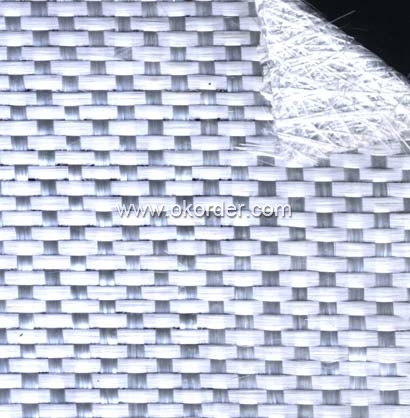

Fiberglass Fabrics Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Fiberglass Stitch Combo Mat

Name: | E-Glass Stitch Combo Mats |

Lead Time: | 20 days for 1 x 20FCL |

MinOrder: | One Pallet |

Package: | Plastic Bag, Carton and Pallet |

Characteristic of Fiberglass Stitch Combo Mat

The special product construction where 0°,90°rovings are parallel aligned without crossing facilities resin impregnation in the layers of chopped strands, resulting in higher productivity and reduced consumption of resins.

The multi-layer structure delivers increased area weight and simplifies the manufacturing process of the composite products, resulting in improve molding productivity and reduced cost.

The composite products feature multi-directional and balanced mechanical properties.

Package of Fiberglass Stitch Combo Mat

Each stitch combo mat is wounded onto a paper tube which has an inside diameter of 73mm, and the roll has a diameter of 260mm. The roll is wrapped up with plastic film, and then packed in a cardboard box or wrapped up with kraft paper. The rolls are to be horizontally placed. For transporation the rolls can be loaded into a container directly or on pallets.

Storage of Fiberglass Stitch Combo Mat

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respectively.

Standard:ISO 9001

- Q: Is fiberglass fabric resistant to termites?

- No, fiberglass fabric is not resistant to termites. Termites are known to feed on organic materials such as wood, paper, and fabric, and fiberglass fabric is not exempt from their feeding habits. While fiberglass fabric may not provide a suitable food source for termites, they can still cause damage to the fabric by chewing through it or using it as a pathway to reach other materials. Therefore, it is important to take appropriate measures to protect fiberglass fabric from termite infestation, such as using termite barriers, regular inspections, and treating the surrounding area for termites if necessary.

- Q: Is fiberglass fabric resistant to chemical degradation?

- Fiberglass fabric is known for its excellent resistance to chemical degradation. Due to its composition of glass fibers, which are impervious to most chemicals, it is highly resistant to the effects of various corrosive substances. Fiberglass fabric can withstand exposure to acids, alkalis, solvents, oils, and other chemicals commonly found in industrial environments without significant degradation. This makes it a preferred choice for applications where chemical resistance is of utmost importance, such as in the manufacturing of chemical storage tanks, pipes, and linings. Additionally, fiberglass fabric's resistance to chemical degradation also contributes to its durability and longevity, making it a reliable material for a wide range of industrial and commercial applications.

- Q: How is fiberglass fabric used in the manufacturing of sports equipment?

- Fiberglass fabric is commonly used in the manufacturing of sports equipment due to its unique properties and advantages it offers. One of the main uses of fiberglass fabric in sports equipment is for reinforcement purposes. The fabric is often layered and combined with resin to create a strong and durable composite material that is lightweight yet sturdy. In the production of sports equipment such as tennis rackets, golf clubs, and hockey sticks, fiberglass fabric is used to enhance the strength and stiffness of the product. The fabric is layered and bonded with other materials, such as carbon fiber, to create a composite structure that has excellent flexural strength and resistance to impact. This allows athletes to achieve greater power and control during their performance. Additionally, fiberglass fabric is also used in the manufacturing of protective gear for various sports. Helmets, shin guards, and body armor often incorporate fiberglass fabric due to its ability to absorb and distribute impact energy. The fabric's high tensile strength and resistance to tearing make it an ideal material for ensuring the safety of athletes during high-contact sports. Furthermore, fiberglass fabric is also employed in the production of sports equipment that requires waterproof or weather-resistant properties. For example, in the manufacturing of sailboards, canoes, and kayaks, the fabric is used to provide a protective layer that prevents water penetration. This helps to improve the durability and longevity of the equipment, enabling athletes to use them in various weather conditions without compromising their performance. In summary, fiberglass fabric plays a crucial role in the manufacturing of sports equipment by providing reinforcement, enhancing strength and durability, ensuring athlete safety, and enabling weather resistance. Its versatile properties make it an essential component in the production of a wide range of sports gear, contributing to better performance, protection, and overall enjoyment for athletes around the world.

- Q: How is fiberglass fabric used in the automotive industry?

- Fiberglass fabric is widely used in the automotive industry for various applications due to its unique properties. One of the main uses of fiberglass fabric in this industry is for manufacturing car parts such as body panels, hoods, and spoilers. Fiberglass fabric is chosen for these applications because it is lightweight, strong, and durable. This material offers excellent strength-to-weight ratio, which means it can provide high strength to the car parts without adding excessive weight. This is crucial for improving fuel efficiency and overall performance of the vehicle. Moreover, fiberglass fabric is also used in the automotive industry for insulation purposes. It is commonly used to insulate engine components, such as exhaust systems and heat shields, to protect surrounding parts from excessive heat. The high temperature resistance of fiberglass fabric makes it an ideal choice for these applications. In addition, fiberglass fabric is utilized in the manufacturing of automotive interiors. It is commonly used for upholstery, door panels, headliners, and trunk liners. The fabric offers excellent flexibility, allowing it to conform to different shapes and contours of the car interior. Furthermore, it is resistant to stains, chemicals, and fading, ensuring a long-lasting and aesthetically pleasing interior finish. Furthermore, fiberglass fabric is also used for reinforcement purposes in the automotive industry. It is often applied as a layer in the production of composite materials used for making car parts. By combining fiberglass fabric with resins or other materials, manufacturers can create strong and rigid components that are resistant to impact, vibrations, and other external forces. Overall, fiberglass fabric plays a vital role in the automotive industry by providing lightweight, durable, and heat-resistant solutions for various applications. Its versatility and exceptional properties make it an ideal material for manufacturing car parts, insulation, interiors, and reinforcement, contributing to the efficiency, safety, and overall quality of vehicles.

- Q: How is fiberglass fabric used in the insulation industry?

- Due to its exceptional thermal and acoustic insulation properties, fiberglass fabric finds extensive use in the insulation industry. It is a popular choice for insulating materials in numerous applications, including residential and commercial buildings, automotive, aerospace, and industrial equipment. In the construction industry, fiberglass fabric plays a vital role in insulation. It is commonly installed in walls, floors, and ceilings to enhance energy efficiency, reduce heating and cooling expenses by limiting heat transfer. Acting as a barrier, it prevents the flow of heat between different areas of a building. Moreover, its ability to resist moisture absorption helps prevent the growth of mold and mildew, ensuring a healthier indoor environment. Fiberglass fabric is also employed in the insulation of pipes, ducts, and HVAC systems. This usage helps maintain desired temperatures and prevents heat loss or gain during the transportation of liquids or air. Consequently, it ensures efficient operation and reduces energy consumption. Additionally, fiberglass fabric finds utilization in vehicle and aircraft insulation. It minimizes the transfer of heat and noise from the engine or external environment, providing passengers with a comfortable and quiet interior. Its lightweight and flexible nature make it ideal for these applications, as it can be easily molded and installed in complex shapes and tight spaces. In industrial settings, fiberglass fabric is used to insulate equipment such as boilers, furnaces, ovens, and tanks. By retaining heat, it facilitates efficient operation and minimizes energy loss. Furthermore, its fire-resistant properties are crucial for industries dealing with high temperatures and potential fire hazards. In summary, fiberglass fabric is a highly versatile and durable material with excellent insulation properties. Its thermal and acoustic insulation capabilities, moisture resistance, and ability to withstand high temperatures make it a preferred choice for various applications. Consequently, it contributes to energy efficiency, environmental sustainability, and improved comfort.

- Q: How is fiberglass fabric used in the production of insulation papers?

- Fiberglass fabric is commonly used in the production of insulation papers due to its excellent thermal properties and durability. The fabric is usually made from fine strands of glass fibers that are woven together to form a strong and flexible material. In the production of insulation papers, fiberglass fabric is often used as a reinforcement layer. It is placed between layers of paper or other insulating materials to provide added strength and stability. The fabric helps to prevent tearing or ripping of the insulation papers, ensuring their longevity and effectiveness. Moreover, fiberglass fabric is also highly resistant to heat, making it an ideal choice for insulation applications. It can withstand high temperatures without melting or degrading, allowing it to effectively retain and reflect heat within the insulation system. This property is crucial in preventing heat loss or gain, leading to energy efficiency and cost savings. Furthermore, the use of fiberglass fabric in insulation papers enhances their fire resistance capabilities. Fiberglass is inherently non-combustible and does not contribute to the spread of flames. When incorporated into insulation papers, it acts as a barrier against fire, helping to contain and limit its spread. Overall, fiberglass fabric plays a vital role in the production of insulation papers by providing strength, thermal insulation, and fire resistance. Its use ensures that the insulation materials are durable, energy-efficient, and safe, making it a preferred choice in various industries such as construction, automotive, and aerospace.

- Q: What are the different thickness options for fiberglass fabric rolls?

- There is a variety of thickness options for fiberglass fabric rolls to accommodate different applications and needs. Fiberglass fabric is typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The range of common thickness options for fiberglass fabric rolls is from 4 oz/yd² (135 g/m²) to 10 oz/yd² (340 g/m²). These options are suitable for a wide range of general-purpose applications, including reinforcing composite materials, boat building, automotive repairs, and insulation. For lighter applications, thinner fiberglass fabric rolls are available, typically ranging from 1 oz/yd² (34 g/m²) to 3 oz/yd² (102 g/m²). These lightweight options are commonly used in industries where weight is a concern, such as aerospace, model-making, and hobbyist projects. On the other hand, thicker fiberglass fabric rolls are available for heavy-duty applications that require greater strength and durability. These options typically range from 12 oz/yd² (408 g/m²) to 30 oz/yd² (1017 g/m²) or higher. They are commonly used in industrial settings, such as reinforcing concrete, manufacturing pipes, tanks, and other structural components. It's important to note that the specific thickness options may vary depending on the manufacturer and supplier. Some manufacturers may also offer custom thickness options to meet specific project requirements. Therefore, it's advisable to consult with the supplier or manufacturer to determine the available thickness options for fiberglass fabric rolls.

- Q: Can fiberglass fabric be used for insulation in construction projects?

- Yes, fiberglass fabric can be used for insulation in construction projects. Fiberglass fabric is made from woven glass fibers, which have excellent thermal insulation properties. It is commonly used as an insulation material in walls, roofs, and floors to prevent heat transfer and improve energy efficiency in buildings. The fabric is lightweight, flexible, and easy to install, making it a popular choice for construction projects. Additionally, fiberglass fabric is resistant to fire, moisture, and chemicals, making it a durable and long-lasting insulation material.

- Q: How does fiberglass fabric perform in terms of breathability?

- Known for its exceptional breathability, fiberglass fabric is highly regarded due to its woven structure that enables air to circulate freely. This feature sets it apart from other materials as it allows moisture and condensation to escape, thus preventing the accumulation of mold and mildew. Moreover, the breathability of fiberglass fabric ensures comfort for individuals by dissipating heat and keeping the body cool and dry. Consequently, this key characteristic has resulted in the widespread utilization of fiberglass fabric across numerous industries and applications.

- Q: Can fiberglass fabric be used for flags?

- Yes, fiberglass fabric can be used for flags. Fiberglass fabric is known for its durability, strength, and resistance to weathering, making it a suitable material for outdoor applications like flags. It is lightweight, yet tear-resistant, allowing flags made from fiberglass fabric to withstand strong winds and harsh weather conditions. Additionally, fiberglass fabric can be easily printed on, allowing for vibrant and long-lasting flag designs.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Fabrics Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords