Fiberglass Fabric Lowes Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

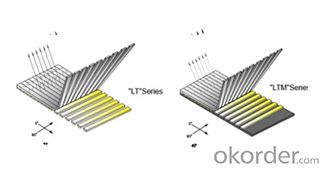

(0°/90°) series mat:

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡)。The product has a maximum width of 100 inches.This product can be used for manufacturing boats,cases and shell of car.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-LTMC3205 | 1272.69 | 607.6 | 491.86 | 152.58 | 20.65 |

E-LTMC3205-HS | 1388.43 | 607.6 | 607.6 | 152.58 | 20.65 |

E-LTMC3208 | 1394.75 | 607.6 | 491.86 | 274.64 | 20.65 |

E-LTMC3610 | 1541 | 607.6 | 607.6 | 305.15 | 20.65 |

E-LTMC3615 | 1693.58 | 607.6 | 607.6 | 457.73 | 20.65 |

E-LTC1800 | 629.16 | 303.8 | 307 | - | 18.36 |

E-LTC2400 | 826.4 | 405.66 | 401.46 | - | 19.28 |

E-LTC3600 | 1235.85 | 607.6 | 607.6 | - | 20.65 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

E-UDLM1250 | 1258.98 | 1133.86 | 55.12 | 50.00 | 20 |

E-UDLM1300 | 1338.68 | 1215.2 | 55.12 | 50.00 | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- Diluent can also be added as a diluent substance is hydrocarbons, and their boiling point should be 100~200 degrees. But in any case, the boiling point of the diluent used should be lower than the dispersant. Some swelling effect of aromatics is on PVC resin, almost no Naphthalene Hydrocarbons, aliphatic hydrocarbon is not completely.

- Q: How is fiberglass fabric used in the filtration industry?

- Fiberglass fabric is widely used in the filtration industry due to its excellent properties and versatility. It is commonly employed in various filtration applications such as air filters, liquid filters, dust collectors, and industrial filtration systems. One of the key advantages of fiberglass fabric in filtration is its high strength and durability. The fabric is made by weaving fine strands of glass fibers together, creating a strong and resilient material that can withstand harsh filtration conditions. This makes it suitable for both high-pressure and high-temperature filtration processes. Furthermore, fiberglass fabric has excellent chemical resistance, making it ideal for filtering corrosive substances or liquids. It is resistant to a wide range of chemicals, solvents, and acids, ensuring that the filtration material does not degrade or react with the filtrate. Another crucial attribute of fiberglass fabric is its high porosity and filtration efficiency. The fabric can be engineered to have specific pore sizes, allowing for the effective removal of different particle sizes and contaminants. It provides a reliable barrier, preventing the passage of undesired particles while allowing the desired filtrate to pass through. Additionally, fiberglass fabric is known for its low resistance to airflow, making it an excellent choice for air filtration applications. It enables efficient air circulation by allowing the passage of clean air while capturing and retaining airborne particles such as dust, pollen, and allergens. Moreover, fiberglass fabric is easy to maintain and clean, increasing its lifespan and efficiency. It can be easily cleaned through various methods such as backwashing, reverse air cleaning, or chemical cleaning, ensuring that it remains effective over time. In summary, fiberglass fabric is a valuable component in the filtration industry due to its strength, durability, chemical resistance, porosity, and filtration efficiency. Its use in air filters, liquid filters, dust collectors, and industrial filtration systems helps to maintain clean and pure environments by effectively removing particles and contaminants.

- Q: The thickness of the stone concrete protection layer on the waterproof layer shall not be less than mm.

- Basement roof: non load protection layer generally use C20 fine stone concrete or reinforced concrete, thickness 50~80mm. The road and driving protective layer is determined by design.No roof: General waterproof layer, the above can be 15~25mm cement mortar protection.Upper roof: generally use 40 thick C20 reinforced concrete protection.The purpose of protection, one is to avoid man-made mechanical damage; the two is to prevent climate and UV aging, to prolong the service life; three in the planting roof protective layer to prevent plant roots in different functions using the method of thrust, different protection.

- Q: Can fiberglass fabric be used for making bookbinding material?

- Yes, fiberglass fabric can be used for making bookbinding material. Fiberglass fabric is a versatile material that is known for its strength, durability, and resistance to wear and tear. It can be used as a reinforcement material in bookbinding to provide added strength and stability to the covers and spines of books. It can also be used as a protective layer to prevent damage to the pages and bindings of books. However, it is important to note that fiberglass fabric can be quite rigid and may not be suitable for certain types of bookbinding projects that require flexibility or a softer touch. Therefore, it is recommended to assess the specific requirements of the bookbinding project before deciding to use fiberglass fabric.

- Q: How does fiberglass fabric perform in terms of dimensional stability?

- Fiberglass fabric exhibits excellent dimensional stability, making it highly reliable and suitable for a wide range of applications. Thanks to its unique composition of woven glass fibers, it possesses remarkable resistance to changes in shape or size, even under extreme temperature fluctuations or mechanical stress. This stability ensures that fiberglass fabric maintains its original dimensions and shape over time, allowing it to consistently meet the required specifications and performance criteria. Additionally, its dimensional stability makes fiberglass fabric ideal for applications where precise measurements and accuracy are necessary, such as in aerospace, automotive, and construction industries. Overall, fiberglass fabric's exceptional dimensional stability is one of its key attributes, contributing to its widespread use and popularity across various sectors.

- Q: How to identify the warp and weft direction of glass fiber cloth?

- If there is a side, the yarn parallel to the side is warp

- Q: Can fiberglass fabric be used for reinforcement in septic tanks?

- Yes, fiberglass fabric can be used for reinforcement in septic tanks. Fiberglass fabric is known for its strength and durability, making it an excellent choice for reinforcing structures, including septic tanks. The fabric can be used to reinforce the walls and base of the tank, providing additional strength and preventing cracks or leaks. Additionally, fiberglass fabric is resistant to corrosion, which is important in a septic tank environment where there can be high levels of sewage and chemicals. Overall, using fiberglass fabric for reinforcement in septic tanks can enhance their longevity and structural integrity.

- Q: Can fiberglass fabric be used for insulation in cryogenic systems?

- Yes, fiberglass fabric can be used for insulation in cryogenic systems.

- Q: How does fiberglass fabric handle humidity?

- Fiberglass fabric is known for its excellent resistance to humidity. Unlike many other materials, fiberglass fabric does not absorb moisture, making it highly resistant to mold and mildew growth. This characteristic makes fiberglass fabric a great choice for applications in high humidity environments, as it will not degrade or lose its structural integrity when exposed to moisture. Additionally, fiberglass fabric's resistance to humidity also makes it suitable for outdoor use, as it can withstand rain, fog, and other wet conditions without deteriorating. Overall, fiberglass fabric's ability to handle humidity makes it a durable and reliable material for a wide range of applications.

- Q: How to deal with thermal cracking of exterior wall?

- Find cause of cracking. It is possible that cracking is not caused by heat preservation itself, such as uneven settlement. At this time, don't mend the cracks first, then mend them again.

Send your message to us

Fiberglass Fabric Lowes Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords