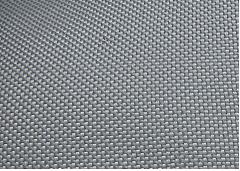

Biaxial Fiberglass Fabric for Surfboard

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Fabrics for surfboard:

The Fiberglass Fabrics for surfboard is a kind of alkali-free glass fiber fabrics produced by utilizing abroad advanced technology and equipment. By means of a surface treatment it has excellent electro-insulation property and workability. It is used mainly in printed circuit boards, and is also used as base materials for computers and home electro-devices.

The Fiberglass Fabrics for surfboard is weaved of high quality C-glass fibers or E-glass fibers.

The excellent properties of Fiberglass Fabrics for surfboard:

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of Fiberglass Fabrics for surfboard:

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

Packing of Fiberglass Fabrics for surfboard:

The Fiberglass fabric for surfboard is wrapped on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

- Q: Can fiberglass fabric be used for reinforcing concrete?

- Yes, fiberglass fabric can be used for reinforcing concrete. Fiberglass fabric is a lightweight and strong material made from fine glass fibers. It is commonly used as a reinforcement material in various industries, including construction. When used in concrete reinforcement, fiberglass fabric helps to improve the tensile strength and durability of the concrete structure. Fiberglass fabric is particularly beneficial in concrete reinforcement due to its high strength-to-weight ratio. It provides excellent resistance to corrosion, chemical attack, and weathering, making it suitable for both interior and exterior applications. Additionally, fiberglass fabric is non-magnetic and non-conductive, making it a preferred choice in areas where electromagnetic interference or conductivity is a concern. The process of using fiberglass fabric for reinforcing concrete involves laying the fabric in between the layers of wet concrete during the construction process. The fabric acts as a reinforcement, distributing the tensile stresses across the entire concrete structure, thus increasing its overall strength and preventing cracks or fractures. Furthermore, fiberglass fabric is relatively easy to handle and install. It can be cut into different shapes and sizes to fit specific reinforcement requirements. The fabric can also be easily molded or wrapped around complex shapes, allowing for versatile use in various concrete structures such as beams, columns, walls, and slabs. Overall, fiberglass fabric is a reliable and effective material for reinforcing concrete. It offers numerous advantages, including high strength, resistance to corrosion, and ease of installation. Its use in concrete reinforcement helps to enhance the structural integrity and longevity of the concrete, making it a popular choice in the construction industry.

- Q: Can fiberglass fabric be used for reinforcement in 3D printing?

- Indeed, reinforcement in 3D printing can be achieved through the utilization of fiberglass fabric. This material, known for its strength and lightweight nature, presents an excellent option for providing additional structural support to objects produced via 3D printing technology. It effectively reinforces specific areas of a print, such as corners or joints, thereby safeguarding against potential cracking or breaking. The incorporation of layers of fiberglass fabric within the 3D printed object significantly enhances its overall strength and durability. Nevertheless, it is crucial to acknowledge that employing fiberglass fabric in 3D printing necessitates the use of specialized equipment and techniques to ensure proper adhesion and integration with the printed material.

- Q: What are the safety precautions when working with fiberglass fabric?

- When working with fiberglass fabric, it is important to take certain safety precautions to protect yourself from potential hazards. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including goggles or safety glasses, a respirator or mask, gloves, and protective clothing. This will help minimize the risk of inhaling fiberglass particles, getting them in your eyes, or having direct skin contact. 2. Ventilation: Ensure that the work area is well-ventilated to prevent the accumulation of fiberglass dust or fumes. If working indoors, use exhaust fans or open windows to promote airflow and remove any airborne particles. 3. Dust Control: Minimize the generation of fiberglass dust by using wet methods, such as wetting the fabric before cutting or using a water mist to control airborne particles. Consider using a dust collection system or vacuum with a HEPA filter to capture any fiberglass dust that may be produced. 4. Cutting and Handling: When cutting fiberglass fabric, use appropriate tools such as shears or a rotary cutter to avoid fraying. Handle the fabric carefully to prevent the release of loose fibers into the air. If possible, use pre-cut fiberglass pieces to minimize the need for cutting on-site. 5. Cleanup: After completing the work, clean up any fiberglass dust or debris using a vacuum cleaner with a HEPA filter. Avoid using compressed air or brooms, as they can disperse the particles into the air. Dispose of any waste material in accordance with local regulations. 6. Hygiene: Practice good personal hygiene by washing your hands and face thoroughly after working with fiberglass fabric. Launder any contaminated clothing separately to avoid cross-contamination. 7. Training: Ensure that all individuals working with fiberglass fabric are properly trained on the potential hazards, safety procedures, and the correct use of PPE. Regularly review and update safety protocols to promote a safe working environment. By following these safety precautions, you can minimize the risks associated with working with fiberglass fabric and protect your health and well-being.

- Q: Can fiberglass fabric be used for heat-resistant aprons?

- Yes, fiberglass fabric can be used for heat-resistant aprons.

- Q: Can fiberglass fabric be used for insulation in cold storage facilities?

- Certainly, cold storage facilities can utilize fiberglass fabric as insulation. Renowned for its remarkable thermal insulation properties, fiberglass fabric proves to be a perfect selection for insulating cold storage facilities. It exhibits utmost effectiveness in impeding heat transfer, thereby aiding in maintaining the desired temperature within the facility. Furthermore, fiberglass fabric showcases resilience against moisture, mold, and mildew, prevailing issues in cold storage environments. This renders it an enduring and enduring option for insulation. Additionally, fiberglass fabric boasts effortless installation and adaptability to accommodate diverse shapes and sizes, guaranteeing comprehensive coverage and insulation throughout the facility.

- Q: Is fiberglass fabric resistant to staining?

- Yes, fiberglass fabric is generally resistant to staining. The material is made from fine fibers of glass, which are woven together to create a strong and durable fabric. Fiberglass fabric is known for its non-porous nature, which means that it does not easily absorb liquids or substances that could cause staining. This makes it highly resistant to most stains, including those caused by common household items such as food, beverages, oil, and grease. Additionally, fiberglass fabric is often treated with a protective coating or finish, further enhancing its stain-resistant properties. However, it is important to note that while fiberglass fabric is resistant to staining, it is not completely immune to all types of stains. Some particularly stubborn or harsh substances, such as certain chemicals or dyes, may be able to cause discoloration or staining on fiberglass fabric. Therefore, it is always advisable to promptly clean any spills or stains on fiberglass fabric to ensure its long-term durability and appearance.

- Q: Is fiberglass fabric suitable for use in architectural membranes?

- Yes, fiberglass fabric is suitable for use in architectural membranes. Fiberglass is a versatile and durable material that offers numerous benefits for architectural applications. It is lightweight, yet strong, providing excellent structural support for membrane structures. Fiberglass fabric is also resistant to UV radiation, chemicals, and weathering, ensuring long-lasting performance and durability. Moreover, fiberglass fabric can be easily manipulated and shaped to fit different architectural designs, making it highly adaptable for various structures, such as roofs, canopies, and facades. It also offers a high degree of translucency, allowing natural light to filter through, creating a visually appealing and energy-efficient environment. Additionally, fiberglass fabric is fire-resistant, making it a safe choice for architectural membranes. It also has low maintenance requirements, reducing the need for frequent repairs or replacements. Overall, fiberglass fabric is a suitable material for architectural membranes due to its strength, durability, versatility, and other beneficial properties, making it an ideal choice for architects and designers seeking innovative and reliable solutions for their projects.

- Q: What is the typical lead time for ordering fiberglass fabrics?

- The typical lead time for ordering fiberglass fabrics can vary depending on the supplier and the specific product. However, it is common to expect lead times ranging from a few days to a couple of weeks. It is advisable to contact the supplier directly to get an accurate estimate for the particular fiberglass fabric being ordered.

- Q: Can fiberglass fabric be used for making insulation blankets?

- Indeed, insulation blankets can be manufactured using fiberglass fabric. Renowned for its remarkable thermal insulation qualities, fiberglass fabric proves to be a perfect material for crafting insulation blankets. These blankets are specifically engineered to confine heat and hinder its transmission, ensuring efficient insulation across diverse contexts like residential abodes, industrial environments, as well as aerospace and automotive sectors. Typically, the fiberglass fabric employed in insulation blankets is woven or knitted, rendering it supple and effortlessly modifiable to suit various shapes and dimensions. Moreover, fiberglass fabric exhibits traits of being lightweight, fireproof, and resistant to both chemicals and moisture, thereby establishing itself as a dependable option for insulation purposes.

- Q: What is an electroplated glass fabric?

- The main strength of cloth on the latitude and longitude direction of fabric, weft or warp for high strength occasions, can also be woven into unidirectional cloth, it can be more roving to warp or weft arrangement, single warp and single weft cloth to cloth. The roving roving is made up of parallel filaments or parallel filaments. According to the composition of glass, roving can be divided into E-GLASS alkali free glass roving and alkali glass roving in C-GLASS.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Biaxial Fiberglass Fabric for Surfboard

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords