Fiberglass Mat Tissue Unidirectional Fabric 450gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

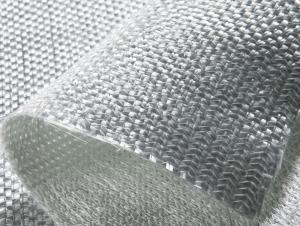

Structure of Fiberglass Multiaxial Fabric-UD Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.Main Features of the Fiberglass Multiaxial Fabric-UD:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.Fiberglass Multiaxial Fabric-UD Images:

Unidirectional Specification:

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ of Unidirectional

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Is fiberglass mat tissue easy to install?

- Yes, fiberglass mat tissue is relatively easy to install. It is a lightweight and flexible material that can be easily cut and shaped to fit any surface. It can be applied using various methods such as spraying, rolling, or brushing on adhesive. The tissue is also self-adhesive, which makes it even easier to install as it can easily stick to the desired surface. Additionally, fiberglass mat tissues are typically designed to be water-resistant and provide excellent insulation properties, making them a popular choice for a wide range of applications. Overall, with proper preparation and following the manufacturer's instructions, installing fiberglass mat tissue can be a straightforward and hassle-free process.

- Q: How does the fiber distribution of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is significantly influenced by the distribution of its fibers. The primary source of strength for fiberglass mat tissue is the inclusion of fibers within the material. These fibers act as reinforcement and aid in evenly distributing stress and load across the surface. The distribution of fibers in fiberglass mat tissue refers to their arrangement and orientation within the material. When fibers are evenly distributed, with a consistent arrangement and orientation, the strength of the fiberglass mat tissue is enhanced. This uniform distribution allows for efficient transfer of load from one fiber to another, resulting in improved overall strength. Conversely, an uneven or random distribution of fibers, where they are clumped together or oriented in various directions, compromises the strength of the fiberglass mat tissue. This uneven distribution can create areas of concentrated stress, leading to weak points and potential failure under load. Additionally, the strength of fiberglass mat tissue is also influenced by the length and density of the fibers. Longer fibers provide greater reinforcement and enhance the tensile strength of the material. Furthermore, a higher fiber density, meaning more fibers per unit area, increases the overall strength and performance of the fiberglass mat tissue. In conclusion, the strength of fiberglass mat tissue is directly impacted by the distribution of its fibers. A uniform and evenly distributed arrangement of fibers improves the material's strength by facilitating efficient load transfer. Conversely, an uneven or random distribution compromises the strength by creating stress concentrations and weak points. The fiber length and density also contribute to the overall strength of the fiberglass mat tissue.

- Q: Is fiberglass mat tissue compatible with different curing methods?

- Yes, fiberglass mat tissue is compatible with different curing methods. It can be cured using various methods, such as wet lay-up, resin infusion, and vacuum bagging. The mat tissue can be impregnated with different types of resins, including polyester, epoxy, and vinyl ester, allowing it to be used in a wide range of applications and cured using the appropriate method for each specific resin system.

- Q: Can fiberglass mat tissue be used for insulation in shopping malls?

- Indeed, insulation in shopping malls can incorporate the utilization of fiberglass mat tissue. This material is widely employed and proven to be efficient for thermal insulation owing to its low thermal conductivity and exceptional resistance to heat transfer. Moreover, fiberglass mat tissue possesses the advantage of being non-combustible, rendering it a secure choice for commercial structures such as shopping malls. Furthermore, its lightweight nature facilitates effortless installation, and its superb sound absorption properties contribute to establishing a pleasant and serene ambiance in the mall. All in all, fiberglass mat tissue emerges as an appropriate selection for insulation in shopping malls, ensuring energy efficiency and enhanced indoor comfort.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Yes, fiberglass mat tissue can be used for bridge construction. Fiberglass mat tissue is a versatile material that offers several advantages. It is lightweight yet strong, making it suitable for use in bridge construction where weight considerations are important. Additionally, fiberglass mat tissue is highly durable and resistant to corrosion, which is crucial for the longevity and maintenance of bridges. It can also be easily molded into various shapes, allowing for flexibility in bridge design. Moreover, fiberglass mat tissue has good impact resistance and excellent fatigue performance, ensuring the bridge's ability to withstand heavy loads and constant traffic. Overall, fiberglass mat tissue is a reliable and cost-effective material for bridge construction.

- Q: What are the different types of fiberglass mat tissue available?

- There are several different types of fiberglass mat tissues available, each with its own unique characteristics and applications. Some of the most common types include: 1. Chopped Strand Mat (CSM): This is the most basic and widely used type of fiberglass mat tissue. It consists of randomly oriented chopped strands of fiberglass held together with a binder. CSM is typically used in applications where strength and resilience are important, such as boat building and automotive parts manufacturing. 2. Continuous Filament Mat (CFM): Unlike CSM, CFM is made from continuous strands of fiberglass that are woven into a mat. This type of fiberglass mat tissue offers excellent tensile strength and dimensional stability, making it ideal for applications that require high strength and stiffness, such as aerospace components and wind turbine blades. 3. Surface Veil Mat: Surface veil mat is a very thin and lightweight type of fiberglass mat tissue that is used primarily for surface finishing and reinforcement. It is typically applied as a final layer in composite laminates to improve the surface smoothness and water resistance. 4. Stitched Mat: Stitched mat is made by interweaving continuous strands of fiberglass with a stitching thread. This construction provides increased strength and improved drapability, making it easier to conform to complex shapes. Stitched mat is commonly used in applications that require a combination of strength and flexibility, such as in the production of pipes and tanks. 5. Binderless Mat: Binderless mat is a specialty type of fiberglass mat tissue that does not contain any binders or resins. Instead, the fibers are mechanically bonded together using a needling process. This makes binderless mat highly resistant to chemical attack and suitable for use in corrosive environments, such as chemical storage tanks and pipes. These are just a few examples of the different types of fiberglass mat tissues available. The choice of which type to use depends on the specific requirements of the application, including strength, flexibility, surface finish, and resistance to various environmental factors.

- Q: What are the typical mechanical properties of fiberglass mat tissue?

- The typical mechanical properties of fiberglass mat tissue include high tensile strength, stiffness, and dimensional stability. Fiberglass mat tissue is known for its excellent resistance to breakage and deformation under stress, making it suitable for applications that require durability and structural integrity. It also exhibits good impact resistance, allowing it to withstand external forces without significant damage. Additionally, fiberglass mat tissue has a low coefficient of thermal expansion, meaning it is less prone to expanding or contracting with temperature changes, resulting in improved dimensional stability. These properties make fiberglass mat tissue a popular choice in various industries, such as construction, automotive, and aerospace, where strength and reliability are crucial factors.

- Q: What are the different grades of fiberglass mat tissue available?

- In the market, you can find various grades of fiberglass mat tissue. These grades differ in terms of their weight, thickness, and strength. The most popular grades include lightweight, medium-weight, and heavyweight fiberglass mat tissue. When it comes to lightweight fiberglass mat tissue, it is generally thinner and lighter compared to other grades. It is commonly used in situations where flexibility and easy handling are important. This grade is suitable for projects like laminating lightweight structures, making molds, and doing repairs. If you're looking for a versatile option that offers a balance between strength and flexibility, medium-weight fiberglass mat tissue is the way to go. It is widely used in boat building, automotive repairs, and general fiberglass reinforcement. This grade provides sufficient strength while still being manageable to work with. On the other hand, if you need superior strength and durability, heavyweight fiberglass mat tissue is the grade for you. It is the thickest and heaviest grade available in the market. This grade is perfect for applications that require high structural integrity, such as construction, aerospace, and marine industries. Apart from these standard grades, there may be variations and special grades available depending on the manufacturer and the specific requirements of your project. It is crucial to consult with a supplier or manufacturer to determine the most suitable grade of fiberglass mat tissue for your particular application.

- Q: Glass fiber cotton or ceramic fiber paper insulation?

- Glass fiber cotton bar, there are more air inside, the effect may be better

- Q: Can fiberglass mat tissue be used for automotive applications?

- Yes, fiberglass mat tissue can be used for automotive applications. Fiberglass mat tissue is a versatile material that is commonly used in the automotive industry for various purposes. It is often used as a reinforcement material in composite parts, such as bumpers, body panels, and interior components. The high strength and lightweight properties of fiberglass mat tissue make it an ideal choice for automotive applications, as it helps to enhance the overall performance and durability of the vehicle. Additionally, fiberglass mat tissue can also provide excellent sound insulation and vibration damping properties, which are crucial for improving the comfort and noise reduction in automobiles. Overall, fiberglass mat tissue is a reliable and widely used material in the automotive industry, contributing to the production of high-quality and efficient vehicles.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 450gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords