Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

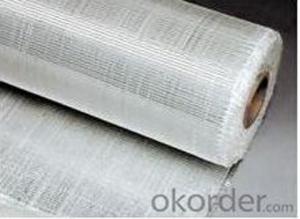

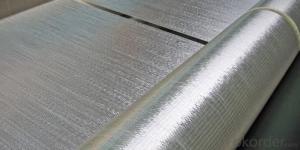

Structure of Fiberglass Multiaxial Fabric-UD Description:

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Main Features of the Fiberglass Multiaxial Fabric-UD:

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Fiberglass Multiaxial Fabric-UD Images:

Unidirectional Specification:

specifications | Fibre type | 0°Roving | 90°Roving | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EDW227 | E-Glass | — | 227 | 227 | 1524 |

EDW350 | E-Glass | — | 350 | 350 | 1524 |

EDW450 | E-Glass | — | 450 | 450 | 1524 |

EDJ600 | E-Glass | 480 | 120 | 600 | 1524 |

EDJ800 | E-Glass | 600 | 200 | 800 | 1524 |

EDJ1000 | E-Glass | 600 | 400 | 1000 | 1524 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

- Q: Can fiberglass mat tissue be used for architectural applications?

- Yes, fiberglass mat tissue can be used for architectural applications. It is commonly used as a reinforcing material in architectural elements such as roofing, insulation, and wall panels. Its high strength, durability, and fire resistance make it suitable for various architectural purposes.

- Q: What is the tear strength of fiberglass mat tissue?

- The ability of fiberglass mat tissue to resist tears or cracks when exposed to external forces is referred to as its tear strength. This characteristic plays a crucial role in determining the durability and performance of fiberglass mat tissue in different applications. Standardized testing methods, such as the ASTM D1922 tear resistance test, are typically used to measure the tear strength of fiberglass mat tissue. This test involves applying a controlled force, usually in the form of a tensile load, to a sample of the material and measuring the amount of force required to cause a tear or rupture. The tear strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, the quality of the raw materials used, and the specific requirements of the application. Generally, fiberglass mat tissues are designed to have high tear strength in order to withstand the stresses and strains encountered during installation and use. Fiberglass mat tissue finds widespread use in industries like construction, automotive, aerospace, and marine, thanks to its high tear strength and other desirable properties. It is commonly employed as a reinforcement material in composites, providing increased strength and durability to the final product. In summary, the tear strength of fiberglass mat tissue is a vital property that determines its ability to resist tearing or cracking when subjected to applied forces. By ensuring a high tear strength, fiberglass mat tissue can meet the demands of various applications and deliver long-lasting performance.

- Q: What are the different types of resins compatible with fiberglass mat tissue?

- There are several types of resins that are compatible with fiberglass mat tissue, including polyester resin, epoxy resin, and vinyl ester resin. These resins provide different properties and characteristics to the fiberglass mat, such as strength, durability, and resistance to chemicals or UV degradation. The choice of resin depends on the specific application and desired performance of the fiberglass product.

- Q: Can fiberglass mat tissue be used for insulating exterior walls?

- Insulating exterior walls can be done using fiberglass mat tissue. This particular type of insulation material is commonly chosen for its exceptional thermal and acoustic insulation properties. It is composed of fine glass fibers that are bonded together with a binder, resulting in a lightweight and flexible material. When applied to insulate exterior walls, fiberglass mat tissue is typically installed either between the wall studs or in the wall cavities. By trapping air within its fibers, it effectively reduces heat transfer and acts as a barrier against heat loss or gain. This insulation material plays a significant role in enhancing a building's energy efficiency by reducing the need for heating or cooling, thus leading to lower energy costs and carbon emissions. In addition to its insulating properties, fiberglass mat tissue is also resistant to moisture, mold, and mildew, which makes it suitable for external applications. It contributes to creating a more comfortable and healthier indoor environment by preventing the growth of harmful microorganisms and minimizing condensation. Furthermore, it provides an extra layer of safety to the building as it is fire-resistant. To summarize, fiberglass mat tissue is a versatile and efficient insulation material that can be utilized for insulating exterior walls. Its exceptional thermal and acoustic properties, resistance to moisture and fire, make it an excellent choice for improving the energy efficiency and comfort of buildings.

- Q: Can fiberglass mat tissue be used in wet environments?

- Yes, fiberglass mat tissue can be used in wet environments. It is resistant to water and can withstand exposure to moisture without losing its structural integrity.

- Q: Can fiberglass mat tissue be used for electrical enclosures?

- Typically, fiberglass mat tissue is not employed in the construction of electrical enclosures. These enclosures are specifically designed to shield electrical equipment against external elements including dust, moisture, and physical harm. Usually, materials with excellent insulation and high mechanical strength, such as sheet metal, plastic, or fiberglass reinforced plastic (FRP), are used for their manufacture. Although fiberglass mat tissue can offer certain levels of mechanical strength and insulation, it is not commonly utilized as the main material for electrical enclosures due to its restricted durability and lower resistance to moisture and impact.

- Q: What about high temperature fiberglass?

- Yes. Glass fiber should be bought or broken. Because very thin, eat in, of course not good, but can not digest, theory can be discharged.The temperature does not break the glass fiber but softens and breaks it first. It needs 600 degrees or more!

- Q: How is fiberglass mat tissue used in the automotive industry?

- Fiberglass mat tissue is commonly used in the automotive industry as a reinforcement material. It is typically applied to the surface of automotive parts, such as hoods, roofs, and doors, to enhance their strength and durability. The fiberglass mat tissue helps to improve the overall structural integrity of the vehicle, making it more resistant to impact and reducing the risk of damage. Additionally, it also contributes to noise reduction and vibration damping, resulting in a smoother and quieter ride for the occupants.

- Q: Is fiberglass mat tissue resistant to mildew and rot?

- Indeed, the resistance of fiberglass mat tissue to mildew and rot is undeniable. Crafted from delicate glass fibers interlaced to form a robust and enduring substance, fiberglass stands as a paragon. Its non-porous nature prevents moisture absorption, thus endowing fiberglass mat tissue with exceptional resistance against mildew proliferation and rot-induced decomposition. Moreover, fiberglass often receives protective coatings or additives that amplify its fortitude against these biological detriments. For this reason, fiberglass mat tissue emerges as an exemplary selection in settings where humidity or moisture pose a threat, such as bathrooms, outdoor structures, or regions prone to elevated humidity levels.

- Q: How does fiberglass mat tissue compare to spray foam insulation?

- Fiberglass mat tissue and spray foam insulation are two different types of insulation materials with their own unique characteristics and benefits. Fiberglass mat tissue is a type of insulation made from woven strands of fiberglass. It is typically used in applications where thermal insulation is required, such as in walls, roofs, and attics. Fiberglass mat tissue is known for its high resistance to heat transfer, making it an effective insulator. It is also fire-resistant, which adds an additional safety benefit. On the other hand, spray foam insulation is a type of insulation that is applied as a liquid and expands into a solid foam. It can fill in small cracks and gaps, creating an airtight seal, which makes it an excellent choice for preventing air leakage and reducing energy loss. Spray foam insulation is also known for its excellent soundproofing qualities. In terms of installation, fiberglass mat tissue usually comes in large rolls or batts that need to be cut and fitted into place. It requires careful handling to ensure proper installation and may require the use of protective equipment, such as gloves and masks, as the fibers can cause skin and respiratory irritation. Spray foam insulation, on the other hand, is applied using specialized equipment that sprays the liquid foam onto the desired surface. It expands quickly, filling in any gaps or voids, and hardens within a short period of time. This makes it a more convenient option for insulating hard-to-reach areas or irregularly shaped spaces. When comparing the two, fiberglass mat tissue is generally more cost-effective, as it is less expensive to purchase and install compared to spray foam insulation. However, spray foam insulation provides better air sealing and can offer higher energy savings in the long run. In summary, fiberglass mat tissue and spray foam insulation have their own advantages and are suited for different insulation needs. Fiberglass mat tissue is a good option for thermal insulation, while spray foam insulation excels in air sealing and soundproofing. The choice between the two ultimately depends on factors such as budget, desired insulation performance, and the specific requirements of the project.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords