or canopies. FRP (Fiberglass Reinforced Plastic) is a durable and lightweight material that is commonly used for roofing applications. Its strength and weather resistance make it suitable for creating awnings or canopies to provide shade and protect against the elements.

- Q: Are FRP roofing panels suitable for educational buildings?

- Yes, FRP roofing panels are suitable for educational buildings. They offer a range of benefits including durability, resistance to weather elements, and low maintenance requirements. Additionally, FRP panels can provide a high level of natural light transmission, which is beneficial for creating a conducive learning environment.

- Q: Are FRP roofing panels compatible with different roof drainage systems?

- Indeed, FRP roofing panels can be used alongside a variety of roof drainage systems. With their versatility, FRP panels can be adjusted to function with different types of drainage systems, including gutters, downspouts, and scuppers. Integration of these panels into an existing drainage system or the creation of new drainage installations is a simple task. The customizable nature of FRP ensures smooth incorporation, rendering it an excellent option for diverse roof drainage systems.

- Q: Can FRP roofing panels be used for stadiums?

- Certainly, stadiums can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are renowned for their exceptional durability, strength, and lightweight composition, rendering them a perfect choice for extensive undertakings such as stadiums. They possess resistance to corrosion, UV rays, and impact, ensuring a prolonged lifespan with minimal need for upkeep. Moreover, FRP panels can be tailored to meet diverse aesthetic requirements, offering an extensive array of colors and finishes to complement the stadium's design. Furthermore, their lightweight nature facilitates effortless installation, thereby reducing construction time and expenses. In summary, FRP roofing panels present a dependable, cost-efficient, and visually appealing solution for stadiums.

- Q: Are FRP roofing panels resistant to warping or sagging due to heat?

- Yes, FRP roofing panels are highly resistant to warping or sagging due to heat. The composition of fiberglass reinforced plastic (FRP) provides excellent thermal stability, making these panels well-suited for withstanding high temperatures without distorting or deforming.

Send your message to us

FRP Roofing Panel - Transparent Skylight GRP/FRP Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords