Fiberglass Over Fabric Silica Glass Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Vermiculite coated silica Fiberglass cloth is high-temperature resistant products, made by silica glass fiber cloth coat with vermiculite.

Application:

Widely use as heat resistant and ablation-resistant material for rocket, missile and space vehicle;

High-temperature resistant, thermal insulation, refractory material;

Dust collect for high temperature gas;

Liquid filtration & Sound absorbing and thermal insulation for vehicle, motor bicycle;

The thermal insulation protective materials for molten liquid filtration.

Product Capability:

Higher temperature resistant, higher thermal insulation, low thermal conductivity;

Thermal stability and chemical stability;

Good dielectric performance;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

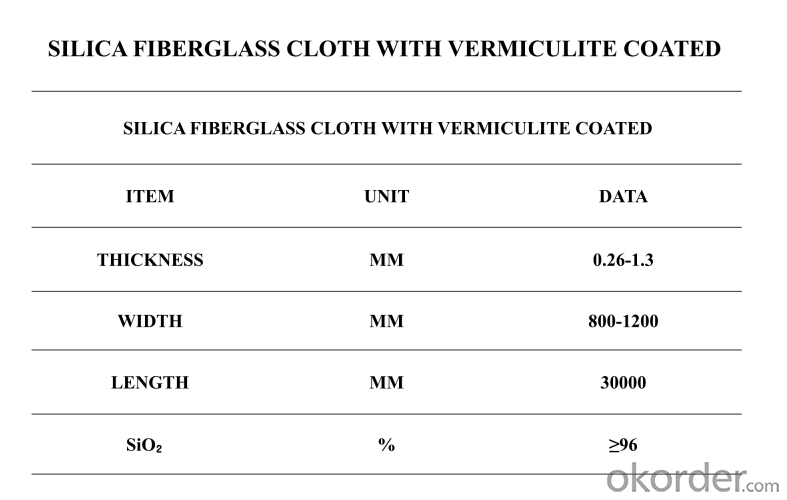

Data Sheet:

Silica fiber products: A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q: Can fiberglass fabric be used for heat-resistant sleeves?

- Indeed, heat-resistant sleeves can be made using fiberglass fabric. The properties of fiberglass fabric make it an excellent choice for heat-resistant applications. It can withstand high temperatures without melting or deforming, thanks to its outstanding heat-resistant capabilities. With a high melting point and resistance to fire, fiberglass fabric is the ideal material to protect against heat. Industries that require heat protection, such as welding, metalworking, and firefighting, often favor fiberglass fabric for its ability to insulate and create a barrier between the user and hot surfaces. Moreover, fiberglass fabric offers additional benefits, including being lightweight, durable, and flexible. These qualities ensure ease of movement and comfort while providing effective heat protection.

- Q: Can fiberglass fabric be used for making insulation boards?

- Yes, fiberglass fabric can be used for making insulation boards. It is a common material choice due to its excellent thermal insulation properties and fire resistance. The fabric is typically combined with other materials and processed into insulation boards to enhance their energy-saving capabilities and provide effective heat insulation.

- Q: How does fiberglass fabric perform in terms of tensile strength?

- Fiberglass fabric has gained a reputation for its extraordinary tensile strength, positioning it as one of the most robust and durable materials on the market. By interweaving delicate glass fibers, a resilient and sturdy fabric is created, capable of enduring significant tension without breaking or stretching. The tensile strength of this fabric is typically measured in pounds per square inch (psi) or newtons per square meter (N/m2), consistently surpassing the strength of commonly utilized materials like cotton or polyester. This exceptional tensile strength renders fiberglass fabric suitable for a diverse range of applications, including construction, industry, automotive, and even aerospace. In summary, fiberglass fabric's remarkable performance in terms of tensile strength guarantees reliable and enduring solutions across various industries.

- Q: How does fiberglass fabric perform in chemical environments?

- Fiberglass fabric is known for its excellent performance in chemical environments. It is highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and oils. The fabric's ability to withstand chemical exposure is primarily due to its composition, which consists of glass fibers that are coated or impregnated with a chemical-resistant resin. The chemical resistance of fiberglass fabric makes it an ideal choice for various applications in industries such as chemical processing, petrochemical, pharmaceutical, and food processing. It can be used in the form of curtains, gaskets, seals, and linings to protect equipment and structures from corrosive chemicals. Furthermore, fiberglass fabric's resistance to chemical exposure also extends to high temperatures. It can withstand continuous operating temperatures of up to 550°C (1022°F) without significant degradation. This property makes it suitable for applications that involve both high-temperature and chemical environments, such as thermal insulation and fire protection systems. In addition to its chemical resistance, fiberglass fabric also offers other beneficial properties. It is lightweight, durable, and has excellent mechanical strength. It is also non-flammable, providing an added layer of safety in chemical environments where fire hazards are a concern. Despite its exceptional performance in chemical environments, it is important to note that fiberglass fabric may still be susceptible to certain highly reactive chemicals or extreme conditions. Therefore, it is crucial to consult with manufacturers or experts to determine the suitability of fiberglass fabric for specific chemical environments and applications.

- Q: Is fiberglass fabric resistant to chemicals in oil and gas industry?

- Indeed, in the realm of the oil and gas industry, chemicals pose no threat to fiberglass fabric. Renowned for its extraordinary chemical resistance qualities, fiberglass fabric proves to be apt for a multitude of industrial uses, particularly within the oil and gas sector. Its resistance spans across a broad spectrum of chemicals, encompassing acids, alkalis, solvents, and hydrocarbons, which are frequently encountered in this industry. Furthermore, fiberglass fabric also demonstrates resistance against elevated temperatures, fire, and UV radiation, thereby establishing itself as a resilient and dependable material option for deployment in this field.

- Q: Can fiberglass fabric be used for making clothing?

- Clothing production with fiberglass fabric is feasible, although it is not widely adopted in the fashion industry. Fiberglass fabric is renowned for its durability, strength, and ability to resist high temperatures. It finds common usage in insulation, fireproofing, and protective gear within industrial settings. However, its qualities render it an unpopular option for clothing. The stiffness of fiberglass fabric, along with its potential to cause itchiness and discomfort against the skin, discourages its use. Moreover, the fabric lacks breathability, leading to excessive perspiration. Additionally, its inflexibility and poor draping properties make it challenging to create well-fitted and mobile garments. Hence, although technically viable, the fashion industry rarely employs fiberglass fabric for clothing production.

- Q: Can fiberglass fabrics be used for automotive applications?

- Yes, fiberglass fabrics can be used for automotive applications. They are commonly used for making car body parts, such as hoods, fenders, and panels, as well as for reinforcing and strengthening various automotive components. Fiberglass fabrics offer excellent strength-to-weight ratio, durability, and resistance to corrosion and chemicals, making them suitable for automotive use.

- Q: What is the difference between woven and non-woven fiberglass fabric?

- Woven and non-woven fiberglass fabrics share a common origin in fiberglass fibers, yet they vary in terms of their construction and characteristics. Woven fiberglass fabric is produced by interlacing individual fiberglass strands in a crosshatch pattern to create a resilient and robust fabric. This weaving process yields a fabric with a consistent and uniform appearance akin to conventional textiles. Woven fiberglass fabrics are recognized for their durability, pliability, and exceptional dimensional stability. They are commonly employed in applications that necessitate high tensile strength, such as reinforcing materials for composite structures, boat construction, the aerospace industry, and automotive components. Conversely, non-woven fiberglass fabric is fashioned by fusing or matting the fiberglass fibers together using diverse techniques, such as needle punching or chemical bonding. Unlike woven fabrics, non-woven fiberglass fabrics lack a regular weave pattern and may exhibit a more arbitrary fiber orientation. This construction method confers distinct properties upon non-woven fiberglass fabrics, including high absorbency, thermal insulation, and filtration capabilities. Due to their structure, non-woven fiberglass fabrics are frequently utilized in insulation materials, filtration media, soundproofing, and as roofing material reinforcement. In essence, the primary distinction between woven and non-woven fiberglass fabrics resides in their construction and resultant properties. Woven fabrics provide strength, stability, and flexibility, rendering them suitable for structural applications, whereas non-woven fabrics deliver absorbency, insulation, and filtration properties, making them ideal for applications that necessitate these specific characteristics.

- Q: Is fiberglass fabric resistant to pests in agricultural settings?

- In agricultural settings, fiberglass fabric exhibits resistance against pests. It is unappealing to insects, rodents, and birds due to its composition. Its sleek and impermeable surface poses challenges for pests in search of sustenance, refuge, or materials for nesting. Consequently, they are deterred from inhabiting or causing harm to the fabric. Moreover, fiberglass fabric does not succumb easily to rot, decay, or moisture absorption, thereby minimizing the probability of pest infestation. This renders it a highly favorable option for agricultural environments that prioritize pest management to safeguard crops and uphold a sound ecosystem.

- Q: Can fiberglass fabric be used for making window screens?

- Yes, fiberglass fabric can be used for making window screens. Fiberglass is a lightweight and durable material that is resistant to tears, corrosion, and UV rays, making it an ideal choice for window screens. It is also highly flexible, allowing for easy installation and removal. Additionally, fiberglass fabric has a fine mesh structure that effectively keeps out insects while still allowing for airflow and visibility. Overall, fiberglass fabric is a popular and reliable option for making window screens.

Send your message to us

Fiberglass Over Fabric Silica Glass Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords