Fiberglass Mat Tissue C-Glass Chopped Strand Mat Fiberglass Raw Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 600000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form(or other binder in emulsion form). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP molding, such as: various sheets and panels, boat hulls, cooling towers, corrosion resistant, vehicles etc.

Product Function

Fiberglass chopped strand mat is chopped using the “E” chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturated polyester resins.

Packaging & Delivery of C-glass Chopped Strand Mat

Packaging Detail: | cartons and pallets |

Delivery Detail: | within two weeks |

Main Features of C-glass Chopped Strand Mat

C-glass fiber chopped strand mat:

1. good wet-out

2. evenly distribution of fiber and binder

3. high mechanical strength etc.

Specification C-glass Chopped Strand Mat

We could provide E-Glass Powder Chopped Strand Mat and E-Glass Emulsion Chopped Strand Mat.

Specs | Roll length(m) | Width(mm) | Roll weight(kg) | Compatible Resin |

EMC225 | 1040mm | 144 | 30 | UP VE |

EMC300 | 1040mm | 96 | 30 | UP VE |

EMC380 | 1040mm | 80 | 30 | UP VE |

EMC450 | 2080mm | 64 | 60 | UP VE |

EMC600 | 2080mm | 48 | 60 | UP VE |

EMC900 | 2080mm | 32 | 60 | UP VE |

The products is raw material to produce FRP products.

Binder type: Emulsion or Power

Packing: by carton or by pallet, or as your requested

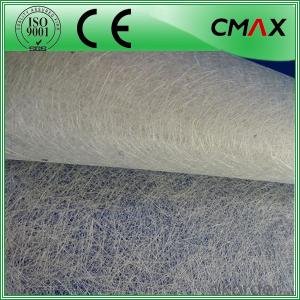

Pictures of C-glass Chopped Strand Mat

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue typically has low air permeability. The tight weave and construction of the fiberglass strands used in the mat tissue make it less porous, allowing very little air to pass through it. This characteristic makes fiberglass mat tissue a suitable material for applications where air permeability needs to be minimized, such as in insulation or filtration systems. By restricting the passage of air, fiberglass mat tissue helps to enhance thermal insulation properties and improve filtration efficiency.

- Q: Can fiberglass mat tissue be used for boat building?

- Yes, fiberglass mat tissue can be used for boat building. Fiberglass mat tissue is a lightweight and versatile material that is commonly used in the construction of boats. It is made up of thin strands of fiberglass woven together to form a mat-like structure. This material is known for its high strength-to-weight ratio, making it an ideal choice for boat builders. Fiberglass mat tissue is often used in boat building to reinforce the structure and provide added strength. It can be applied to the hull, deck, or other parts of the boat to enhance its durability and resistance to impact. Additionally, it can be used to create a smooth and even surface, which is important for achieving a professional finish. One of the advantages of using fiberglass mat tissue in boat building is its ease of application. It can be easily cut to size and molded to fit the desired shape, allowing for flexibility and customization. It can also be easily layered with other materials, such as epoxy resin, to create a strong and reliable composite. Furthermore, fiberglass mat tissue is highly resistant to water and corrosion, making it suitable for marine environments. It is also known for its excellent thermal and electrical insulation properties, which are beneficial for boat builders. In conclusion, fiberglass mat tissue can indeed be used for boat building. Its lightweight, high strength, and resistance to water and corrosion make it a reliable and popular choice among boat builders.

- Q: What are the applications of fiberglass mat tissue?

- Fiberglass mat tissue is commonly used in various applications, including but not limited to, the construction industry, automotive manufacturing, and the production of composite materials. It is used as a reinforcement material in the construction of walls, roofs, and floors, providing strength and durability. In the automotive industry, fiberglass mat tissue is used for sound insulation and as a reinforcement material in the production of car parts. Additionally, it is widely utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics, due to its high strength-to-weight ratio and excellent corrosion resistance.

- Q: Is fiberglass mat tissue suitable for insulation in educational facilities?

- Yes, fiberglass mat tissue is suitable for insulation in educational facilities. Fiberglass mat tissue is commonly used in insulation applications due to its excellent thermal insulation properties. It is a lightweight and cost-effective material that can effectively insulate buildings, including educational facilities, against heat loss or gain. Fiberglass mat tissue is also known for its fire-resistant properties, which is an important aspect to consider in any building, especially in educational facilities where the safety of students and staff is a top priority. Additionally, fiberglass mat tissue is easy to install and does not require extensive maintenance, making it a convenient choice for insulation in educational facilities.

- Q: What is the flexibility of fiberglass mat tissue?

- Fiberglass mat tissue possesses a remarkable quality known as flexibility, which grants it the capability to bend, conform, or shape itself to various forms or surfaces without succumbing to breakage or compromising its structural integrity. The distinct characteristics of fiberglass, such as its exceptional strength-to-weight ratio and dimensional stability, allow the mat tissue to retain its flexibility while upholding its robustness and longevity. This adaptability endows fiberglass mat tissue with versatility, rendering it suitable for an extensive array of applications spanning from automotive components and construction materials to boat manufacturing. Furthermore, the flexibility of fiberglass mat tissue facilitates effortless cutting, shaping, or layering to meet specific design specifications or seamlessly integrate into intricate or curved surfaces.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- When considering soundproofing, fiberglass mat tissue offers potential benefits but its effectiveness will vary based on specific needs and desired soundproofing levels. Fiberglass mat tissue is a versatile and lightweight material that effectively absorbs and dampens sound waves. It possesses favorable acoustic properties and can aid in reducing noise transmission, making it a viable choice for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not deliver adequate soundproofing, particularly in environments with high levels of noise. To achieve optimal results, it is advisable to combine it with other soundproofing materials like acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Furthermore, the thickness and density of the fiberglass mat tissue can impact its sound absorption properties. Generally, thicker and denser mats are more effective in attenuating sound waves, but they may also present challenges in terms of flexibility and installation. In summary, while fiberglass mat tissue can contribute to soundproofing endeavors, its suitability depends on specific requirements, desired soundproofing levels, and the incorporation of additional materials. It is advisable to consult a soundproofing expert or conduct comprehensive research on the particular application to determine the most suitable solution for achieving effective soundproofing.

- Q: What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The expected lifespan of fiberglass mat tissue in cryogenic applications can vary depending on various factors such as the specific temperature, exposure time, and the quality of the material. However, in general, fiberglass mat tissue is known for its durability and resistance to extreme temperatures, making it suitable for long-term use in cryogenic applications. With proper installation and maintenance, it can potentially last for several years or even decades in such environments.

- Q: What is the maximum temperature that fiberglass mat tissue can withstand?

- The maximum temperature that fiberglass mat tissue can typically withstand is around 600-700 degrees Celsius.

- Q: Is fiberglass mat tissue resistant to corrosion?

- Indeed, corrosion is not a concern for fiberglass mat tissue as it is comprised of non-metallic elements like glass fibers, unlike metals which are susceptible to rust and corrosion. This quality renders fiberglass mat tissue highly suitable for various purposes that demand resistance against corrosion, such as reinforcing concrete structures within the construction sector or for boat building in the marine industry. Furthermore, fiberglass mat tissue exhibits resistance towards chemicals, moisture, UV rays, and extreme temperatures, thereby augmenting its strength and longevity.

- Q: What are the different methods of bonding fiberglass mat tissue to other materials?

- There are several methods of bonding fiberglass mat tissue to other materials, each with its own advantages and considerations. Some of the common methods include: 1. Mechanical Bonding: This method involves physically interlocking the fiberglass mat tissue with the other material. It can be achieved through techniques such as stitching, stapling, or using mechanical fasteners like screws or nails. Mechanical bonding provides a strong and durable connection, but it may require additional hardware and can be time-consuming. 2. Adhesive Bonding: Adhesive bonding is a popular method that uses adhesives or glue to join the fiberglass mat tissue with the other material. This method offers flexibility, as there are various types of adhesives available for different applications. It is important to choose an adhesive that is compatible with both the fiberglass mat tissue and the other material. Proper surface preparation and application techniques are crucial for achieving a strong bond. 3. Resin Infusion: Resin infusion is a process where a liquid resin is infused into the fiberglass mat tissue and other materials, creating a strong bond when cured. This method is commonly used in manufacturing composite products, as it allows for a seamless and uniform bond. Vacuum bagging or resin infusion techniques are typically employed to ensure proper resin distribution and consolidation. 4. Thermal Bonding: Thermal bonding involves the use of heat to bond the fiberglass mat tissue to another material. This method is particularly suitable for thermoplastic materials, as they can be softened and fused together with heat. Techniques such as heat welding or ultrasonic welding are commonly used for thermal bonding. It is important to ensure that the heat does not damage or degrade the fiberglass mat tissue during the bonding process. 5. Fusion Bonding: Fusion bonding is a method where the fiberglass mat tissue and the other material are heated to a molten state and then brought into contact to form a bond. This technique is commonly used in the manufacturing of thermosetting plastics or joining thermoplastic materials. Fusion bonding can provide a strong and seamless bond, but it requires careful control of temperature and pressure to ensure proper bonding without causing damage. In summary, the different methods of bonding fiberglass mat tissue to other materials include mechanical bonding, adhesive bonding, resin infusion, thermal bonding, and fusion bonding. The choice of bonding method depends on factors such as the materials being bonded, the desired strength and durability, and the specific application requirements.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Mat Tissue C-Glass Chopped Strand Mat Fiberglass Raw Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 600000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords