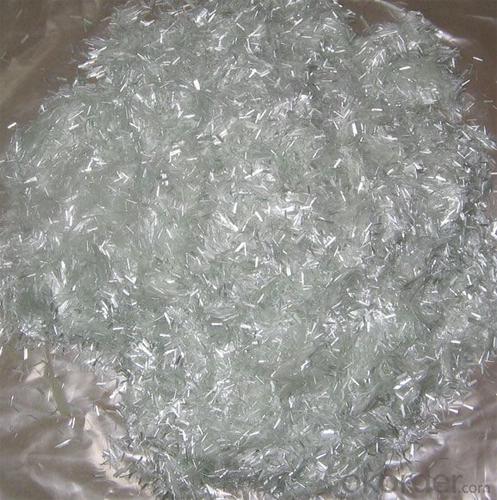

Fiberglass Mat Tissue E-Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

Chopped strand mat is a non-woven reinforced material. It is manufactured by spreading continuous filament roving of 50mm in length, distributed it at random uniformly held together with powder or emulsion binder.

Product Features:

Uniform thickness, softness and hardness good.

Good compatibility with resin, easy completely wet-out.

Fast and consistent wet-out speed in resins and good manufacturability.

Good mechanical properties, easy cutting.

Good cover mold, suitable for modeling complex shapes.

Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

No special requirements in the case of chopped strand mat should be placed in a dry, cool damp-proof place. It should always be remained in the original packaging before and after use. The best storage temperature is between15 ℃ to 35 ℃, relative humidity of 35% -65%

- Q: Can fiberglass mat tissue be used for soundproofing?

- Indeed, soundproofing can be achieved with the utilization of fiberglass mat tissue. Renowned for its remarkable sound absorption capabilities, fiberglass proves to be an exceptional choice. Whether employed as a mat or tissue, it effectively diminishes noise transmission by absorbing and attenuating sound waves. The porous composition of fiberglass enables it to capture and disperse sound energy, rendering it a perfect material for soundproofing purposes. Furthermore, fiberglass possesses the advantages of being lightweight, flexible, and straightforward to install, thus making it an exceedingly convenient option for soundproofing endeavors.

- Q: How does fiberglass mat tissue compare to other insulation materials?

- Fiberglass mat tissue is a highly effective insulation material that offers several advantages over other insulation materials. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which means it effectively prevents heat transfer and helps maintain a comfortable indoor temperature. This is particularly important in extreme climates where heat or cold can easily penetrate the building envelope. Additionally, fiberglass mat tissue is resistant to moisture, mold, and mildew, making it a durable and long-lasting insulation option. It does not absorb water, which helps to prevent the growth of mold and the degradation of the material over time. This is especially beneficial in humid environments or areas prone to moisture accumulation, such as basements or bathrooms. Furthermore, fiberglass mat tissue is non-combustible and has a high fire resistance rating. This makes it a safe choice for insulation, as it does not contribute to the spread of flames in case of a fire. It can also act as a barrier, preventing the fire from spreading to other areas of the building and offering occupants valuable time to evacuate. In terms of installation, fiberglass mat tissue is relatively easy to handle and install. It can be cut to fit any desired shape or size, allowing for flexibility during installation. It can also be used in various applications, including walls, floors, ceilings, and roofs, making it a versatile insulation material. Lastly, fiberglass mat tissue is an environmentally friendly option. It is made from recycled glass and sand, which helps reduce waste and conserve natural resources. It is also recyclable at the end of its lifespan, further minimizing its environmental impact. Overall, fiberglass mat tissue exhibits superior thermal insulation properties, durability, resistance to moisture and fire, ease of installation, and environmental sustainability, making it a highly favorable choice when compared to other insulation materials.

- Q: Can fiberglass mat tissue be used for insulation in cryogenic applications?

- Indeed, insulation in cryogenic applications can be accomplished using fiberglass mat tissue. Renowned for its exceptional thermal insulation properties, fiberglass is a versatile substance. Its capability to diminish heat transfer is heightened due to its low thermal conductivity. Consequently, it is remarkably suitable for cryogenic applications that necessitate the maintenance of exceedingly low temperatures. Furthermore, fiberglass possesses non-combustible qualities and does not absorb moisture, rendering it the perfect choice for cryogenic environments. By implementing it as an insulation layer, fiberglass can effectively impede heat transfer and sustain the desired low temperatures in cryogenic storage tanks, pipes, and other related equipment.

- Q: Is fiberglass mat tissue biodegradable?

- Fiberglass mat tissue does not possess biodegradable properties. It is an artificial substance composed of delicate glass fibers intricately interwoven to form a resilient and long-lasting material. These fibers do not undergo natural decomposition, rendering fiberglass mat tissue to be non-biodegradable.

- Q: Can fiberglass mat tissue be used for insulating windows?

- No, fiberglass mat tissue is not suitable for insulating windows. It is primarily used for reinforcing and strengthening surfaces, such as in the construction industry, and is not designed to provide thermal insulation.

- Q: What is the flexibility of fiberglass mat tissue?

- The flexibility of fiberglass mat tissue refers to its ability to bend, conform, or mold to different shapes or surfaces without breaking or losing its structural integrity. The unique properties of fiberglass, such as its high strength-to-weight ratio and dimensional stability, allow the mat tissue to be flexible while still maintaining its strength and durability. This flexibility makes fiberglass mat tissue a versatile material that can be used in a wide range of applications, including automotive parts, construction materials, and boat manufacturing. Additionally, the flexibility of fiberglass mat tissue enables it to be easily cut, shaped, or layered to meet specific design requirements or fit into complex or curved surfaces.

- Q: What is the weathering resistance of fiberglass mat tissue?

- The weathering resistance of fiberglass mat tissue is generally considered to be high. Fiberglass mat tissue is made from a combination of fiberglass strands and a binder material, such as polyester or acrylic. This combination creates a strong and durable material that is resistant to various weathering factors, including exposure to sunlight, moisture, and temperature fluctuations. The fiberglass strands in the mat tissue provide excellent mechanical strength, preventing the material from breaking down under external stress or pressure. This strength helps the mat tissue withstand the impact of wind, rain, and other weather elements without significant damage. Additionally, the binder material used in the manufacturing process of fiberglass mat tissue is often formulated to be resistant to UV radiation. This UV resistance helps to protect the material from degradation and color fading caused by prolonged exposure to sunlight. It also helps to maintain the structural integrity and strength of the mat tissue over time. Furthermore, fiberglass mat tissue is also resistant to moisture and water absorption. This resistance prevents the material from becoming weakened or deteriorated when exposed to rain, humidity, or other moisture sources. As a result, the mat tissue remains intact and retains its performance properties even in wet or humid conditions. Overall, the weathering resistance of fiberglass mat tissue is considered to be excellent, making it a popular choice for various applications where durability and longevity in outdoor environments are required.

- Q: Can fiberglass mat tissue be used for repairing fiberglass tanks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass tanks. It is commonly used as a reinforcement material to strengthen and repair damaged areas in fiberglass tanks due to its high tensile strength and compatibility with fiberglass resin.

- Q: Does fiberglass mat tissue require any surface preparation before application?

- Surface preparation is typically necessary before applying fiberglass mat tissue. This ensures proper adhesion and bonding between the tissue and the surface it will be applied to. The exact preparation required may vary depending on the application and surface condition. However, there are common steps such as cleaning the surface to remove dirt, grease, and contaminants, roughening the surface through sanding, and applying a primer or bonding agent if needed. Following the manufacturer's instructions is crucial for achieving the best results and optimal performance.

- Q: Can fiberglass mat tissue be used for insulation in power generation facilities?

- Yes, fiberglass mat tissue can be used for insulation in power generation facilities.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords