Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

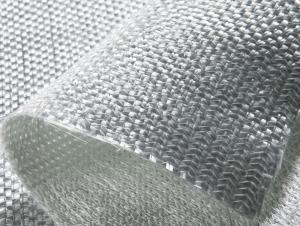

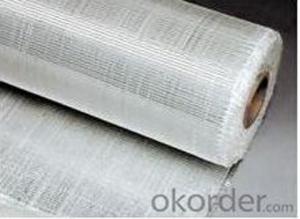

Structure of Fiberglass Multiaxial Fabric-UD Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of the Fiberglass Multiaxial Fabric-UD:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

Fiberglass Multiaxial Fabric-UD Images:

Unidirectional Specification:

Code | Total weight g/m2 | Weight of each layer, g/m2 | Width mm | ||||

0° | 90° | +45° | -45° | Chopping | |||

E-L300 | 350 | 300 | 50 | 200~2600 | |||

E-L350 | 400 | 350 | 50 | 200~2600 | |||

E-L400 | 450 | 400 | 50 | 200~2600 | |||

E-L450 | 500 | 450 | 50 | 200~2600 | |||

E-L500 | 550 | 500 | 50 | 200~2600 | |||

E-L600 | 650 | 600 | 50 | 200~2600 | |||

E-L650 | 700 | 650 | 50 | 200~2600 | |||

E-L900 | 930 | 880 | 50 | 200~2600 | |||

E-L700/200 | 950 | 700 | 50 | 200 | 200~2600 | ||

E-T200 | 200 | 200 | 200~2600 | ||||

E-T450 | 450 | 450 | 200~2600 | ||||

E-T500 | 500 | 500 | 200~2600 | ||||

E-TM300/300 | 600 | 300 | 300 | 200~2600 | |||

E-TM600/450 | 1050 | 600 | 450 | 200~2600 | |||

E-LM750/200 | 950 | 750 | 200 | 200~2600 | |||

FAQ of Unidirectional

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: What are the different weights available for fiberglass mat tissue?

- Various industries, including construction, automotive, and marine, utilize fiberglass mat tissue extensively. This versatile material is available in different weights or thicknesses to meet various applications and specifications. The weight of fiberglass mat tissue is typically measured in grams per square meter (gsm) or ounces per square yard (oz/yd²). Typically, the available weights for fiberglass mat tissue range from approximately 30 gsm (1 oz/yd²) to 150 gsm (5 oz/yd²) or higher. The weight of the tissue directly affects its strength, rigidity, and durability. For applications that require a high degree of flexibility and conformability, lightweight fiberglass mat tissue weighing around 30-50 gsm (1-1.5 oz/yd²) is commonly used. These lighter weight tissues are often employed in the production of laminates, reinforcing materials, and lightweight composites. Medium weight fiberglass mat tissue, typically falling within the range of 70 gsm (2 oz/yd²) to 100 gsm (3 oz/yd²), strikes a balance between flexibility and strength. It finds frequent use in applications such as roofing, insulation, and wall panels, where structural integrity and thermal insulation properties are of utmost importance. For applications that demand exceptional strength and rigidity, heavyweight fiberglass mat tissue weighing between 120 gsm (4 oz/yd²) and 150 gsm (5 oz/yd²) or more is ideal. This type of tissue is commonly employed in demanding applications like boat hulls, automotive body parts, and industrial equipment, where durability and resistance to impact and stress are critical. It is important to recognize that the availability of different weights of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the application. In certain cases, custom weights can be manufactured to meet unique project needs. In summary, fiberglass mat tissue is available in a range of weights to accommodate diverse applications. Selecting the appropriate weight is essential to ensuring optimal performance and long-term durability in various industries.

- Q: What is the fire rating of fiberglass mat tissue?

- The fire rating of fiberglass mat tissue differs based on its specific composition and the standards it has been tested against. Typically, fiberglass mat tissue is engineered to possess fire-resistant qualities, but the actual fire rating relies on variables like the tissue's thickness and any supplementary fire retardant coatings or treatments. To ascertain the fire rating of a particular fiberglass mat tissue product, it is advisable to refer to the manufacturer's specifications or test reports, as they offer the most precise and current information available.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Certifications and standards are necessary to guarantee the quality and appropriateness of fiberglass mat tissue for different purposes. The ASTM D 4601 standard is widely recognized and specifies the minimum requirements for glass fiber mats used in roofing and waterproofing systems. It covers various physical properties like weight, thickness, tensile strength, tear resistance, and water resistance. Apart from ASTM D 4601, fiberglass mat tissue may undergo testing based on its intended usage. For example, if it is used in the automotive industry, it may need to meet ISO 9001 or IATF 16949 standards, ensuring quality management systems and product consistency. Furthermore, fiberglass mat tissue used in construction or building materials should adhere to regulations set by organizations like the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards primarily focus on fire resistance, thermal insulation properties, and overall safety. Ultimately, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry it is used in. These standards are pivotal in ensuring the quality, performance, and safety of fiberglass mat tissue products.

- Q: How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a versatile reinforcement material that offers several advantages over other types of reinforcement materials. Firstly, it has excellent strength and stiffness properties, providing superior load-bearing capabilities compared to other materials. Secondly, fiberglass mat tissue is lightweight, making it easier to handle and install. Additionally, it is highly resistant to corrosion, chemicals, and moisture, ensuring long-term durability. Lastly, fiberglass mat tissue has excellent dimensional stability and is not prone to warping or shrinking, making it a reliable choice for various applications. Overall, its combination of strength, lightweight nature, durability, and dimensional stability sets fiberglass mat tissue apart from other reinforcement materials.

- Q: Does fiberglass mat tissue require any special handling or storage requirements?

- Fiberglass mat tissue necessitates specific care and storage measures. To begin with, it is imperative to handle fiberglass mat tissue delicately in order to prevent any harm or breakage. The tissue should be treated with gentleness and not pulled or dropped, as this may result in the separation or damage of the fibers. It is also advisable to wear gloves and protective clothing while handling fiberglass mat tissue to avoid any skin irritation or injuries. Regarding storage, it is crucial to keep fiberglass mat tissue in a clean and dry environment. Shielding it from moisture is of utmost importance, as water exposure can weaken the fibers and diminish its efficacy. Therefore, it is preferable to store fiberglass mat tissue in sealed, moisture-proof packaging or in a dry room with controlled humidity levels. Furthermore, fiberglass mat tissue should be kept away from direct sunlight and extreme temperatures. High temperatures can cause the resin in the tissue to cure prematurely, while excessive cold can make it brittle and more susceptible to damage. Hence, it is recommended to store fiberglass mat tissue in a cool and shaded area to maintain its quality and ensure its longevity. By adhering to these specialized handling and storage requirements, fiberglass mat tissue can be safeguarded and preserved in its optimal condition, ready for utilization in various industries such as construction, insulation, or automotive.

- Q: Does fiberglass mat tissue provide any acoustic insulation?

- Fiberglass mat tissue does provide some degree of acoustic insulation. Due to its fibrous structure, it can absorb sound waves and reduce their transmission through walls or other surfaces. However, it is important to note that the level of acoustic insulation provided by fiberglass mat tissue may vary depending on various factors such as thickness, density, and the specific application. In some cases, additional layers or thicker materials may be required to achieve optimal acoustic insulation.

- Q: What are the different color options available for fiberglass mat tissue?

- Various color options are offered for fiberglass mat tissue, catering to different preferences and applications. White, gray, black, and beige are among the commonly available colors. These color choices offer versatility in design and aesthetics, allowing users to select a color that enhances their individual project needs. Factors like UV resistance and desired visibility or camouflage levels can also influence the color selection. In conclusion, the availability of diverse color options for fiberglass mat tissue grants users the flexibility and customization opportunities necessary to achieve their desired results.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue plays a crucial role in determining its performance. Thicker fiberglass mat tissues generally provide better strength and durability compared to thinner ones. A thicker mat tissue allows for a higher resin-to-glass ratio, resulting in improved stiffness and toughness. This increased resin content enhances the overall structural integrity and mechanical properties of the fiberglass mat tissue. It also helps to minimize the risk of delamination and improves resistance to impact and fatigue. Moreover, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a higher density of fibers, which enhances the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to note that the specific application and requirements should be considered when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more expensive. Therefore, a balance must be struck between the desired performance characteristics and the practical considerations of weight, cost, and ease of installation.

- Q: What are the different methods of bonding fiberglass mat tissue to other materials?

- There are several methods of bonding fiberglass mat tissue to other materials, including mechanical bonding, chemical bonding, and thermal bonding. Mechanical bonding involves using adhesives or fasteners to physically attach the fiberglass mat tissue to the other material. Chemical bonding involves using a bonding agent or adhesive that chemically reacts with both the fiberglass mat tissue and the other material, creating a strong bond. Thermal bonding involves using heat to melt the fiberglass mat tissue and fuse it with the other material, creating a cohesive bond.

- Q: Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords