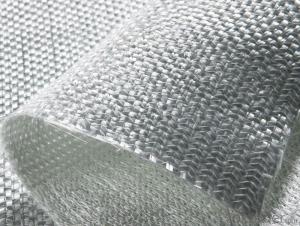

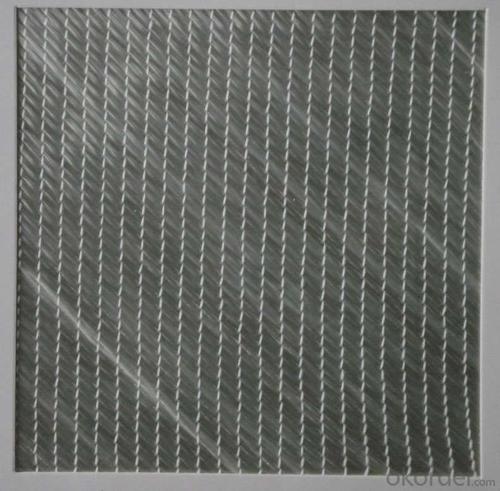

Fiberglass Mat Tissue E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

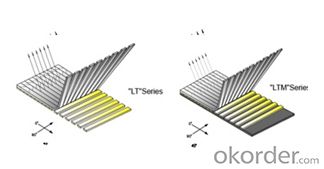

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for architectural facades?

- Indeed, architectural facades can make use of fiberglass mat tissue. This lightweight and flexible material finds wide application in diverse construction projects, including architectural facades. It boasts numerous benefits, ranging from its impressive strength and durability to its exceptional resistance against weather and fire. Moreover, fiberglass mat tissue lends itself easily to molding into various shapes and sizes, thus proving suitable for intricate and distinctive architectural designs. Its adaptability and visual allure render it a favored option among architects and designers when aiming to fashion visually pleasing and practical facades.

- Q: What are the different surface finishes available for fiberglass mat tissue?

- Some common surface finishes available for fiberglass mat tissue include smooth, textured, embossed, and matte finishes. These finishes can provide various aesthetic effects and enhance the performance of the fiberglass mat tissue in different applications.

- Q: What are the main applications of fiberglass mat tissue?

- The main applications of fiberglass mat tissue include reinforcement in the construction industry for roofing, walls, and flooring, as well as insulation in thermal and acoustic systems. It is also used in the manufacturing of automotive parts, boats, and pipes for their strength and durability. Additionally, it finds use in the production of printed circuit boards and as a filtration medium in air and liquid filtration systems.

- Q: Can fiberglass mat tissue be used for pipe wrapping?

- Yes, fiberglass mat tissue can be used for pipe wrapping. Fiberglass mat tissue is a lightweight and flexible material that is commonly used for reinforcing and protecting various structures, including pipes. It is designed to provide strength and durability to the pipes, making them more resistant to damage and corrosion. The fiberglass mat tissue can be easily wrapped around the pipe, creating a protective layer that helps to prevent leaks and extend the lifespan of the pipe. Additionally, fiberglass mat tissue is also known for its excellent insulation properties, which can help to maintain the temperature of the contents flowing through the pipe. Overall, fiberglass mat tissue is a suitable material for pipe wrapping and is commonly used in various industries for this purpose.

- Q: Does fiberglass mat tissue require any special precautions during handling?

- Special precautions are necessary when handling fiberglass mat tissue. This type of tissue comprises minuscule glass fibers that can cause irritation to the skin, eyes, and respiratory system if not handled properly. To reduce the risk of direct contact with the skin and eyes, it is imperative to wear protective clothing, including gloves, long sleeves, and goggles. Furthermore, working in a well-ventilated area or utilizing a respirator is highly recommended to prevent the inhalation of airborne fiberglass particles. To avoid the creation of additional airborne particles, it is advisable to handle the fiberglass mat tissue delicately. By implementing these precautions, the potential health risks associated with handling fiberglass mat tissue can be minimized.

- Q: Can fiberglass mat tissue be used for reinforcing wind turbine blades?

- Wind turbine blades can be reinforced using fiberglass mat tissue, a lightweight and flexible material composed of thin glass fibers bonded with resin. This material is frequently employed in various applications requiring strength and durability, including wind turbine blade construction. To efficiently harness wind power, turbine blades must possess strength while remaining lightweight. They face various forces, such as wind loads, vibrations, and extreme weather conditions. Fiberglass mat tissue is an ideal option for reinforcing these blades due to its exceptional mechanical properties. It offers high tensile strength and stiffness, enabling the blades to withstand the stress and strain they encounter during operation. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion and fatigue, which are crucial factors for ensuring the long-term performance of wind turbine blades. It also maintains good dimensional stability, preserving the shape and integrity of the blades over time. Moreover, fiberglass mat tissue can be easily shaped and molded, allowing for the creation of complex and aerodynamic blade designs. It can be layered and combined with other materials, such as epoxy resin, to form a composite structure that optimizes the strength and performance of wind turbine blades. In conclusion, fiberglass mat tissue is a widely used and suitable material for reinforcing wind turbine blades. Its lightweight nature, high strength, corrosion resistance, and moldability make it an excellent choice for maintaining the structural integrity and efficiency of wind turbines.

- Q: What is the expected lifespan of fiberglass mat tissue in outdoor applications?

- The durability of fiberglass mat tissue when used outdoors can be influenced by a variety of factors, including exposure to weather conditions, maintenance efforts, and material quality. On average, fiberglass mat tissue is designed to last approximately 20 to 30 years in outdoor applications. Fiberglass mat tissue finds widespread usage in outdoor industries such as roofing, construction, and automotive, where it provides reinforcement and strength to surfaces. Its notable characteristics include durability, moisture resistance, and the ability to withstand harsh weather conditions. To ensure an extended lifespan for fiberglass mat tissue in outdoor applications, proper maintenance and protection are vital. Regular inspections, cleaning, and timely repairs can help prevent potential damage and deterioration. Furthermore, the application of protective coatings or sealants can enhance its resistance to UV rays, moisture, and other environmental factors. It is worth mentioning that the lifespan of fiberglass mat tissue may differ based on the specific application and the quality of the material employed. Therefore, it is advisable to consult the manufacturer or an industry professional to determine the expected lifespan for a particular project or application.

- Q: Can fiberglass mat tissue be used for decorative applications?

- Yes, fiberglass mat tissue can be used for decorative applications. Its versatility and ability to be molded into various shapes make it suitable for creating decorative elements such as wall panels, sculptures, and other artistic installations. Additionally, its lightweight nature, durability, and resistance to corrosion make it an ideal choice for both indoor and outdoor decorative applications.

- Q: How does fiberglass mat tissue compare to spray foam insulation?

- Fiberglass mat tissue and spray foam insulation are two different types of insulation materials with their own unique characteristics and benefits. Fiberglass mat tissue is a type of insulation made from woven strands of fiberglass. It is typically used in applications where thermal insulation is required, such as in walls, roofs, and attics. Fiberglass mat tissue is known for its high resistance to heat transfer, making it an effective insulator. It is also fire-resistant, which adds an additional safety benefit. On the other hand, spray foam insulation is a type of insulation that is applied as a liquid and expands into a solid foam. It can fill in small cracks and gaps, creating an airtight seal, which makes it an excellent choice for preventing air leakage and reducing energy loss. Spray foam insulation is also known for its excellent soundproofing qualities. In terms of installation, fiberglass mat tissue usually comes in large rolls or batts that need to be cut and fitted into place. It requires careful handling to ensure proper installation and may require the use of protective equipment, such as gloves and masks, as the fibers can cause skin and respiratory irritation. Spray foam insulation, on the other hand, is applied using specialized equipment that sprays the liquid foam onto the desired surface. It expands quickly, filling in any gaps or voids, and hardens within a short period of time. This makes it a more convenient option for insulating hard-to-reach areas or irregularly shaped spaces. When comparing the two, fiberglass mat tissue is generally more cost-effective, as it is less expensive to purchase and install compared to spray foam insulation. However, spray foam insulation provides better air sealing and can offer higher energy savings in the long run. In summary, fiberglass mat tissue and spray foam insulation have their own advantages and are suited for different insulation needs. Fiberglass mat tissue is a good option for thermal insulation, while spray foam insulation excels in air sealing and soundproofing. The choice between the two ultimately depends on factors such as budget, desired insulation performance, and the specific requirements of the project.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Yes, fiberglass mat tissue can be used for making boat hulls. It is commonly used in boat manufacturing due to its strength, durability, and ability to provide structural reinforcement.

Send your message to us

Fiberglass Mat Tissue E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords