Fiberglass Mat Tissue Woven Roving Combo Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

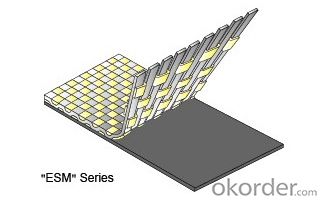

1.Brief Introduction

E-Glass Woven Roving Combo Mat is a complex mat made by stitching together woven roving and a layer of distributed chopped strand. Its main specification is woven roving (300g/m2~900g/m2) with chopped strands (50g/m2~500g/m2)。 The product has a maximum width of 110 inches. This product can be used for boat manufacturing.

2.Product Structure

3.Product Specifications

Product No | Overall Density | Woven Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | |

ESM1808 | 896.14 | 612 | 274.64 | 9.5 |

ESM1810 | 926.65 | 612 | 305.15 | 9.5 |

ESM1815 | 1080.44 | 612 | 457.73 | 10.71 |

ESM2408 | 1132.35 | 847 | 274.64 | 10.71 |

ESM2410 | 1162.86 | 847 | 305.15 | 10.71 |

ESM2415 | 1315.44 | 847 | 457.73 | 10.71 |

EMC2430 | 1762.71 | 847 | 900 | 15.71 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What is the expected lifespan of fiberglass mat tissue?

- The expected lifespan of fiberglass mat tissue can vary depending on several factors such as the quality of the material, the conditions it is exposed to, and the specific application it is used for. However, on average, fiberglass mat tissue is known for its durability and long lifespan. When properly manufactured and installed, fiberglass mat tissue can last for several decades. It is resistant to rot, corrosion, and many chemicals, making it suitable for various industries and applications. Additionally, fiberglass mat tissue is known for its strength and ability to withstand high temperatures. However, it is important to note that exposure to harsh environmental conditions, such as extreme temperatures, UV radiation, and moisture, can potentially degrade the material over time. Regular maintenance and proper care can help extend the lifespan of fiberglass mat tissue. Overall, while it is challenging to determine an exact expected lifespan for fiberglass mat tissue, it is generally considered to be a long-lasting material when used and maintained correctly.

- Q: Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Indeed, insulation in chemical storage tanks can be achieved using fiberglass mat tissue. The exceptional insulation properties of fiberglass render it a fitting substance for tanks that house chemicals. Typically composed of finely interwoven glass fibers, the fiberglass mat tissue constitutes a robust and long-lasting material. Its application to the inner walls of the tank effectively insulates and thwarts heat transfer. Furthermore, fiberglass exhibits corrosion resistance and can endure the detrimental effects of the chemicals commonly stored within these tanks, making it an optimal option for insulation in chemical storage tanks.

- Q: How does fiberglass mat tissue perform in terms of heat insulation?

- Fiberglass mat tissue exhibits a relatively satisfactory performance when it comes to heat insulation. Its composition, consisting of delicate glass fibers and a bonding agent, grants it commendable thermal resistance properties. These fibers effectively capture pockets of air, which function as thermal barriers by diminishing heat transfer. Consequently, fiberglass mat tissue emerges as an appropriate insulation material for a diverse range of applications, including the construction industry, where it is employed to insulate walls, roofs, and attics. Furthermore, fiberglass mat tissue finds extensive use in the automotive and aerospace sectors to insulate engine compartments and curtail heat transfer through vehicle panels, respectively. Nevertheless, it is worth noting that although fiberglass mat tissue offers exceptional thermal insulation, it may not be as efficient as alternative insulation materials like foam or mineral wool, which possess higher thermal resistance values. Ultimately, the suitability of fiberglass mat tissue as an insulation material hinges upon the specific requirements of the project at hand.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: Can fiberglass mat tissue be used for automotive applications?

- Yes, fiberglass mat tissue can be used for automotive applications. Fiberglass mat tissue is a versatile material that is commonly used in the automotive industry for various purposes. It is often used as a reinforcement material in composite parts, such as bumpers, body panels, and interior components. The high strength and lightweight properties of fiberglass mat tissue make it an ideal choice for automotive applications, as it helps to enhance the overall performance and durability of the vehicle. Additionally, fiberglass mat tissue can also provide excellent sound insulation and vibration damping properties, which are crucial for improving the comfort and noise reduction in automobiles. Overall, fiberglass mat tissue is a reliable and widely used material in the automotive industry, contributing to the production of high-quality and efficient vehicles.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Certainly! Fiberglass mat tissue is applicable for insulation purposes in hot climates. Fiberglass possesses remarkable thermal insulation characteristics that render it suitable for both cold and hot environments. In hot climates, fiberglass insulation effectively impedes the transmission of heat from the external to the internal areas of a structure, thereby ensuring a pleasant indoor temperature. It functions as a shield by minimizing the conduction, convection, and radiation of heat. Moreover, fiberglass insulation exhibits fire resistance, durability, and non-absorbency, thus establishing itself as an optimal option for insulation in hot climates.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Fiberglass mat tissue can indeed be used for insulation in cleanrooms. It offers several advantages that make it a suitable choice for such applications. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which helps to maintain the desired temperature and prevent heat transfer in cleanrooms. This is crucial in environments where temperature control is essential for processes or equipment. Additionally, fiberglass mat tissue has good acoustic insulation capabilities, which can help in reducing noise levels within cleanrooms. This is particularly important in cleanrooms where sensitive equipment or experiments are conducted, as minimizing noise disturbances can ensure accurate and reliable results. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not catch fire easily. This adds an extra layer of safety in cleanrooms where flammable materials or volatile substances may be present. The non-combustible nature of fiberglass mat tissue also contributes to its overall durability and longevity. Lastly, fiberglass mat tissue is resistant to moisture, making it suitable for cleanrooms where humidity control is crucial. It does not absorb moisture, preventing the growth of mold or mildew, which can be detrimental to cleanroom environments. Overall, fiberglass mat tissue is a viable option for insulation in cleanrooms due to its thermal and acoustic insulation properties, non-combustible nature, and resistance to moisture. Its use can contribute to maintaining the desired conditions within cleanrooms and ensuring the integrity of processes and equipment.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Fiberglass mat tissue is indeed suitable for the construction of boat hulls. This lightweight and robust material is widely employed in the boat-building and repairing industry. By combining fiberglass strands with a binder, a flexible mat is formed, allowing for easy shaping and molding into various forms. Boat hulls necessitate a sturdy, water-resistant material with excellent structural integrity, all of which fiberglass mat tissue offers. Moreover, this material is relatively easy to manipulate and can be layered to enhance its strength according to requirements. Consequently, it is a favored option for constructing boat hulls.

- Q: What are the advantages of using fiberglass mat tissue in construction?

- There are several advantages of using fiberglass mat tissue in construction. Firstly, it provides excellent strength and durability, making it highly resistant to impacts and weather conditions. Additionally, it has a high tensile strength, allowing it to withstand heavy loads without deformation. Fiberglass mat tissue is also lightweight, making it easier to handle and transport. Moreover, it is non-combustible and provides good thermal insulation properties, enhancing the overall safety and energy efficiency of the construction. Lastly, fiberglass mat tissue is cost-effective, as it requires minimal maintenance and has a long lifespan, reducing the need for frequent replacements.

- Q: Can fiberglass mat tissue be used for insulation in power generation facilities?

- Certainly, insulation in power generation facilities can make use of fiberglass mat tissue. This versatile material is frequently employed for insulation due to its exceptional properties in thermal and electrical insulation. With resistance to high temperatures, it effectively captures and hinders heat transfer, thus making it highly suitable for power generation facilities where heat management is vital. Moreover, fiberglass mat tissue is lightweight, easily installed, and provides durability and longevity, rendering it a cost-effective option for insulation in such facilities.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords