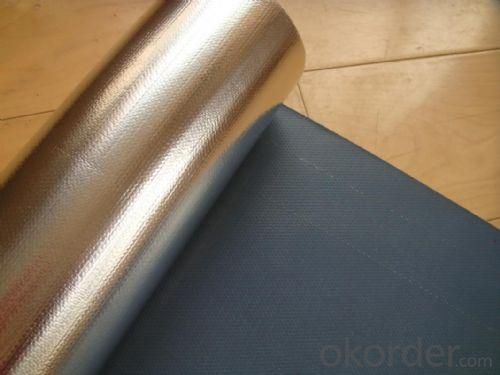

Fiberglass Fabrics Reinforced with High Quality Aluminium Foil

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of High Quality Fiberglass Fabrics Aluminium Foil:

The High Quality Fiberglass Fabrics Aluminium Foil is an engineering material weaved with glass fiber, which has the excellent merit such as anti-burns, anti-corrosion, stable-size, heat isolation, minimum elongated shrinkage, high intensity.It is widely used to make PVC fabric, water-proof material, free-proofing canvas and heat preservation materials.

Technical Data Sheet of High Quality Fiberglass Fabrics Aluminium Foil:

Fabric Count Warp×Fill(Per cm) | Yarn(SI)

| Thickness(mm) (Rreference Only) | Nominal Weight(g/m2) | Weight Tolerance(g/m2) |

23.6×18.5 | 5 11 1×0 5 11 1×0 | 0.053 | 46.8 | 45.1-48.5 |

23.6×23.6 | 5 11 1×0 5 11 1×0 | 0.056 | 52.9 | 51.5-54.2 |

19.3×16.5 | 7 45* 1×0 7 45* 1×0 | 0.149 | 164.1 | 157.7-170.5 |

18.1×17.7 | 7 45* 1×0 7 45* 1×0 | 0.140 | 1654.0 | 158.0-171.0 |

23.6×19.7 | 6 33 1×0 6 33 1×0 | 0.125 | 148.0 | 142.8-153.2 |

20.0×10.8 | 9 331×0 9 74 1×0 | 0.135 | 146.2 | 142.1-150.3 |

20.5×20.5 | 9 34* 1×0 9 34* 1×0 | 0.114 | 138.3 | 133.6-143. |

23.6×22.0 | 7 22 1×0 5 11 1×0 | 0.079 | 78.0 | 75.6-80.4 |

22.0×18.9 | 7 22 1×0 7 22 1×0 | 0.084 | 90.9 | 88.5-93.2 |

23.6×22.8 | 7 22 1×0 7 22 1×0 | 0.094 | 103.8 | 100.7-106.8 |

26.0×21.7 | 7 22 1×0 7 22 1×0 | 0.095 | 108 | 104.8-111.2 |

17.3×12.2 | 9 681×0 9 68 1×0 | 0.173 | 203.4 | 198.0-208.9 |

17.9×13.4 | 9 68 1×0 9 68 1×0 | 0.18 | 210.0 | 204.5-215.3 |

17.3×11.4 | 9 68 1×0 9 102* 1×0 | 0.201 | 232.3 | 226.5-238.0 |

17.5×7.9 | 9 68 1×0 9 136* 1×0 | 0.254 | 227.8 | 221.1-234.7 |

17.4×10 | 9 68 1×0 9 136* 1×0 | 0.250 | 260.0 | 255.2-265.3 |

- Q: Can fiberglass fabric be used for insulation in industrial ovens?

- Indeed, insulation in industrial ovens can be achieved through the utilization of fiberglass fabric. Possessing exceptional thermal insulation properties, fiberglass fabric proves to be an ideal selection due to its capacity to endure high temperatures. By effectively capturing and confining heat within the oven, it enhances energy efficiency. Furthermore, the durability, resistance to chemical and moisture exposure, as well as low thermal conductivity of fiberglass fabric contribute to its reliability and longevity as a superior insulating option for industrial ovens.

- Q: Can fiberglass fabric be used for making flags and banners?

- Yes, fiberglass fabric can be used for making flags and banners. Fiberglass fabric is known for its durability, strength, and resistance to weather conditions, making it an ideal material for outdoor applications such as flags and banners. It is lightweight and flexible, allowing for easy handling and installation. Additionally, fiberglass fabric can be printed on using various techniques, ensuring vibrant and long-lasting colors on the flags and banners. Overall, fiberglass fabric is a reliable choice for creating flags and banners that are both visually appealing and durable.

- Q: What are the different fiberglass fabric coatings for chemical resistance?

- The market offers various fiberglass fabric coatings, each with excellent chemical resistance. Some commonly utilized coatings include: 1. PVC Coating: PVC coating exhibits favorable chemical resistance to acids, alkalis, and solvents. It finds widespread use in applications necessitating protection against corrosive chemicals. 2. PU Coating: PU coating boasts exceptional resistance to abrasion, chemicals, and oils. It is frequently employed in applications where the fabric must endure harsh chemical environments. 3. Fluoropolymer Coating: Fluoropolymer coatings, like PTFE and FEP, provide outstanding chemical resistance to corrosive chemicals, acids, and solvents. These coatings find extensive usage in industries such as chemical processing, pharmaceuticals, and food processing. 4. Silicone Coating: Silicone coating offers commendable resistance to chemicals, oils, and extreme temperatures. It is commonly utilized in applications requiring both chemical resistance and high-temperature resistance. 5. Neoprene Coating: Neoprene coating delivers excellent resistance to a wide array of chemicals, oils, and solvents. It is frequently employed in applications where the fabric must withstand exposure to aggressive chemicals. It is crucial to consider the specific chemical environment and the desired level of resistance when selecting a coating. Consulting a technical expert or coating manufacturer is recommended to identify the most suitable fiberglass fabric coating for a particular chemical resistance application.

- Q: Are fiberglass fabrics suitable for use in the energy sector?

- Fiberglass fabrics prove to be apt for utilization in the energy sector. These fabrics consist of woven glass fibers and are renowned for their robustness, longevity, and ability to endure heat, chemicals, and corrosion. These exceptional characteristics render them suitable for a diverse range of applications within the energy sector. Thermal insulation stands as one key application of fiberglass fabrics in the energy sector. They find common use in insulating pipes, tanks, and equipment in power plants, oil refineries, and other energy facilities. The remarkable thermal resistance of fiberglass effectively diminishes heat loss, amplifies energy efficiency, and ensures the maintenance of desired temperature levels within these applications. Additionally, fiberglass fabrics are instrumental in the construction of wind turbine blades. The combination of high strength and lightweight properties makes fiberglass an ideal material for manufacturing wind turbine blades. These blades necessitate the capability to withstand strong winds while efficiently generating electricity. Fiberglass fabrics offer the essential structural integrity and aerodynamic properties vital for wind turbines. Moreover, fiberglass fabrics play a significant role in the production of fuel cells and solar panels. The chemical and corrosion resistance of fiberglass renders it a suitable material for constructing the casings and components of these energy systems. The durability of fiberglass further guarantees the long-term performance and reliability of these energy technologies. In summary, fiberglass fabrics provide numerous advantages and are perfectly suited for utilization in the energy sector. Their exceptional strength, durability, resistance to heat and chemicals, and lightweight nature make them the preferred choice for various applications, including thermal insulation, wind turbine blades, fuel cells, and solar panels.

- Q: What are the different fiberglass fabric weaves for impact resistance?

- There are several different fiberglass fabric weaves that are known for their impact resistance. Some of the common weaves include plain weave, twill weave, satin weave, and leno weave. Each weave has its own unique characteristics and advantages when it comes to providing impact resistance in fiberglass fabrics.

- Q: Can fiberglass fabric be used for making filters?

- Yes, fiberglass fabric can be used for making filters. Fiberglass fabric is known for its high strength and durability, as well as its ability to withstand high temperatures. These properties make it an excellent choice for filter applications. The fabric can be woven into various shapes and sizes, allowing for customization to meet specific filtration requirements. Additionally, fiberglass fabric has a high resistance to chemicals and corrosion, making it suitable for use in a wide range of industries, including automotive, aerospace, and industrial applications. Overall, fiberglass fabric is a reliable and effective material for making filters.

- Q: How is fiberglass fabric sewn?

- Fiberglass fabric is typically sewn using a heavy-duty sewing machine equipped with a strong needle and thread. The process involves aligning the edges of the fabric panels and feeding them through the machine, allowing the needle to pierce through the fabric layers and create stitches. It is important to use a sharp needle specifically designed for sewing fiberglass fabric, as this material can be tough and abrasive, potentially causing regular needles to break or become dull quickly. Additionally, using a sturdy thread, such as a polyester or nylon thread, is crucial to ensure the durability and longevity of the seams. Sewing fiberglass fabric requires skill and precision, as the material can be slippery and difficult to handle. It is recommended to practice on scrap pieces before attempting to sew large or complex projects.

- Q: How does fiberglass fabric handle repeated flexing and stretching?

- Fiberglass fabric is known for its exceptional durability and ability to withstand repeated flexing and stretching. Due to its inherent flexibility and high tensile strength, fiberglass fabric can handle these mechanical stresses without significant damage or loss of performance. The interwoven fiberglass strands provide the fabric with excellent resistance to compression, bending, and stretching, making it highly suitable for applications that require repetitive motion or dynamic loads. Additionally, the unique properties of fiberglass, such as its low coefficient of thermal expansion and high resistance to chemicals and moisture, further contribute to its ability to handle repeated flexing and stretching. Overall, fiberglass fabric is a reliable and robust material that can withstand the demands of various industries and applications.

- Q: Is fiberglass fabric resistant to salt spray in coastal areas?

- Yes, fiberglass fabric is resistant to salt spray in coastal areas. Fiberglass is well-known for its corrosion resistance and durability, making it an excellent choice for applications in marine environments. Salt spray, which contains corrosive salt particles, can cause damage to many materials over time. However, fiberglass fabric is specifically designed to withstand the harsh conditions of coastal areas, including exposure to salt spray. It does not corrode or deteriorate when exposed to saltwater, making it an ideal choice for various marine applications such as boat covers, sails, and awnings.

- Q: What are the advantages of using fiberglass fabric in construction?

- There are several advantages of using fiberglass fabric in construction. Firstly, fiberglass fabric is incredibly strong and durable, making it an ideal material for reinforcing structures and providing them with enhanced stability. Secondly, fiberglass fabric is lightweight, which makes it easier to transport and handle during construction. Additionally, fiberglass fabric is highly resistant to corrosion, chemicals, and fire, making it a safe and reliable choice for construction projects. Lastly, fiberglass fabric is versatile and can be easily molded into different shapes and sizes, allowing for greater design flexibility in construction.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Fabrics Reinforced with High Quality Aluminium Foil

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords