Hobby Wood Aluminum Sheets - Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox

1.Structure of Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

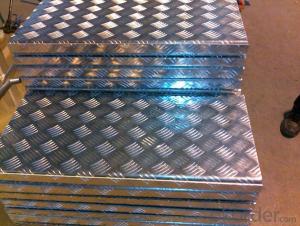

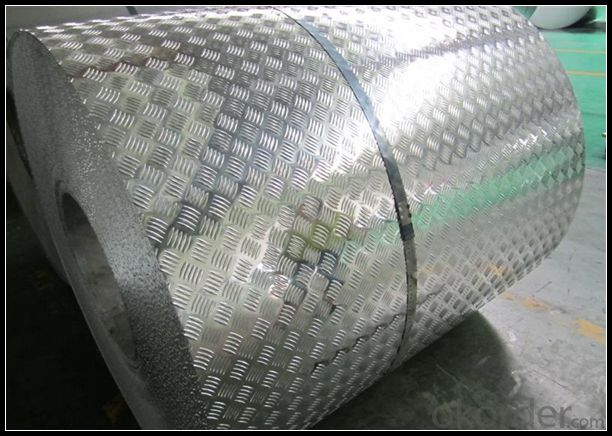

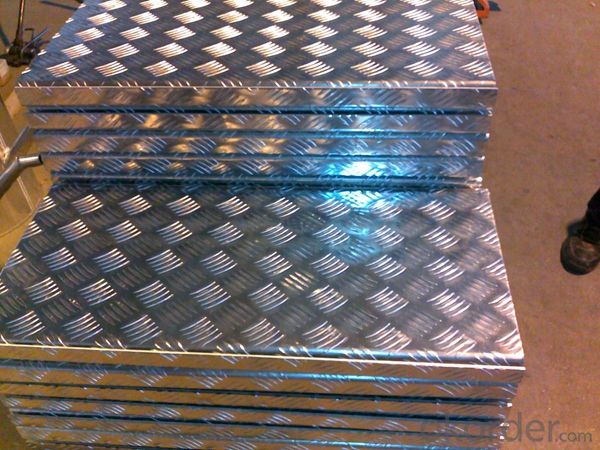

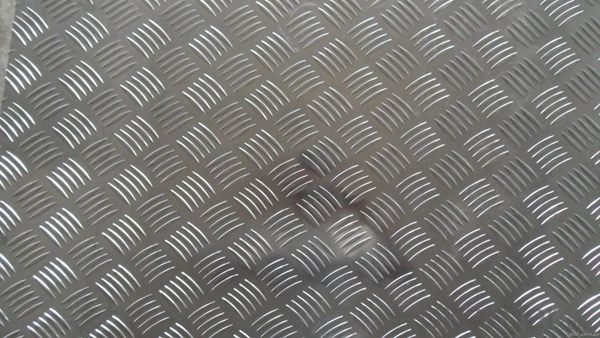

3. Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox Images

4.Specification of Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: Can aluminum plate resist acid and alkali?

- Acid base corrosion aluminum alloy, corrosion resistance, but nothing is absolute, even if the steel plate in the long-term corrosion of acid and alkali will also have problems

- Q: What are the different types of finishes used for decorative aluminum sheet?

- The different types of finishes used for decorative aluminum sheet include brushed, polished, anodized, embossed, and powder coated finishes.

- Q: Does anyone know anything about the value of aluminum can(beer, soda, etc.) pull tabs? I have heard a rumor that the tabs are worth more than the cans and that a gallon jug of tabs can be sold at recycling centers for several hundred dollars.Anyone know if this is really true?

- they are none too bright!! We save pull tabs for our church, we find that saving the tab is worth more than the whole can! The can requires a lot of storage while you can get a denser pack into a 55 gal drum with just the tabs. I do not know the current price of aluminum per pound. I do not know the weight of a gallon jug filled with pull tabs SORRY! I do know that the other posters have no idea of what they say or think they know. All I can say, is start collecting and weigh it when you are done. I do know that our church finds this a worthy project, they make a bunch of money for something that would be trashed or otherwise disposed of... FYI, a black bag filled with cans will get you about $8.00US

- Q: Can the aluminum sheets be used for manufacturing electrical conductors?

- Yes, aluminum sheets can be used for manufacturing electrical conductors. Aluminum is a highly conductive metal, second only to copper in terms of electrical conductivity. It is widely used in various electrical applications, including power transmission lines, electrical cables, and wiring. Aluminum sheets can be rolled or extruded into different shapes and sizes to suit specific conductor requirements. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective compared to other conductive materials, making it a popular choice for electrical conductor manufacturing.

- Q: Can aluminum sheets be embossed or textured?

- Aluminum sheets are indeed capable of being embossed or textured. To achieve this, specialized machinery is employed to press or roll the sheet, thereby creating patterns or designs on its surface. The purpose of embossing or texturing aluminum sheets can be twofold: enhancing the sheet's aesthetic appeal or enhancing its functionality by providing grip or augmenting its strength. These embossed or textured aluminum sheets find widespread usage across different industries, including automotive, interior design, and packaging.

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Copper Aluminum Alloy

- Q: Are aluminum sheets suitable for industrial machinery?

- Yes, aluminum sheets are suitable for industrial machinery. Aluminum is a versatile and widely used material in various industries, including machinery and manufacturing. Aluminum sheets offer several advantages that make them suitable for use in industrial machinery. Firstly, aluminum sheets are lightweight. Compared to other metals like steel, aluminum has a significantly lower density, making it ideal for applications where weight reduction is important. The lightweight nature of aluminum allows for easier handling, transportation, and installation of machinery components, resulting in higher efficiency and lower costs. Secondly, aluminum sheets are highly corrosion resistant. Aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This resistance to corrosion makes aluminum sheets suitable for use in industrial machinery, especially in environments where exposure to moisture, chemicals, or harsh weather conditions is common. Additionally, aluminum sheets have excellent thermal conductivity. This property allows aluminum to quickly and efficiently dissipate heat, making it suitable for applications where machinery components generate significant heat. By effectively managing heat, aluminum sheets help prevent overheating and prolong the lifespan of machinery. Furthermore, aluminum sheets are easily formable and can be fabricated into various shapes and sizes, making them adaptable to different machinery designs and requirements. They can be easily machined, welded, and joined, allowing for easy integration into industrial machinery manufacturing processes. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, reducing the environmental impact of industrial machinery production and disposal. In conclusion, aluminum sheets are suitable for industrial machinery due to their lightweight nature, corrosion resistance, thermal conductivity, formability, and sustainability. These qualities make aluminum sheets an excellent choice for various applications in the machinery and manufacturing industries.

- Q: What is the electrical resistivity of 101 aluminum sheets?

- The electrical resistivity of 101 aluminum sheets would depend on multiple factors, such as the thickness, purity, and temperature of the sheets. Without specific information about these factors, it is not possible to provide a precise answer.

- Q: I want to make a dress from aluminum cans. However, aluminum is very sharp once cut. So, do you thing there is a possible way to make the cut edges less sharp? Would sanding the edges help?

- . The cans will always be sharp. It is possible sand or file aluminum, you will need a brush to clean the sandpaper on file. You could try folding edges to possibly remove some of the some of the sharpness.

Send your message to us

Hobby Wood Aluminum Sheets - Mill Finish Five Bar Aluminium Treadplates 5052 HO for Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords