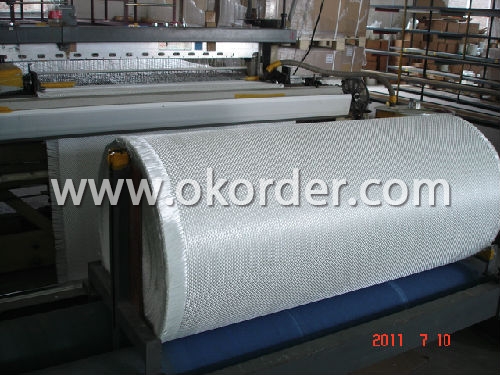

Ewr400 Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications OF EWR400

1. Low Fuzz,dirt,impurity and other stains.

2. Fast wet-out.

3. Even thickness

4.Good covering

5.Passed ISO9001,ISO14001

Characteristics of EWR400

Woven Roving is a high –performance reinforcement widely used in hand lay-up and machanical production

1) Good moldability & drapability

2) High strength

3) Excellent rollout characteristics

4) Fast wet -out

Application OF EWR400

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: Can fiberglass fabric be used for insulation in aerospace applications?

- Yes, fiberglass fabric can be used for insulation in aerospace applications. It is a common choice due to its excellent thermal resistance, lightweight nature, and resistance to high temperatures. Additionally, fiberglass fabric provides good sound insulation, making it suitable for aerospace environments.

- Q: How does fiberglass fabric compare to carbon fiber fabric?

- Fiberglass fabric and carbon fiber fabric are both popular materials used in various industries for their exceptional strength and durability. However, there are some key differences between these two fabrics that set them apart. One of the major differences is their composition. Fiberglass fabric is made from fine strands of glass that are woven together to form a fabric. On the other hand, carbon fiber fabric is composed of thin strands of carbon atoms that are tightly woven into a fabric. This fundamental difference in composition leads to variations in their mechanical properties and performance. In terms of strength, carbon fiber fabric has a higher tensile strength than fiberglass fabric. It is known for its exceptional stiffness and low weight, making it highly desirable for applications that require high strength-to-weight ratios. Carbon fiber is utilized in aerospace, automotive, and sports industries where lightweight and strong materials are crucial. Fiberglass fabric, on the other hand, offers good tensile strength but is generally less strong than carbon fiber. However, fiberglass fabric is known for its excellent impact resistance and can withstand high temperatures better than carbon fiber. This makes it suitable for applications where heat resistance and impact resistance are important, such as insulation, boat building, and electrical insulation. Another significant difference between these two fabrics is their cost. Carbon fiber fabric is considerably more expensive than fiberglass fabric due to the complexity and cost of the manufacturing process involved in producing carbon fiber. Fiberglass fabric, being more readily available and easier to produce, is comparatively more affordable. Additionally, carbon fiber fabric has a distinctive appearance with its black, glossy finish, while fiberglass fabric is typically white or off-white in color. This aesthetic difference can be a factor in certain applications where visual appeal is important. In summary, fiberglass fabric and carbon fiber fabric have their own unique properties and advantages. Carbon fiber fabric offers superior strength, stiffness, and lightweight characteristics, making it ideal for high-performance applications. Fiberglass fabric, on the other hand, excels in impact resistance and heat resistance, making it suitable for applications where these properties are crucial. Ultimately, the choice between these two fabrics depends on the specific requirements of the intended application, taking into consideration factors such as strength, weight, cost, and environmental conditions.

- Q: Can fiberglass fabric be laminated with other materials?

- Yes, fiberglass fabric can be laminated with other materials. Lamination involves bonding or layering different materials together, and fiberglass fabric is often used as a reinforcing layer in composite laminates. It can be combined with various materials such as resins, foams, or metals to enhance strength, durability, or other desired properties in the final product.

- Q: How does fiberglass fabric perform in terms of dimensional stability?

- Fiberglass fabric offers excellent dimensional stability due to its inherent strength and rigidity. It is resistant to stretching, shrinking, and warping, making it an ideal choice for applications where maintaining shape and size is crucial.

- Q: Can fiberglass fabrics be used for reinforcement in boats or yachts?

- Yes, fiberglass fabrics are commonly used for reinforcement in boats or yachts due to their high strength-to-weight ratio, excellent durability, and resistance to water and corrosion. Their flexibility and ability to conform to complex shapes make them ideal for reinforcing various parts of boats and yachts, such as hulls, decks, and bulkheads.

- Q: Is fiberglass fabric resistant to mold or mildew growth?

- Yes, fiberglass fabric is generally resistant to mold or mildew growth due to its non-porous nature and ability to repel moisture.

- Q: With what glue can stick glass steel cans?

- The modified epoxy adhesive can stick to the FRP tank;In addition to the epoxy resin and other non-polar polyolefin plastic adhesive is not good, for all kinds of metal materials such as aluminum, steel, iron, copper; non metallic materials such as glass, wood and concrete; and thermosetting plastics such as phenolic, amino, unsaturated polyester has excellent adhesive properties, so it is called monengjiao. Epoxy adhesive is an important kind of structural adhesive.

- Q: How to deal with cracks in floor construction joints?

- The cracks that do not affect the safety of the structure shall be used in combination with the following methods:Chemical grouting: suitable for through cracks, the use of special pressure equipment, the chemical pulp into the hydraulic pressure, the general chemical grout for epoxy resin, polyurethane and so on.In the original position of the crack sealing slot slot, groove clean, sealing material for fill block, sealing material with epoxy grout, sealing compound, polymer mortar etc..

- Q: What are the different weaving patterns available for fiberglass fabric?

- There are several different weaving patterns available for fiberglass fabric, each with its own unique characteristics and applications. 1. Plain Weave: This is the most basic and commonly used weaving pattern for fiberglass fabric. It consists of a simple over-and-under interlacing of warp and weft yarns, creating a balanced and uniform fabric structure. Plain weave fiberglass fabric offers good strength, dimensional stability, and is suitable for a wide range of applications. 2. Twill Weave: Twill weave creates a diagonal pattern on the fabric surface, achieved by passing the weft yarn over multiple warp yarns before going under. This weaving pattern enhances the fabric's drapability, flexibility, and allows for better conformability to complex shapes. Twill weave fiberglass fabric is often used in applications where flexibility and durability are required, such as in the aerospace and automotive industries. 3. Satin Weave: Satin weave is characterized by long floats, where the weft yarn passes over multiple warp yarns before going under. This creates a smooth and lustrous surface with less crimp and higher yarn density. Satin weave fiberglass fabric offers excellent drapeability, high strength-to-weight ratio, and is commonly used in applications that require a high-quality surface finish, such as marine and sporting goods industries. 4. Leno Weave: Leno weave is a unique pattern where the warp yarns are twisted around each other, creating an open and flexible structure. This weaving pattern enhances the fabric's breathability and allows for better resin impregnation during composite fabrication. Leno weave fiberglass fabric is often used in applications such as filtration, reinforcement in composites, and as a base fabric for laminates. 5. Jacquard Weave: Jacquard weave is a complex pattern created by individually controlling each warp yarn. This weaving technique allows for intricate designs, patterns, and textures to be woven into the fabric. Although less common in fiberglass fabric, jacquard weave can be used to create custom designs or specific functional features in specialized applications. Overall, the choice of weaving pattern for fiberglass fabric depends on the desired properties, performance requirements, and intended applications. Each weaving pattern offers unique characteristics and advantages, allowing for a wide range of possibilities in utilizing fiberglass fabric across various industries.

- Q: Can fiberglass fabric be used for heat-resistant blankets?

- Indeed, heat-resistant blankets can be made using fiberglass fabric. Fiberglass, a remarkably heat-resistant substance, has the ability to endure high temperatures without any signs of melting or deterioration. Its exceptional thermal insulation qualities make it an optimal selection for heat-resistant blankets. Fiberglass fabric blankets have diverse applications, including welding, foundries, fire protection, and heat shielding. These blankets deliver dependable defense against heat, flames, and sparks, making them a trustworthy option for environments where heat resistance is of utmost importance.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Above US$20 Million |

| Main Markets | Mid East;Western Europe;North America:South American |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 400,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | Average |

| Product Price Range | OEM Service Offered;Design Service Offered |

Send your message to us

Ewr400 Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords