High Quality Fiberglass Fabrics - E Glass Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

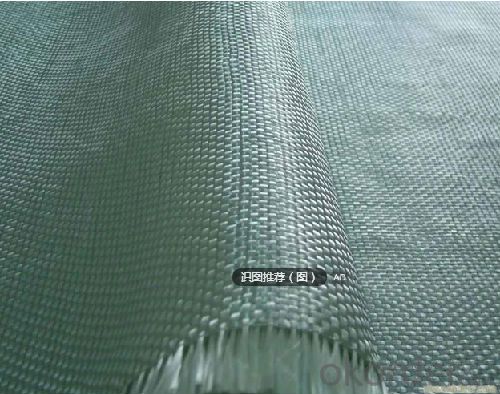

E Glass Fiber Fabrics are bidirectional fabric made by interweaving direct rovings.

E Glass Fiber Fabrics are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E Glass Fiber Fabrics are a high performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Product Features:

● Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

● Densely aligned fibers, resulting in high dimensional stability and making handling easy

● Good moldability, fast and complete wet out in resins, resulting in high productivity

● Good mechanical properties and high strength of parts

Product Specifications:

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Can fiberglass fabric be used for reinforcement in 3D printing?

- Yes, fiberglass fabric can be used for reinforcement in 3D printing. Fiberglass fabric is a strong and lightweight material that can provide additional structural support to 3D printed objects. It can be used to reinforce certain areas of a print, such as corners or joints, to prevent cracking or breaking. By adding layers of fiberglass fabric within the 3D printed object, the overall strength and durability can be significantly improved. However, it is important to note that using fiberglass fabric in 3D printing may require specialized equipment and techniques to ensure proper adhesion and integration with the printed material.

- Q: How does fiberglass fabric perform in shear strength?

- Fiberglass fabric has excellent shear strength performance. Due to its composition of intertwined glass fibers, it possesses strong resistance to forces applied parallel to its surface. The interlocking fibers create a strong and rigid structure that allows it to withstand shear stresses and prevent deformation or failure. This makes fiberglass fabric highly suitable for applications where shear strength is important, such as in the construction of lightweight, high-strength composites, reinforcement of concrete, and the manufacturing of various industrial products. Additionally, fiberglass fabric's shear strength is not significantly affected by exposure to moisture, chemicals, or high temperatures, making it a durable and reliable material for a wide range of applications.

- Q: Can fiberglass fabric be used for making insulation boards?

- Yes, fiberglass fabric can be used for making insulation boards. It is a common material choice due to its excellent thermal insulation properties and fire resistance. The fabric is typically combined with other materials and processed into insulation boards to enhance their energy-saving capabilities and provide effective heat insulation.

- Q: How is fiberglass fabric used in the electrical industry?

- Fiberglass fabric is commonly used in the electrical industry as an insulation material for various electrical components. It is used to wrap and protect wires, cables, and other electrical devices to provide insulation and prevent electrical shocks. Additionally, fiberglass fabric is also used in the manufacturing of electrical panels and circuit boards to provide insulation and fire resistance.

- Q: Can fiberglass fabric be used for fire protection?

- Fiberglass fabric is indeed suitable for fire protection purposes. This material, being non-combustible, possesses exceptional fire-resistant properties. It boasts a high melting point and does not emit toxic fumes when exposed to flames. These qualities render fiberglass fabric an optimal choice for a myriad of fire protection applications. It finds common usage in fire curtains, fire blankets, and fire-resistant garments. The fabric's capacity to endure high temperatures and provide insulation against heat effectively establishes it as a formidable fire barrier. Moreover, fiberglass fabric is lightweight, flexible, and easily moldable into various shapes and sizes, thus offering versatility to cater to diverse fire protection requirements.

- Q: Can fiberglass fabric be used for reinforcement in marine applications?

- Yes, fiberglass fabric can be used for reinforcement in marine applications. Fiberglass fabric is a popular choice for reinforcing and strengthening various parts of boats and other marine structures. It is known for its high strength-to-weight ratio, making it an ideal material for improving the structural integrity of marine components. Fiberglass fabric is commonly used to reinforce hulls, decks, bulkheads, and other parts of boats. It is also used in the construction of sailboats, powerboats, yachts, and other watercraft. The fabric can be applied in multiple layers, providing additional strength and durability. One of the key advantages of fiberglass fabric in marine applications is its resistance to water and corrosion. It does not absorb water, making it highly suitable for marine environments where exposure to moisture, saltwater, and other harsh conditions is common. Fiberglass fabric is also resistant to UV radiation, which is crucial for maintaining the structural integrity and appearance of marine components. Furthermore, fiberglass fabric offers excellent dimensional stability, meaning it can retain its shape and strength over time. This is especially important in marine applications where boats and structures are subjected to constant movement, vibrations, and varying loads. In summary, fiberglass fabric is a versatile and reliable material for reinforcing marine applications. Its high strength-to-weight ratio, resistance to water and corrosion, and excellent dimensional stability make it a popular choice among boat builders and marine engineers.

- Q: How does fiberglass fabric perform in terms of dimensional stability?

- Fiberglass fabric offers excellent dimensional stability due to its inherent strength and rigidity. It is resistant to stretching, shrinking, and warping, making it an ideal choice for applications where maintaining shape and size is crucial.

- Q: Can fiberglass fabric be used for making shower curtains?

- Absolutely! When it comes to making shower curtains, fiberglass fabric is a stellar choice. Renowned for its durability, water resistance, and effortless upkeep, it's an ideal material. This fabric resists mildew and mold, which are frequent concerns in bathrooms, and can withstand the moisture and humidity found in shower areas. What's more, fiberglass fabric is a breeze to clean and doesn't absorb water, preventing saturation or unpleasant odors. All in all, opting for fiberglass fabric to create shower curtains ensures a lasting and hygienic solution for any bathroom.

- Q: Are there any environmental considerations associated with fiberglass fabrics?

- Yes, there are several environmental considerations associated with fiberglass fabrics. Firstly, the production of fiberglass fabrics involves the extraction of raw materials, such as silica sand and limestone, which can have negative impacts on the environment due to habitat destruction and landscape alteration. Additionally, the manufacturing process of fiberglass fabrics requires significant energy consumption, which contributes to greenhouse gas emissions and climate change. Furthermore, the use of fiberglass fabrics often involves the use of toxic chemicals, such as resins and adhesives, which can be harmful to both human health and the environment. These chemicals can potentially leach into soil and water sources, posing risks to ecosystems and biodiversity. Moreover, fiberglass fabrics are not biodegradable and can persist in the environment for a long time. If not properly managed at the end of their life cycle, they can contribute to waste accumulation in landfills or incineration, both of which have their own environmental impacts. However, it is important to note that fiberglass fabrics also have some positive environmental aspects. They are highly durable and have a long lifespan, which can reduce the need for frequent replacements, thus saving resources. Additionally, fiberglass fabrics can have energy-saving properties when used in insulation and construction materials, which can contribute to reducing energy consumption and greenhouse gas emissions in the long run. Overall, while there are environmental considerations associated with fiberglass fabrics, their impact can be mitigated through sustainable production practices, proper waste management, and consideration of alternative, more eco-friendly materials.

- Q: Is fiberglass fabric resistant to fire in public buildings?

- Yes, fiberglass fabric is indeed resistant to fire and is commonly used in public buildings for its fire-retardant properties. Fiberglass fabric is made from woven glass fibers that are highly heat resistant and do not easily catch fire. It has a high melting point, which means it will not ignite or support combustion easily. Moreover, fiberglass fabric is often treated with fire-resistant coatings or chemicals to further enhance its fire resistance. These properties make it an ideal material for use in public buildings, where safety and fire protection are of utmost importance.

Send your message to us

High Quality Fiberglass Fabrics - E Glass Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords