Self-Adhesive Fiberglass Mesh Fabric - High Quality Warp Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

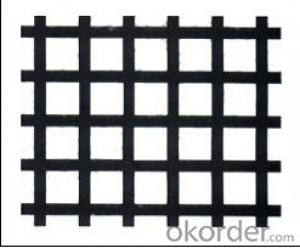

Warp Knitting Polyester geogrid

The Warp Knitting Polyester geogrid selects the excel in synthetic fiber as a raw material,uses the warp knitting oriented structure,latitude and longitude in the fabric to the yarn between not curving condition,the intersection unifies mutually with the excel in textile fiber filament bundle,forms the reliable combining site,displays its mechanical properties fully.

Product Function

2.Characteristics

1. Each kind of higher Uygur path,railroad’s soft roadbed enhancement isolation different base earth material.

2. The river bank,the slope of embankment strengthen stably.

3. Each kind of ground strengthens stably.

4. Strengthens the bridge connection surface.

3.Application

1. Geogrid width ranging from 1000mm to 6000mm

2. High intensity, high module, low slow change ,anti-aging , anti-embrittlement, tensile strength to be high strength.

3. High anti-peel strength ,with the soil crushed stone binding force strong and may pre-design many kinds of characteristics.

4.FAQ

Product No. | Stretching ratio(%) | Grid(mm) | Width(mm) | ||

Vertical | Horizontal | ||||

PET20-20 | 13 | 20 | 20 | 12.7x12.7 25.4x25.4 | ±5 |

PET30-30 | 13 | 30 | 30 | 12.7x12.7 25.4x25.4 | ±5 |

PET40-40 | 13 | 40 | 40 | 12.7x12.7 25.4x25.4 | ±5 |

PET50-50 | 13 | 50 | 50 | 12.7x12.7 25.4x25.4 | ±5 |

PET80-80 | 13 | 80 | 80 | 12.7x12.7 25.4x25.4 | ±5 |

PET100-100 | 13 | 100 | 100 | 12.7x12.7 25.4x25.4 | ±5 |

PET120-120 | 13 | 120 | 120 | 12.7x12.7 25.4x25.4 | ±5 |

Note: The Warp Knitting Polyestergeogrid are available with a width range of 1000mm~6000mm.Other specifications are also available on customer request.

- Q: How does fiberglass fabric handle oil and grease?

- Fiberglass fabric is highly resistant to oil and grease. It does not absorb them easily, making it an ideal material for use in environments where oil and grease are present. The smooth surface of fiberglass fabric allows oil and grease to be easily wiped off, ensuring its durability and longevity.

- Q: Can fiberglass fabric be used for making curtains or dividers?

- Fiberglass fabric is capable of being utilized in the creation of curtains or dividers. Its reputation lies in its durability, strength, and fire resistance, rendering it an appropriate material for these purposes. Additionally, it possesses a lightweight and flexible nature, facilitating effortless manipulation and installation. Furthermore, fiberglass fabric boasts easy cleaning and maintenance, making it a practical selection for curtains or dividers across diverse settings, including homes, offices, and industrial spaces.

- Q: Roof with a single group of waterproof coating and glass fiber cloth done, but the past is still in the seam water seepage, how should remediation?

- Now there are waterproof paint, not black, black is likely to be asphalt type, easy to brittle crackingNow there are chlorinated rubber class waterproof, and silicone waterproof, you buy when asked clearly type, and then mixed white cement modulation, brush more than a few times, anti cracking, waterproof prominent, can be directly built

- Q: How is fiberglass fabric dyed or colored?

- Fiberglass fabric can be dyed or colored using a variety of methods. One common technique is to use a process called solution dyeing, where the color is added to the raw materials before they are spun into fibers. This ensures that the color is evenly distributed throughout the fabric and is resistant to fading or washing out. Another method is to apply the color to the fabric after it has been woven or knitted. This can be done through a process called piece dyeing, where the entire fabric is immersed in a dye bath and then washed and dried. Alternatively, the color can be applied using a printing technique, where a design or pattern is transferred onto the fabric using colored inks. In some cases, fiberglass fabric can also be colored through a post-treatment process. This involves applying a color coating or pigment to the surface of the fabric, which can enhance its appearance and provide additional protection against UV rays or other environmental factors. It is important to note that the specific method used to dye or color fiberglass fabric can depend on various factors, including the desired color, the type of fabric, and the intended application. Additionally, certain dyes or pigments may be more suitable for fiberglass fabric than others, depending on their compatibility and resistance to chemicals or heat. Therefore, it is crucial to consult with experts or manufacturers to determine the best coloring method for a particular fiberglass fabric project.

- Q: Can fiberglass fabric be used for seals?

- Yes, fiberglass fabric can be used for seals.

- Q: Directions for use of polyester fiberglass fabrics

- We must be careful in handling polyester fiber cloth. If the cloth roll to drop down from the vehicle, will damage the polyester fiber, resulting in practical problems.That if there is a fringe installation, in any direction on the pavement is greater than 2.5 cm stripes must be cut and stacked together, and the hand will overlap in the asphalt layer. At the immersion in polyester fiber cloth must use roller or brush, to ensure that it is with the road full contact and remove bubbles. The width of hot asphalt must be coated polyester fiber cloth width plus 4 inches. The polyester fiber cloth to curve surface is not easy to bend or stretch. The installation on the surface can be truncated cloth, can be mechanically or manually installed.For the polyester fiber cloth can be used when installing a tractor or truck drag with metal roller mechanism, the metal roller is to ensure the preparation of polyester glass fiber cloth spread on the road. In the installation and must be installed behind a row of brush, which will be pressed in the polyester fiber asphalt coating. We must ensure that in the length direction a 5.1 cm composite layer joint polyester fiber cloth in the width direction in a layer 10.2 cm. Lateral joint top must be along the pavement, all joints must be lapped together.

- Q: What are the different fiberglass fabric finishes for chemical resistance?

- There are several different fiberglass fabric finishes available for chemical resistance, including silicone, PTFE (polytetrafluoroethylene), neoprene, and vinyl. These finishes are applied to the fiberglass fabric to provide a protective barrier against various chemicals, making the fabric suitable for use in industries such as chemical processing, oil and gas, and wastewater treatment. Each finish offers different levels of resistance to specific chemicals, so the choice of finish will depend on the specific needs and requirements of the application.

- Q: How is fiberglass fabric used in the production of aerospace components?

- Fiberglass fabric is extensively used in the production of aerospace components due to its unique properties and advantages. This fabric is made from fine fibers of glass, which are woven together to create a strong and flexible material. One of the primary uses of fiberglass fabric in aerospace production is for the reinforcement of composite materials. Composite materials consist of a combination of fiberglass fabric and a resin matrix, such as epoxy. The fabric is impregnated with the resin, forming a composite structure that is lightweight, yet incredibly strong and durable. This composite material is then used to manufacture various aerospace components like aircraft wings, fuselages, and structural panels. The use of fiberglass fabric in composites offers several benefits. Firstly, it provides excellent strength-to-weight ratio, making the aerospace components lighter without compromising their structural integrity. This reduction in weight enhances fuel efficiency, increases payload capacity, and improves overall performance. Additionally, fiberglass fabric offers high tensile strength, stiffness, and resistance to corrosion, which are crucial properties for aerospace applications. Another way fiberglass fabric is used in aerospace production is for thermal insulation. The fabric is often coated with a heat-resistant material, such as silicone or aluminum, to create insulation blankets. These blankets are used to protect critical components, such as fuel tanks, pipes, and engine compartments, from extreme temperatures. Fiberglass fabric's inherent properties of heat resistance, low thermal conductivity, and fire resistance make it an ideal material for such applications. Furthermore, fiberglass fabric is also used as an electrical insulator in aerospace components. It is commonly employed in the construction of circuit boards, electrical cables, and insulating sleeves. Its non-conductive nature and high dielectric strength help prevent electrical leakage and ensure the safe and reliable operation of aerospace systems. In summary, fiberglass fabric plays a vital role in the production of aerospace components. It is used for reinforcing composite materials, providing thermal insulation, and acting as an electrical insulator. Its lightweight, high strength, corrosion resistance, and thermal insulation properties make it an indispensable material for the aerospace industry, contributing to the advancement of aviation technology.

- Q: What are the different fiberglass fabric finishes for mold resistance?

- There are various fiberglass fabric finishes available that provide mold resistance. These finishes are specifically designed to prevent the growth and proliferation of mold and mildew on the fabric surface. Some of the commonly used finishes include: 1. Anti-microbial finish: This finish contains agents that inhibit the growth of microorganisms, including mold and mildew. It creates a protective barrier on the fabric surface, preventing the attachment and growth of mold spores. 2. Fungicide finish: This finish incorporates fungicidal agents that actively kill mold and mildew. It not only prevents their growth but also eliminates any existing mold spores on the fabric. 3. Biocide finish: Similar to the fungicide finish, this finish uses biocidal agents that are effective against a broader range of microorganisms, including mold. It provides long-lasting protection against mold growth. 4. Moisture-wicking finish: Mold thrives in damp environments, so a moisture-wicking finish is crucial for preventing mold growth. This finish allows moisture to evaporate quickly from the fabric, reducing the conditions required for mold to develop. 5. Water-resistant finish: A water-resistant finish makes the fabric less prone to moisture absorption. By repelling water and preventing it from seeping into the fabric fibers, it minimizes the conditions that support mold growth. 6. UV-resistant finish: Ultraviolet (UV) radiation can contribute to the growth of mold, especially in outdoor applications. A UV-resistant finish protects the fabric from the detrimental effects of UV rays, reducing the risk of mold formation. It is important to note that different fiberglass fabric manufacturers may use their own proprietary finishes or combinations of finishes to achieve mold resistance. Thus, it is recommended to consult with the fabric supplier or manufacturer to determine the specific finishes available and their suitability for a particular application.

- Q: Can fiberglass fabric be used for gaskets?

- Yes, fiberglass fabric can be used for gaskets. Fiberglass fabric is widely used in various industries, including automotive, aerospace, and manufacturing, due to its high strength, durability, and resistance to chemicals and extreme temperatures. These properties make it suitable for gaskets, which are used to prevent leaks or to provide a seal between two surfaces. Fiberglass fabric can be cut and shaped into the desired gasket size and can be further impregnated with adhesives or coatings to enhance its sealing capabilities. Additionally, fiberglass fabric is lightweight and flexible, allowing it to conform to irregular surfaces and provide a tight seal. Overall, fiberglass fabric is a versatile material that can effectively be used for gaskets in a wide range of applications.

Send your message to us

Self-Adhesive Fiberglass Mesh Fabric - High Quality Warp Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords