Teflon Fiberglass Fabric Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

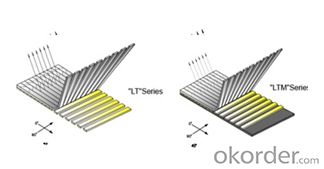

(0°/90°) series mat:

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡)。The product has a maximum width of 100 inches.This product can be used for manufacturing boats,cases and shell of car.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-LTMC3205 | 1272.69 | 607.6 | 491.86 | 152.58 | 20.65 |

E-LTMC3205-HS | 1388.43 | 607.6 | 607.6 | 152.58 | 20.65 |

E-LTMC3208 | 1394.75 | 607.6 | 491.86 | 274.64 | 20.65 |

E-LTMC3610 | 1541 | 607.6 | 607.6 | 305.15 | 20.65 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: How to do anti-corrosion of buried metal water supply pipeline?

- When the flow of a fluid is known, the size of the pipe depends on the allowed velocity or allowable frictional resistance (pressure drop). When the flow rate is large, the pipe diameter is small, but the pressure drop increases. Therefore, when the flow rate is large, the infrastructure investment of the pipeline can be saved, but the energy consumption of the power equipment such as pumps and compressors is increased. In addition, if the flow rate is too large, there may be other adverse factors. Therefore, the diameter should be determined according to the construction investment, operating costs and other technical factors.

- Q: How does fiberglass fabric perform in terms of mold and mildew resistance?

- Fiberglass fabric generally performs well in terms of mold and mildew resistance. This is mainly due to the non-porous nature of the material, which prevents moisture from being absorbed. Mold and mildew require a damp environment to grow and thrive, so the moisture resistance of fiberglass fabric helps to inhibit their growth. Additionally, fiberglass fabric is often treated with special coatings or finishes that enhance its resistance to mold and mildew. These treatments create a barrier on the fabric's surface, making it more difficult for mold and mildew spores to attach and grow. However, it is important to note that while fiberglass fabric has good resistance, it is not completely immune to mold and mildew. If the fabric is exposed to excessive moisture or if it is not properly cleaned and maintained, mold and mildew can still develop. Therefore, regular cleaning and proper care are essential to maintain the mold and mildew resistance of fiberglass fabric.

- Q: Are fiberglass fabrics easy to sew or work with?

- Sewing or working with fiberglass fabrics is typically not an easy task due to their unique properties and characteristics. Unlike other textiles, fiberglass fabrics are incredibly durable and resistant to heat, fire, chemicals, and most environmental factors. These qualities make them perfect for insulation, protective clothing, and adding strength to composites. However, these same properties also make them challenging to sew or work with. The primary difficulty in sewing fiberglass fabrics lies in their stiffness and rigidity. Unlike conventional fabrics, fiberglass fabrics lack flexibility, which makes them challenging to handle and manipulate. Their inability to stretch also makes it difficult to shape or contour them to fit certain designs. This can create complications when attempting to sew complex or intricate patterns using fiberglass fabrics. Furthermore, the sharp and abrasive nature of fiberglass fibers can cause damage to traditional sewing machines, needles, and threads. The sharp edges of the fibers can quickly wear down needles and lead to thread breakage or fraying. This can result in frustration and inefficiency when working with fiberglass fabrics. To overcome these challenges, specialized techniques and equipment are often necessary when sewing or working with fiberglass fabrics. This may involve the use of heavy-duty sewing machines, specialized needles and threads, and taking precautions to protect oneself from potential health hazards associated with fiberglass fibers. In conclusion, although fiberglass fabrics offer excellent performance and durability in various applications, they are not as easy to sew or work with compared to traditional textiles. The stiffness, lack of flexibility, and abrasive nature of the fibers require the use of specialized techniques and equipment to successfully work with these fabrics.

- Q: How does fiberglass fabric perform in high-humidity environments?

- Fiberglass fabric performs exceptionally well in high-humidity environments. Due to its non-absorbent nature, it does not retain moisture and remains unaffected by the presence of water vapor in the air. This means that even in high-humidity conditions, fiberglass fabric maintains its structural integrity, strength, and dimensional stability. It does not warp, shrink, or become brittle like some other materials in humid conditions. Additionally, the non-porous nature of fiberglass fabric prevents the growth of mold, mildew, and other fungi that thrive in moist environments. This makes fiberglass fabric an excellent choice for applications such as boat building, outdoor furniture, and construction projects in high-humidity areas. Overall, fiberglass fabric's resistance to moisture and its ability to withstand high-humidity environments make it a reliable and durable material in such conditions.

- Q: Can fiberglass fabrics be used for insulation in pipelines?

- Yes, fiberglass fabrics can be used for insulation in pipelines. They are commonly used due to their excellent thermal insulation properties, high temperature resistance, and durability.

- Q: Roof with a single group of waterproof coating and glass fiber cloth done, but the past is still in the seam water seepage, how should remediation?

- The 911 one component waterborne polyurethane waterproof coating, construction, processing the original leak, clean it up, the best to the original paint and glass fiber cloth clean, with 911 of one component waterborne polyurethane waterproof coating in the crevice of a brush, brush the width of the slot width is 200MM. Brush two more than the first width, the thickness of long to 1MM, third brush width of two width, thickness of 0.2MM can be.

- Q: How is fiberglass fabric sewn?

- Fiberglass fabric is typically sewn using a heavy-duty sewing machine equipped with a strong needle and thread. The process involves aligning the edges of the fabric panels and feeding them through the machine, allowing the needle to pierce through the fabric layers and create stitches. It is important to use a sharp needle specifically designed for sewing fiberglass fabric, as this material can be tough and abrasive, potentially causing regular needles to break or become dull quickly. Additionally, using a sturdy thread, such as a polyester or nylon thread, is crucial to ensure the durability and longevity of the seams. Sewing fiberglass fabric requires skill and precision, as the material can be slippery and difficult to handle. It is recommended to practice on scrap pieces before attempting to sew large or complex projects.

- Q: How is fiberglass fabric used in the production of insulation sheets?

- Fiberglass fabric is commonly used in the production of insulation sheets due to its excellent thermal insulation properties. The fabric is made by weaving fine strands of fiberglass together, creating a strong and durable material. In the production process of insulation sheets, fiberglass fabric is typically used as a reinforcement layer. First, a layer of fiberglass fabric is placed on top of the insulation material, which is usually made of foam or mineral wool. This fabric helps to enhance the strength of the insulation sheet and prevent tearing or damage during installation or use. Additionally, fiberglass fabric acts as a barrier, preventing the insulation material from shifting or settling over time. This helps to maintain the effectiveness and efficiency of the insulation by ensuring that it remains in place and does not create gaps or voids. Moreover, fiberglass fabric provides additional fire resistance to the insulation sheets. It has inherent fire-resistant properties, which can help to prevent the spread of flames and minimize the risk of fire hazards. This is particularly important in applications where insulation sheets are used in buildings or structures where fire safety is a concern. Furthermore, fiberglass fabric is also beneficial in terms of moisture resistance. It helps to create a moisture barrier, preventing water or moisture from penetrating the insulation material. This is crucial in maintaining the insulation's thermal performance, as moisture can significantly reduce its effectiveness. Overall, fiberglass fabric is an essential component in the production of insulation sheets, as it enhances strength, provides fire resistance, improves moisture resistance, and ensures long-lasting thermal insulation. Its versatile properties make it a reliable and widely used material in the insulation industry.

- Q: Can fiberglass fabric be used for making curtains or blinds?

- Yes, fiberglass fabric can be used for making curtains or blinds. It is a durable and versatile material that offers excellent light filtering and insulation properties, making it suitable for use in window coverings. Additionally, fiberglass fabric is resistant to fire, moisture, and fading, making it a practical choice for curtains or blinds in various settings.

- Q: How about the difference between glass fiber cloth and ordinary chemical fiber cloth?

- My major is chemical fiber. It's easy to tell apart! You can burn it with a fire. It can melt and drop like a candle. (careful not to stick to your body and burn it!) It's a synthetic fabric, not a fiberglass fabric.

Send your message to us

Teflon Fiberglass Fabric Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords