Glass Fiber Battery Separator Mat

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Battery separator fiberglass mat is mainly used lead-acid battery separator substrate, with its separator made of composite with excellent mechanical strength and resistance to vibration performance, strong battery starting capability with the separator assembly, long life.

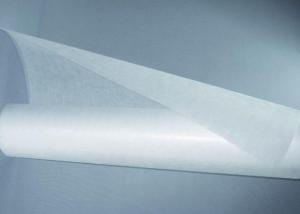

A smooth surface, uniform thickness

2, suction ability, good acid resistance, moderate stiffness

3, less content and impurity content of potassium permanganate reducing substance

3.Application

Technical parameters:

Product Code | Thickness(mm) | Chlorine content(%) | Iron content(%) | Potassium permanganate restore content(ml/g) |

S-GB-0.3 | 0.3±0.03 | ≤0.003 | ≤0.005 | ≤15 |

S-GB-0.4 | 0.4±0.03 | ≤0.003 | ≤0.005 | ≤15 |

S-GB-0.5 | 0.5±0.04 | ≤0.003 | ≤0.005 | ≤15 |

S-GB-0.6 | 0.6±0.04 | ≤0.003 | ≤0.005 | ≤15 |

S-GB-0.8 | 0.8±0.05 | ≤0.003 | ≤0.005 | ≤15 |

5.FAQ

According to customer requirements, special specifications are also available.

- Q: How does the weight of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is significantly affected by its weight. The weight of the tissue indicates the amount of glass fibers per unit area. Generally, a higher weight indicates a greater concentration of fibers, which results in improved strength and durability. To begin with, a heavier fiberglass mat tissue provides better tensile strength. The increased number of fibers in the tissue enables it to withstand higher levels of stress and strain without breaking or tearing. This makes it ideal for applications that require a high load-bearing capacity, such as structural components in the construction or automotive industries. Additionally, the weight of the tissue also impacts its stiffness and rigidity. A heavier mat tissue offers better dimensional stability, meaning it will maintain its shape and form even when subjected to external forces. This is crucial in applications where the material needs to retain its structural integrity, such as in boat hulls or wind turbine blades. Moreover, the weight of the fiberglass mat tissue affects its thermal and acoustic insulation properties. A higher weight is usually associated with better insulation capabilities, as the increased fiber density enhances the material's ability to trap air and reduce heat transfer or sound transmission. This makes it suitable for applications that require effective insulation, such as in buildings or industrial equipment. Finally, the weight of the fiberglass mat tissue can impact how easily it can be handled and installed. A lighter tissue may be more flexible and easier to manipulate, making it simpler to fit into complex shapes or tight spaces. Conversely, a heavier tissue might require additional support or equipment during installation. In conclusion, the weight of fiberglass mat tissue has a direct influence on its performance characteristics, including tensile strength, rigidity, insulation properties, and ease of handling. Therefore, it is crucial to consider the intended application and the desired performance requirements when selecting the appropriate weight of fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for making insulation blankets?

- Yes, fiberglass mat tissue can be used for making insulation blankets. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in insulation applications. It offers excellent thermal insulation properties, as well as resistance to fire, moisture, and chemicals. Additionally, fiberglass mat tissue is easy to handle and install, making it an ideal choice for creating insulation blankets that can be used in various industries, such as construction, automotive, and aerospace.

- Q: How is fiberglass mat tissue made?

- Fiberglass mat tissue is made through a process called wet-laid process, which involves several steps. First, glass fibers are created by melting and extruding glass through small holes to form continuous filaments. These filaments are then coated with a sizing agent to improve their handling properties and strengthen the final product. Next, the glass fibers are chopped into short lengths to create a fiber mat. This is usually done using a knife or a rotary chopper. The chopped fibers are then collected and formed into a thin layer on a moving conveyor belt. In parallel to this, a binder solution is prepared by mixing a synthetic resin with water. This solution is then sprayed onto the fiber mat to wet and bind the fibers together. The amount of binder used determines the strength and flexibility of the final product. To ensure uniform distribution of the binder and proper consolidation of the mat, it passes through a series of rollers. These rollers apply pressure to remove excess water, squeeze the fibers together, and promote bonding between the fibers. Once the mat is consolidated and the desired thickness is achieved, it is dried in an oven or through hot air currents. This removes any remaining moisture and cures the binder, transforming it into a solid resin. After drying, the fiberglass mat tissue is wound into rolls for storage or further processing. It can be used as a reinforcing material in various industries, such as construction, automotive, and aerospace, due to its excellent strength, corrosion resistance, and thermal insulation properties.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Certainly! Fiberglass mat tissue is an excellent choice for fixing fiberglass shower stalls. It is a flexible material that is widely utilized for reinforcing and mending various fiberglass structures, such as shower stalls. Its purpose is to enhance the strength and resilience of the repaired section, guaranteeing a durable and dependable solution. By pairing fiberglass mat tissue with compatible fiberglass resin, one can effectively mend cracks, holes, and other impairments in fiberglass shower stalls. Nevertheless, it is vital to diligently adhere to the instructions and recommendations provided by the manufacturer to achieve optimal outcomes in terms of application and curing.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Indeed, some degree of UV resistance is typically offered by fiberglass mat tissue. Comprised of glass fibers embedded in a resin matrix, this material provides a certain level of safeguard against UV radiation emitted by the sun. Nevertheless, it should be emphasized that the extent of UV resistance may differ based on the precise composition and manufacturing procedure of the fiberglass mat tissue. Furthermore, extended exposure to UV radiation can still result in gradual deterioration. Therefore, it is advisable to implement suitable measures, such as employing UV-resistant coatings or finishes, to augment the longevity and resilience of fiberglass mat tissue when utilized outdoors.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- No, fiberglass mat tissue is not suitable for insulation in pharmaceutical storage areas. This material may release particles or fibers that can contaminate the pharmaceutical products, which could compromise their quality and safety. It's essential to use insulation materials that are specifically designed and approved for pharmaceutical storage areas to ensure optimal conditions and adherence to regulatory standards.

- Q: What are the different reinforcement patterns available for fiberglass mat tissue?

- Some different reinforcement patterns available for fiberglass mat tissue include random pattern, grid pattern, and diamond pattern. Each pattern offers different levels of strength and durability depending on the specific application and requirements.

- Q: Does fiberglass mat tissue provide any acoustic insulation?

- Fiberglass mat tissue does provide some degree of acoustic insulation. Due to its fibrous structure, it can absorb sound waves and reduce their transmission through walls or other surfaces. However, it is important to note that the level of acoustic insulation provided by fiberglass mat tissue may vary depending on various factors such as thickness, density, and the specific application. In some cases, additional layers or thicker materials may be required to achieve optimal acoustic insulation.

- Q: Is the Teflon gasket filled with fiberglass or graphite?

- PTFE itself has the effect of self lubrication, you can ask the production of PTFE can add these, should not be able to! Vespel can add graphite to increase self lubrication

- Q: How is fiberglass mat tissue used in the automotive industry?

- The automotive industry relies heavily on fiberglass mat tissue for various purposes. This versatile material offers numerous advantages, making it an ideal choice for multiple applications. Reinforcing composite materials is one of the primary uses of fiberglass mat tissue in the automotive industry. It is commonly employed as a reinforcement layer during the production of car panels, hoods, roofs, and doors. By enhancing the structural integrity of these components, the fiberglass mat tissue makes them more durable and resistant to impact and external forces. This reinforcement property contributes to the overall safety of the vehicle. Furthermore, fiberglass mat tissue is also utilized for sound insulation in the automotive industry. This material possesses excellent sound absorption properties, effectively reducing noise and vibrations within the vehicle. By incorporating fiberglass mat tissue in areas like the floor, doors, and roof, automakers can significantly improve the overall acoustic comfort of the vehicle, providing a quieter and more enjoyable driving experience. Moreover, fiberglass mat tissue finds application in thermal insulation within the automotive industry. Acting as a barrier against heat transfer, this material helps regulate the temperature inside the vehicle. By incorporating fiberglass mat tissue in areas such as the engine compartment, exhaust system, and undercarriage, automakers can insulate the vehicle from excessive heat, preventing overheating and ensuring optimal performance. In conclusion, fiberglass mat tissue is extensively used in the automotive industry for reinforcement, sound insulation, and thermal insulation purposes. Its versatility makes it an indispensable material in vehicle manufacturing, contributing to improved safety, comfort, and performance.

Send your message to us

Glass Fiber Battery Separator Mat

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords