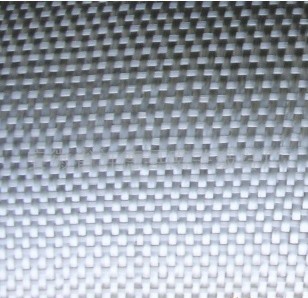

Fabric for Fiberglass - E-Glass Surfboards Fiberglass Fabric for Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabric is weaved of high quality C-glass fibers or E-glass fibers.

Fiberglass fabric is a good construction material with the following excellent properties

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

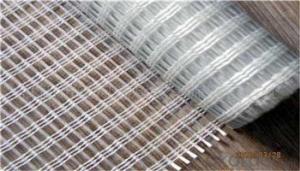

Packing of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabric is wound on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

Storage of E-glass Surfboards Fiberglass Fabric:

Store rolls in a cool, dry location

Protect rolls from weather and other damage.

- Q: How does fiberglass fabric perform in extreme temperatures in HVAC systems?

- HVAC systems are well aware of the exceptional performance of fiberglass fabric in extreme temperatures. This material is perfect for insulation because it can endure high temperatures without compromising its structural integrity or insulation properties. When it comes to hot environments, fiberglass fabric acts as a barrier, blocking the transfer of heat between different areas within the HVAC system. It effectively traps heat within the desired space, ensuring energy efficiency and minimizing heat loss. Similarly, in cold temperatures, fiberglass fabric functions as an insulator, preventing heat from escaping and maintaining a consistent temperature within the HVAC system. This reduces energy consumption and ensures optimal performance. Moreover, fiberglass fabric is fire-resistant and does not emit toxic gases when exposed to extreme temperatures. This makes it a safe option for HVAC systems, as it does not contribute to the spread of fires or pose health hazards in case of accidental overheating. Another advantage of fiberglass fabric in extreme temperatures is its durability and long lifespan. It remains intact and unimpaired when subjected to high or low temperatures, making it suitable for prolonged use in HVAC systems. It can withstand the thermal cycling that occurs within the system without compromising its insulation properties or structural integrity. In conclusion, fiberglass fabric is a reliable and efficient material for extreme temperatures in HVAC systems. It offers insulation, energy efficiency, safety, and durability, making it a popular choice for various HVAC applications.

- Q: Can fiberglass fabric be used for reinforcing concrete?

- Yes, fiberglass fabric can be used for reinforcing concrete. Fiberglass fabric is a lightweight and strong material made from fine glass fibers. It is commonly used as a reinforcement material in various industries, including construction. When used in concrete reinforcement, fiberglass fabric helps to improve the tensile strength and durability of the concrete structure. Fiberglass fabric is particularly beneficial in concrete reinforcement due to its high strength-to-weight ratio. It provides excellent resistance to corrosion, chemical attack, and weathering, making it suitable for both interior and exterior applications. Additionally, fiberglass fabric is non-magnetic and non-conductive, making it a preferred choice in areas where electromagnetic interference or conductivity is a concern. The process of using fiberglass fabric for reinforcing concrete involves laying the fabric in between the layers of wet concrete during the construction process. The fabric acts as a reinforcement, distributing the tensile stresses across the entire concrete structure, thus increasing its overall strength and preventing cracks or fractures. Furthermore, fiberglass fabric is relatively easy to handle and install. It can be cut into different shapes and sizes to fit specific reinforcement requirements. The fabric can also be easily molded or wrapped around complex shapes, allowing for versatile use in various concrete structures such as beams, columns, walls, and slabs. Overall, fiberglass fabric is a reliable and effective material for reinforcing concrete. It offers numerous advantages, including high strength, resistance to corrosion, and ease of installation. Its use in concrete reinforcement helps to enhance the structural integrity and longevity of the concrete, making it a popular choice in the construction industry.

- Q: What is the heat resistance of fiberglass fabric?

- Fiberglass fabric boasts a remarkable resistance to heat, enabling it to endure temperatures as high as 1000 degrees Fahrenheit (537 degrees Celsius) without experiencing notable harm or deterioration. This outstanding characteristic renders it an exceptional selection for various purposes that entail exposure to extreme heat, including welding blankets, insulation materials, and fire-resistant clothing. Moreover, fiberglass fabric exhibits a low thermal conductivity, signifying its limited ability to conduct heat effectively, thereby offering an extra shield of defense in environments with elevated temperatures.

- Q: Can fiberglass fabric be used for air ducts?

- Indeed, air ducts can make effective use of fiberglass fabric. Given its exceptional thermal and acoustic insulation attributes, fiberglass fabric has become a favored option for insulating air ducts. Its lightweight composition, flexibility, and resistance to fire, moisture, and mold growth make it an ideal material for incorporation into air duct systems. Moreover, the installation of fiberglass fabric is simple, and it aids in enhancing energy efficiency by minimizing heat loss or gain through the ductwork. Nevertheless, it is crucial to verify that the fiberglass fabric utilized in air ducts adheres to industry standards and regulations to guarantee optimal performance and safety.

- Q: How is fiberglass fabric used in the production of fire-resistant blankets?

- Fiberglass fabric is used in the production of fire-resistant blankets as it provides excellent thermal insulation properties and is highly resistant to heat and flames. The fabric is woven using fine glass fibers that create a strong and durable material capable of withstanding intense heat. When used in fire-resistant blankets, fiberglass fabric helps to create a protective barrier that can shield individuals or objects from the dangers of fire, providing a crucial layer of safety and protection.

- Q: How is fiberglass fabric used in the production of insulation sleeves?

- Fiberglass fabric is used in the production of insulation sleeves due to its excellent thermal properties and durability. Insulation sleeves are designed to provide thermal insulation and protection for various applications, such as industrial pipes, wires, and cables. When manufacturing insulation sleeves, fiberglass fabric is typically used as the outer layer due to its high resistance to heat and fire. The fabric acts as a barrier, preventing heat transfer and minimizing the risk of fire hazards. This is particularly important in industrial settings where high temperatures are present, as it helps to maintain a safe working environment. Additionally, fiberglass fabric is known for its insulation capabilities. It has a low thermal conductivity, meaning it is a poor conductor of heat. This property allows the fabric to effectively trap heat within the insulation sleeve, preventing energy loss and reducing the need for excessive heating or cooling. Furthermore, fiberglass fabric is highly durable and can withstand harsh environmental conditions, chemicals, and UV radiation. This makes it suitable for insulation sleeves that are exposed to outdoor elements or corrosive substances. The fabric also has good tensile strength, allowing it to withstand mechanical stress and maintain its shape over time. In summary, the use of fiberglass fabric in the production of insulation sleeves is essential for providing thermal insulation, fire protection, and durability. Its excellent thermal properties, resistance to heat and fire, and ability to withstand harsh conditions make it an ideal material for insulating various applications in industries such as construction, automotive, and manufacturing.

- Q: Is fiberglass fabric resistant to birds?

- No, fiberglass fabric is not inherently resistant to birds. Birds can easily peck and damage fiberglass fabric if they come into contact with it.

- Q: Is fiberglass fabric resistant to moisture in marine environments?

- Yes, fiberglass fabric is highly resistant to moisture in marine environments. It does not absorb water and maintains its structural integrity even when exposed to saltwater or high humidity. This makes it an excellent choice for various marine applications, such as boat hulls, decks, and other components that need to withstand constant exposure to moisture.

- Q: Can fiberglass fabrics be custom-designed or printed on?

- Fiberglass fabrics possess the capacity for customization and printing. Their versatility enables effortless adaptation to meet precise design demands. The printing procedure encompasses the application of diverse techniques, such as screen printing, digital printing, or transfer printing, to embed designs or patterns onto the fabric. This grants limitless opportunities for customization, encompassing the integration of logos, images, or distinctive designs. Custom-designed or printed fiberglass fabrics find extensive application in sectors like fashion, interior design, automotive, and aerospace, where aesthetic allure and branding hold significant significance.

- Q: What's the price of fiberglass fabric penetrant?

- The company has strong technical ability, can help customers solve various formulations problems.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fabric for Fiberglass - E-Glass Surfboards Fiberglass Fabric for Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords