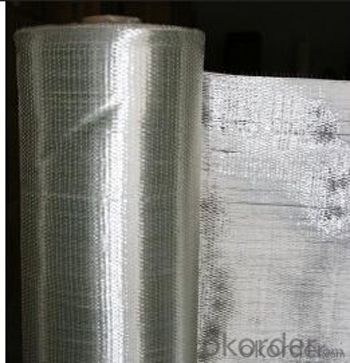

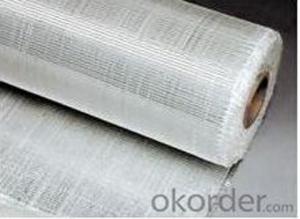

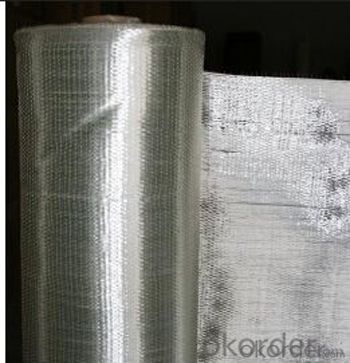

Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1524mm Length

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Unidirectional Fabric with Density 600gsm Length 1524mm

Description

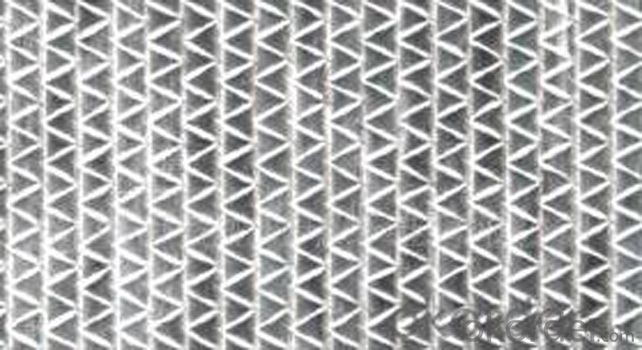

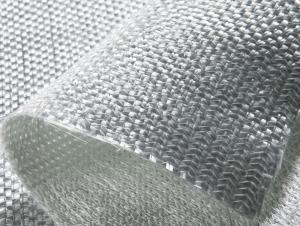

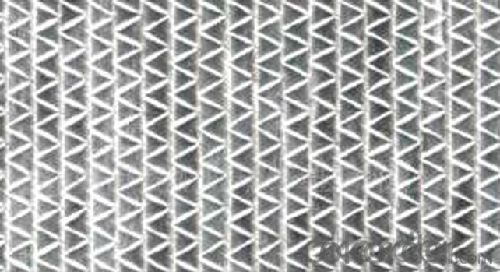

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Features

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Image:

Features

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control systempment;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before ship

d, Sample stock for one year for quality tracing and record.

- Q: What are the common sizes available for fiberglass mat tissue?

- The common sizes available for fiberglass mat tissue vary, but typically range from 1.27 meters (50 inches) to 2.54 meters (100 inches) in width, and can be customized to desired lengths by manufacturers.

- Q: How does fiberglass mat tissue perform in terms of chemical resistance?

- Fiberglass mat tissue is renowned for its exceptional chemical resistance capabilities. This material is typically composed of glass fibers held together by a binder, enabling it to withstand a wide range of chemicals. This makes it a popular choice as a reinforcement in composite materials, like fiberglass-reinforced plastics (FRP), as it can endure exposure to various chemicals without degradation. The level of chemical resistance in fiberglass mat tissue can vary depending on its specific type, quality, and the chemicals it encounters. However, it generally exhibits high resistance to acids, alkalis, solvents, and other corrosive substances. This quality makes it suitable for applications where the material may come into contact with aggressive chemicals, such as in chemical processing plants, water treatment facilities, or storage tanks. It is important to acknowledge that while fiberglass mat tissue is generally chemically resistant, it may not be completely impervious to all chemicals. Certain highly concentrated or specialized chemicals may still have the potential to cause damage or deterioration over time. Therefore, it is always advisable to consult the manufacturer's specifications and recommendations for detailed information on chemical resistance before utilizing fiberglass mat tissue in a particular application. All in all, fiberglass mat tissue's robust chemical resistance properties establish it as a dependable option for applications involving chemical exposure.

- Q: Does fiberglass mat tissue require any maintenance?

- Fiberglass mat tissue does not typically require any maintenance once it has been installed. This material is designed to be durable and long-lasting, capable of withstanding various environmental conditions. Unlike other materials, fiberglass mat tissue is resistant to rot, corrosion, and decay, making it a low-maintenance option for many applications. However, it is important to note that proper installation is crucial to ensure the longevity and effectiveness of fiberglass mat tissue. It should be installed according to manufacturer guidelines, ensuring that it is properly bonded and sealed to the surface. This will help prevent any potential issues or damage that may arise from improper installation. In some cases, fiberglass mat tissue may require occasional cleaning to remove any dirt or debris that may accumulate over time. This can be done using mild soap and water, or by following the manufacturer's recommended cleaning instructions. Overall, while fiberglass mat tissue does not require regular maintenance, it is important to address any issues or damages promptly to prevent further deterioration. Regular inspections and necessary repairs should be carried out to ensure the continued performance and longevity of the material.

- Q: Is fiberglass mat tissue suitable for railway infrastructure?

- Yes, fiberglass mat tissue is suitable for railway infrastructure. It is a versatile material that offers excellent mechanical strength, durability, and corrosion resistance. It can be used for various applications in railway infrastructure, including reinforcement of concrete structures, insulation, and protection against fire hazards. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a cost-effective choice for railway projects.

- Q: Is fiberglass mat tissue suitable for insulation in sports facilities?

- Fiberglass mat tissue is indeed suitable for insulation in sports facilities. Fiberglass is a commonly used material for insulation due to its excellent thermal properties and fire resistance. It provides effective insulation, keeping the indoor environment comfortable by reducing heat loss or gain. Additionally, fiberglass insulation is lightweight, durable, and easy to install, making it ideal for sports facilities where large areas need to be insulated. It is also resistant to moisture and does not promote the growth of mold or mildew, ensuring a healthy and hygienic environment. Overall, fiberglass mat tissue is a reliable and efficient option for insulation in sports facilities.

- Q: Is fiberglass mat tissue suitable for automotive panel repairs?

- Yes, fiberglass mat tissue is suitable for automotive panel repairs. Fiberglass mat tissue is a versatile and durable material that is commonly used in automotive repairs. It is particularly effective for repairing and reinforcing damaged or weakened areas on automotive panels. Fiberglass mat tissue provides a strong and stable foundation for repairing dents, cracks, or holes in panels, and it can be easily shaped and molded to fit the contours of the panel. Additionally, fiberglass mat tissue is resistant to rust and corrosion, making it a reliable choice for automotive repairs that need to withstand harsh weather conditions and road debris. Overall, fiberglass mat tissue is a suitable and widely-used material for automotive panel repairs due to its strength, durability, and versatility.

- Q: How does fiberglass mat tissue compare to other reinforcing materials, such as carbon fiber or kevlar?

- Fiberglass mat tissue is a reinforcing material that offers several advantages compared to other materials like carbon fiber or Kevlar. While carbon fiber is known for its excellent strength and stiffness, fiberglass mat tissue provides a more cost-effective solution with good strength-to-weight ratio. It is also highly resistant to corrosion, making it suitable for various applications. On the other hand, Kevlar is popular for its exceptional strength and impact resistance, but it is generally more expensive than fiberglass mat tissue. Therefore, the choice between these reinforcing materials depends on the specific requirements of the project, considering factors like cost, strength, stiffness, and corrosion resistance.

- Q: Is fiberglass mat tissue suitable for insulation in residential buildings?

- Residential buildings find fiberglass mat tissue to be a suitable option for insulation. This insulation material, made from glass fibers, is commonly used because of its exceptional thermal properties. With a high R-value, it effectively reduces heat transfer, keeping interiors warm in winter and cool in summer. In addition to its thermal efficiency, fiberglass mat tissue is renowned for its durability and long lifespan, making it a reliable choice. It resists moisture, mold, and pests, ensuring a healthy and comfortable living environment. Moreover, its lightweight nature and easy installation process make it efficient and cost-effective for insulation purposes. Moreover, fiberglass mat tissue possesses the crucial feature of being fire-resistant, which is highly desirable for residential buildings. It acts as a protective barrier, preventing the spread of fire and safeguarding occupants and property from potential hazards. Overall, fiberglass mat tissue is a popular and appropriate option for residential insulation due to its thermal efficiency, durability, fire resistance, and easy installation.

- Q: Can fiberglass mat tissue be used for wall insulation?

- Wall insulation can indeed utilize fiberglass mat tissue. This lightweight and flexible material is frequently employed for thermal and acoustic insulation in buildings. It is composed of fine glass fibers that are woven together to form a mat. This mat is subsequently used as an insulation layer, either in the form of rolls or batts, which is positioned between the wall structure and the finished wall surface. The efficacy of fiberglass mat tissue as an insulation material derives from its high resistance to heat transfer. It effectively prevents heat loss during winter and heat gain during summer, thereby reducing energy consumption and maintaining a comfortable indoor temperature. Additionally, it functions as a sound barrier, diminishing noise transmission between rooms and from external sources. Moreover, fiberglass mat tissue is non-combustible, meaning it does not contribute to the spread of fire. Consequently, it is a safe choice for wall insulation, as it hinders the progression of a fire and allows occupants valuable time to evacuate. Aside from its insulation properties, fiberglass mat tissue is also simple to install. It can be easily cut to size and fitted into wall cavities, ensuring a snug and efficient insulation layer. Furthermore, it is durable and long-lasting, providing insulation benefits for many years. In summary, fiberglass mat tissue is a suitable option for wall insulation due to its thermal and acoustic properties, fire resistance, ease of installation, and durability.

- Q: What are the potential health hazards associated with working with fiberglass mat tissue?

- There are several potential health hazards that can arise from working with fiberglass mat tissue due to its nature. One major concern is the inhalation of fiberglass particles, which can lead to respiratory problems. When fiberglass is cut or handled, it releases small particles into the air that are easily breathed in. Breathing in these particles for a prolonged period can cause irritation in the throat and lungs, as well as coughing and difficulty breathing. Another health hazard associated with fiberglass mat tissue is skin irritation. The tiny fibers from the material can cause redness, itching, and rashes when they come into contact with the skin. In some cases, prolonged exposure or repeated contact with fiberglass can result in more serious skin conditions like dermatitis. Furthermore, fiberglass mat tissue can also cause irritation and damage to the eyes. If the fibers come into contact with the eyes, they can cause redness, itching, watering, and even scratches on the cornea. It is important to wear appropriate eye protection, like goggles, to prevent any potential eye injuries when working with fiberglass. To minimize these potential health hazards, it is crucial to adhere to safety guidelines and use personal protective equipment (PPE) when working with fiberglass mat tissue. This includes wearing a respirator mask to prevent inhalation of particles, using gloves and protective clothing to reduce skin contact, and wearing safety goggles to protect the eyes. Regular cleaning and good hygiene practices are also essential to minimize any potential health risks associated with fiberglass. It is important to properly clean work areas to remove loose fibers, and to thoroughly wash hands and exposed skin after working with fiberglass. Overall, although working with fiberglass mat tissue can pose potential health hazards, taking appropriate safety precautions and following safety guidelines can greatly reduce the risk of any negative health effects.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1524mm Length

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords