Ewr Silica Fiberglass Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER TON kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

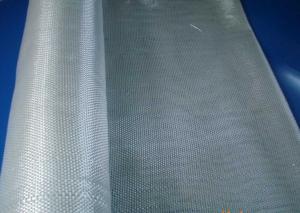

Specifications of EWR

1) Density (ends/cm): 3 x 3

2) Breaking strength (N): 2700 x 2500

3) Good quality

4) White color

5)plain weave

Applification of EWR

1) Width: 1000mm

2) Weight: 600±60g/m2

Packaging & Delivery of EWR

Packaging Detail: fiberglass fabric:plastic woven bag or carton,according custormers' demand

Delivery Detail: (15-20)days after received the deposit

- Q: Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- The auxiliary plasticizer can be added, and the dissolving capacity of the auxiliary plasticizer is relatively small, and when used, the viscosity is reduced and the storage is favorable.

- Q: Can fiberglass fabric be used for making tarpaulins?

- Tarpaulins can indeed be made using fiberglass fabric, which is renowned for its durability, strength, and ability to withstand harsh weather conditions. This versatile material finds widespread use in several applications, including tarpaulin production. Despite its lightweight nature, fiberglass fabric boasts exceptional tear resistance and can endure high temperatures. Moreover, its waterproof properties make it a perfect choice for safeguarding goods and equipment from rain, snow, and other environmental elements. In addition, fiberglass fabric's resistance to chemicals, UV rays, and mildew contributes to its longevity and enhances its performance as an ideal tarpaulin material.

- Q: Can fiberglass fabrics be used for insulation in cryogenic applications?

- Yes, fiberglass fabrics can be used for insulation in cryogenic applications. Fiberglass has excellent thermal properties and can effectively insulate against low temperatures typically found in cryogenic environments. It provides a high level of thermal resistance, preventing heat transfer and maintaining the desired temperature. Additionally, fiberglass fabrics are lightweight, durable, and resistant to moisture and chemicals, making them suitable for cryogenic insulation.

- Q: Are fiberglass fabrics resistant to UV degradation?

- Yes, fiberglass fabrics are generally resistant to UV degradation. Fiberglass is made from fine strands of glass woven together to create a strong and durable fabric. These glass fibers have inherent resistance to the harmful effects of UV radiation. This means that fiberglass fabrics can withstand prolonged exposure to sunlight without significant degradation. However, it is important to note that while fiberglass itself may be UV resistant, the coatings or finishes applied to the fabric may not be. Therefore, it is advisable to check the specific product specifications or consult with the manufacturer to ensure the level of UV resistance of a particular fiberglass fabric.

- Q: Is fiberglass fabric resistant to chemicals used in wastewater treatment?

- Yes, fiberglass fabric is highly resistant to chemicals used in wastewater treatment. Fiberglass is known for its exceptional chemical resistance, making it an ideal material for applications where exposure to various chemicals is likely. It can withstand a wide range of corrosive substances, including acids, alkalis, and solvents, commonly found in wastewater treatment processes. The non-reactive nature of fiberglass fabric ensures that it does not degrade or deteriorate when exposed to these chemicals, making it a reliable choice for use in wastewater treatment facilities. Additionally, fiberglass fabric is also resistant to UV radiation, moisture, and temperature fluctuations, further enhancing its durability and suitability for such environments.

- Q: How does fiberglass fabric perform in terms of dimensional stability?

- Fiberglass fabric exhibits excellent dimensional stability, making it highly reliable and suitable for a wide range of applications. Thanks to its unique composition of woven glass fibers, it possesses remarkable resistance to changes in shape or size, even under extreme temperature fluctuations or mechanical stress. This stability ensures that fiberglass fabric maintains its original dimensions and shape over time, allowing it to consistently meet the required specifications and performance criteria. Additionally, its dimensional stability makes fiberglass fabric ideal for applications where precise measurements and accuracy are necessary, such as in aerospace, automotive, and construction industries. Overall, fiberglass fabric's exceptional dimensional stability is one of its key attributes, contributing to its widespread use and popularity across various sectors.

- Q: Can fiberglass fabrics be used for waterproofing?

- Yes, fiberglass fabrics can be used for waterproofing. Fiberglass is a versatile material that is commonly used in various industries, including construction and marine applications, due to its excellent water-resistant properties. When used as a fabric, fiberglass can be coated with waterproof materials such as silicone or polyurethane to enhance its waterproofing abilities. These coatings create a barrier that prevents water from penetrating the fabric, making it an effective choice for waterproofing purposes. Additionally, fiberglass fabrics are also resistant to mildew and rot, which further enhances their suitability for waterproofing applications.

- Q: How do fiberglass fabrics perform in terms of chemical resistance?

- Fiberglass fabrics generally exhibit excellent chemical resistance. The inherent properties of fiberglass, including its non-reactivity and stability, make it highly resistant to a wide range of chemicals. Fiberglass fabrics can withstand exposure to various corrosive substances, including acids, bases, solvents, and even some strong oxidizing agents. The chemical resistance of fiberglass fabrics can be attributed to the composition of the material, as they are typically made of glass fibers woven together. Glass fibers are non-absorbent and do not react with most chemicals, making them highly resistant to degradation or damage. However, it is important to note that the chemical resistance of fiberglass fabrics can vary depending on the specific type of resin used to bind the fibers together. Different resins may have different levels of resistance to certain chemicals. Therefore, it is crucial to consider the specific application and the intended chemical exposure when selecting a fiberglass fabric. In summary, fiberglass fabrics are generally known for their excellent chemical resistance. They can withstand exposure to a wide range of chemicals without experiencing significant degradation or damage. However, it is always advisable to consult the manufacturer's specifications and recommendations to ensure the chosen fiberglass fabric is suitable for the intended chemical environment.

- Q: How is fiberglass fabric used in the medical industry?

- Fiberglass fabric is widely used in the medical industry for various purposes due to its unique properties and characteristics. One of the primary applications of fiberglass fabric in the medical industry is for the manufacturing of cast and splint materials. When a patient suffers from a fracture or a broken bone, fiberglass fabric is used in combination with a resin material to create a cast or splint that provides support and immobilization to the affected area. The fabric is soaked in a resin solution and then applied to the patient's limb, where it hardens and forms a rigid structure. The lightweight and durable nature of fiberglass fabric make it an ideal choice for these applications, as it provides the necessary rigidity and support while still allowing for mobility and comfort. Additionally, fiberglass fabric is also used in the manufacturing of prosthetics and orthotics. Prosthetics are artificial limbs or body parts that are used to replace missing or non-functional body parts, while orthotics are devices used to support, align, and improve the function of various body parts. Fiberglass fabric is often used as a reinforcement material in the construction of these devices, as it offers high strength and stability. The fabric is layered and bonded with other materials to create a strong and lightweight structure that can withstand the daily wear and tear. Furthermore, fiberglass fabric is utilized in the production of medical equipment such as surgical drapes and gowns. These fabrics are designed to provide a barrier against fluids and microorganisms to prevent contamination during surgical procedures. The non-porous nature of fiberglass fabric makes it an effective choice for these applications, as it prevents the penetration of fluids and maintains a sterile environment. Overall, fiberglass fabric plays a vital role in the medical industry by providing support, strength, and protection in various applications. Its versatility, durability, and ability to conform to different shapes and sizes make it an invaluable material for medical professionals in their efforts to provide optimal care and treatment to patients.

- Q: What are the differences in the quality and performance of domestic glass fiber cloth and imported fiberglass fabric?

- Domestic glass fiber: it is made up of two layers of non-woven fabric and three layers of glass fiber. The layer is not clear and the filter layer is thick. It is not easy to break the water in the oil. The precision is generally 1 - 100 microns

Company respected "steadfast, perseverance, responsibility" spirit of enterprise, and with integrity, win-win and create a business philosophy, to create a good environment of enterprise, with new management mode, perfect technology, and thoughtful service, excellent quality for survival, we always adhere to customer first service to customers, insist on their service to impress customers.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Above US$20 Million |

| Main Markets | Mid East;Western Europe;North America:South American |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 400,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | Average |

| Product Price Range | OEM Service Offered;Design Service Offered |

Send your message to us

Ewr Silica Fiberglass Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER TON kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords