Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

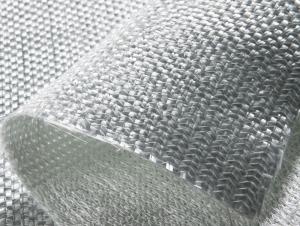

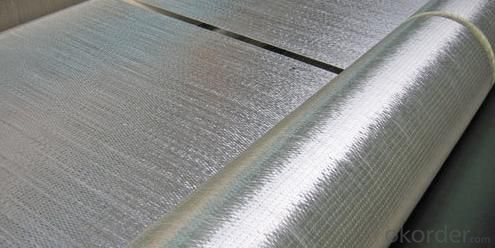

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.It is mainly used as reinforced materials in the composite material industry.

2.Properties

Fiber straight arranged, fiber strength be ultimately used.

No powder or emulsion, sink quickly, easy to operate.

Easy to design, high strength in one direction.

3.Technical Specification

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

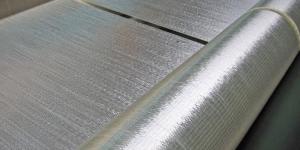

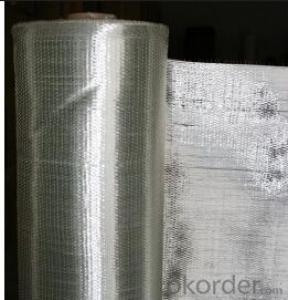

Packaging: Wrapped in PVC and placed within a cardboard carton.

4.FAQ

a. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

b. What is your MOQ?

Our MOQ is one pallet.

c. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

d. Payment terms?

We can accept L/C, T/T etc.

- Q: Can fiberglass mat tissue be used for repairing fiberglass structures?

- Fiberglass structures can be repaired using fiberglass mat tissue. This material is widely used in the construction and repair of fiberglass structures because of its versatility. Its purpose is to strengthen and reinforce damaged areas of the structure. To ensure a durable repair, the mat tissue is usually applied with resin, which bonds the fibers together. It is particularly effective for fixing cracks, holes, and other damages on fiberglass surfaces. In summary, fiberglass mat tissue is an outstanding option for repairing fiberglass structures due to its strength, flexibility, and ability to adapt to different shapes and sizes.

- Q: Can fiberglass mat tissue be used for lightweight construction?

- Yes, fiberglass mat tissue can be used for lightweight construction. It is a versatile material that offers high strength-to-weight ratio, making it suitable for various applications where weight reduction is desired without compromising structural integrity. Its lightweight nature enables easier handling, installation, and transportation, making it an ideal choice for lightweight construction projects.

- Q: Can fiberglass mat tissue be used for HVAC ducting?

- Yes, fiberglass mat tissue can be used for HVAC ducting.

- Q: Is fiberglass mat tissue resistant to moisture vapor transmission?

- Indeed, fiberglass mat tissue exhibits resistance to the transmission of moisture vapor. It serves as a remarkably robust and moisture-resistant substance, frequently employed in a multitude of scenarios that prioritize moisture management, including roofing, insulation, and flooring. The design of the fiberglass mat tissue is specifically tailored to impede the passage of moisture vapor, thereby preserving the quality and functionality of the accompanying materials. Given its capacity to resist the transmission of moisture vapor, the fiberglass mat tissue emerges as an optimal selection for environments where moisture control is of utmost importance.

- Q: Is fiberglass mat tissue suitable for insulation in food processing facilities?

- Fiberglass mat tissue is not suitable for insulation in food processing facilities. This material is typically used as a reinforcement in composites, such as roofing and construction materials, and is not designed to meet the specific requirements of food processing environments. Food processing facilities require insulation materials that are safe, durable, and compliant with strict health and safety regulations. Fiberglass mat tissue does not possess these characteristics and may pose potential risks to food safety. Instead, it is recommended to use insulation materials specifically designed for food processing facilities. These materials should be non-toxic, resistant to moisture, mold, and bacteria, and should be able to withstand high temperatures and frequent cleaning and sanitization procedures. Examples of suitable insulation materials for food processing facilities include closed-cell foam, mineral wool, and polyisocyanurate (PIR) foam. These materials have been extensively tested and proven to meet the necessary standards and regulations for use in food processing environments. It is crucial to prioritize the safety and hygiene of food processing facilities, and therefore, it is advisable to consult with experts or insulation specialists who can provide guidance on the most suitable and compliant insulation options for such facilities.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue, also referred to as fiberglass mat or fiberglass matting, is a non-woven material made from glass fibers, possessing numerous properties that render it suitable for diverse applications. 1. With regards to strength and durability, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure substantial stress without fracturing. This quality makes it ideal for fortifying and reinforcing various materials and structures. 2. Despite its strength, fiberglass mat tissue remains relatively lightweight, facilitating easy handling and transportation. This characteristic proves particularly advantageous in industries where weight reduction plays a crucial role, such as aerospace and automotive. 3. The flexibility of fiberglass mat tissue allows it to conform to curved surfaces and intricate shapes. Consequently, it proves versatile and appropriate for applications requiring the material to be molded or shaped into specific designs. 4. Fiberglass mat tissue exhibits excellent resistance to various chemicals, including acids, alkalis, and most solvents. This attribute renders it suitable for use in corrosive environments, such as chemical processing plants or storage tanks. 5. Fiberglass mat tissue possesses commendable thermal insulation properties, effectively reducing heat transfer. Consequently, it proves valuable in applications necessitating heat insulation, such as the construction of walls, roofs, or insulation boards. 6. Inherently fire-resistant, fiberglass mat tissue does not contribute to the propagation of flames. As a result, it finds extensive use in applications where fire safety is paramount, such as the production of fire-resistant doors, panels, or insulation materials. 7. Furthermore, fiberglass mat tissue offers excellent sound insulation properties, diminishing the transmission of noise through walls or other structures. This characteristic renders it suitable for implementation in soundproofing applications, such as recording studios or automotive interior panels. Overall, the properties exhibited by fiberglass mat tissue endow it with versatility, allowing for a wide range of applications across various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight nature, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in numerous applications.

- Q: Can fiberglass mat tissue be used in structural applications?

- Yes, fiberglass mat tissue can be used in structural applications. It is commonly used as a reinforcement material in composites, such as in the construction of building panels, automotive parts, and boat hulls. The high strength and stiffness properties of fiberglass mat tissue make it suitable for providing structural integrity and enhancing the overall strength of various applications.

- Q: What is the shear strength of fiberglass mat tissue?

- Various factors, including the mat's thickness, the type and quality of the fiberglass material, and the manufacturing process, determine the shear strength of fiberglass mat tissue. Generally, fiberglass mat tissue possesses a higher shear strength compared to other materials. Typically, fiberglass mat tissue consists of multiple layers of glass fibers bonded together with a resin matrix. This combination yields a robust and long-lasting product. The high shear strength of fiberglass mat tissue enables it to withstand significant forces and resist deformation or failure under shear stress. To determine the specific shear strength of a particular fiberglass mat tissue, one must refer to the manufacturer's product specifications. These specifications outline the material's shear strength and other mechanical properties. It is crucial to note that the shear strength of fiberglass mat tissue may vary depending on the specific application and conditions. Factors like temperature, moisture, and exposure to chemicals can affect the material's performance. Therefore, it is advisable to consult the manufacturer's guidelines and seek advice from engineering experts to ensure the appropriate selection and application of fiberglass mat tissue for a given project.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Yes, fiberglass mat tissue can be used for reinforcing concrete. It is often used as a reinforcement material in construction for its high tensile strength and durability. The fiberglass mat tissue helps to increase the overall strength and structural integrity of the concrete, making it suitable for various applications such as building foundations, road pavements, and precast concrete products.

- Q: Does fiberglass mat tissue require any surface preparation before application?

- Yes, fiberglass mat tissue typically requires some surface preparation before application. This is to ensure proper adhesion and bonding between the fiberglass mat tissue and the surface it is being applied to. The exact surface preparation required may vary depending on the specific application and the condition of the surface. However, some common steps in surface preparation for fiberglass mat tissue include cleaning the surface to remove any dirt, grease, or other contaminants, sanding or roughening the surface to create a better bonding surface, and applying a primer or other bonding agent if necessary. It is important to carefully follow the manufacturer's instructions and recommendations for surface preparation to ensure the best results and optimal performance of the fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords