Fiberglass Fabrics with Thermal Insulation Silicone Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Silicone coated fiberglass fabric is made by special formulated liquid or wet silicone rubber dispersed or calendered into the high quality fiberglass cloth and vulcanized, dried. This finished silicone fabric inherits the fiberglass insulation fabric's properties and also improve its fireproof, hand fabrication, oil and waterproof, abrasion resistance.

Features: Fireproof, Thermal Insulation, Abrasion Resistance, Waterproof

Application: Thermal Insulation Cover, Blanket, Jacket, Cover, Pad, Fabric Expansion Joint, Flexible Connector, Welding Blanket, Fire Blanket, Fireproof Curtain, Smoke Curtain

PRICE: USD3.5 per square meter

UNIT: square meter

MOQ: 500 square meter

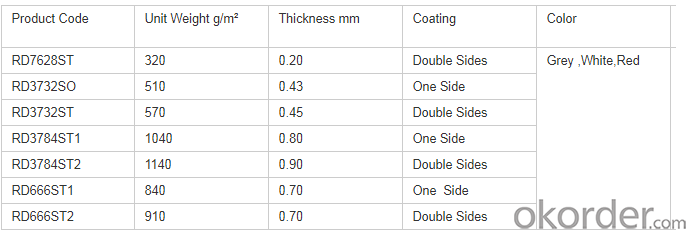

Weight: 140gsm-3000gsm

Width: 90mm to 2000mm or customized

Yarn Type: E-glass

Standing temperature -50℃-550℃

Product name: Silicone Coated Fiberglass Fabric

Coating/Finish/Surface Treatment: Silicone coated

Roll length: 50 meter or customized

Color: Grey, Red, Black, White, Salmon, Green, Blue, Yellow, or customized

Weave Type: Twill, Satin, plain woven or customized

Alkali content: alkali free

Processing service: cutting

Material: fiberglass

Thickness: 0.1mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Fiberglass fabric rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Is fiberglass fabric resistant to fading?

- Yes, fiberglass fabric is resistant to fading. Fiberglass is a synthetic material made from fine fibers of glass, which are highly resistant to fading caused by exposure to sunlight. These fibers are often coated with a protective layer that further enhances their resistance to fading. Additionally, fiberglass fabric is also resistant to many chemicals and does not easily deteriorate over time, making it a durable and long-lasting option for various applications.

- Q: How do fiberglass fabrics perform in terms of breathability?

- Fiberglass fabrics are not known for their breathability. Due to their inherent properties and manufacturing process, fiberglass fabrics tend to have a relatively low level of breathability. The tightly woven nature of fiberglass material restricts the passage of air and moisture through the fabric, resulting in decreased breathability. This lack of breathability can cause discomfort and excessive perspiration when wearing fiberglass fabric in warm or humid environments. However, it is important to note that fiberglass fabrics are primarily used for their durability, strength, and heat resistance, rather than their breathability.

- Q: How does fiberglass fabric handle UV degradation?

- Fiberglass fabric has excellent resistance to UV degradation. The fabric is typically made from glass fibers that are coated with a protective resin, which provides added strength and durability. This resin coating acts as a barrier against the harmful effects of UV radiation from the sun. UV degradation occurs when prolonged exposure to sunlight causes the breakdown of materials, leading to discoloration, weakening, and deterioration. However, fiberglass fabric is known for its exceptional UV resistance, making it highly suitable for outdoor applications. The inherent properties of fiberglass, combined with the resin coating, create a strong protective shield that prevents UV rays from damaging the fabric. This resistance to UV degradation allows fiberglass fabric to maintain its strength, flexibility, and overall integrity even when exposed to harsh sunlight. Furthermore, fiberglass fabric is often used in industries where UV resistance is crucial, such as in the construction of awnings, canopies, and outdoor furniture. It is also commonly utilized in marine applications, where exposure to sunlight and saltwater can be particularly challenging for other materials. In addition to its UV resistance, fiberglass fabric also offers other advantages such as high tensile strength, fire resistance, and chemical resistance. These properties make it a preferred choice in various industries where durability, longevity, and performance are required. Overall, fiberglass fabric is highly effective in handling UV degradation due to its inherent properties and the protective resin coating. Its ability to resist the harmful effects of UV radiation makes it a reliable and durable material for a wide range of applications, both indoors and outdoors.

- Q: How does fiberglass fabric perform in corrosive environments in chemical plants?

- Fiberglass fabric is highly resistant to corrosion and performs exceptionally well in corrosive environments in chemical plants. Its non-reactive nature and excellent chemical resistance make it an ideal choice for protecting equipment and structures from the damaging effects of corrosive substances. Additionally, fiberglass fabric has a high tensile strength and is lightweight, making it easy to install and maintain. Overall, fiberglass fabric offers long-lasting durability and reliability in corrosive environments, ensuring the safety and efficiency of chemical plant operations.

- Q: Are fiberglass fabrics resistant to shrinkage or stretching?

- Fiberglass fabrics are known for their excellent resistance to shrinkage and stretching. Due to the inherent properties of fiberglass, such as its high tensile strength and low elasticity, these fabrics are highly resistant to both shrinkage and stretching. This makes them ideal for applications where dimensional stability is important, such as in the manufacturing of industrial products, insulation materials, and composite materials. Additionally, the durability and resistance to shrinkage and stretching make fiberglass fabrics suitable for high-temperature environments and harsh conditions. Overall, fiberglass fabrics offer excellent stability and maintain their shape and size even when subjected to various external forces.

- Q: Can fiberglass fabric be used for reinforcement in marine applications?

- Marine applications can benefit from the use of fiberglass fabric for reinforcement. This type of fabric is widely chosen for its ability to strengthen and reinforce various parts of boats and other marine structures. Its exceptional strength-to-weight ratio makes it an ideal material for enhancing the structural integrity of marine components. Boats commonly utilize fiberglass fabric to reinforce hulls, decks, bulkheads, and other sections. It is also widely employed in the manufacturing of sailboats, powerboats, yachts, and other watercraft. The fabric can be layered multiple times to provide additional strength and durability. One notable advantage of fiberglass fabric in marine applications is its resistance to water and corrosion. It does not absorb water, making it highly suitable for marine environments where exposure to moisture, saltwater, and other harsh conditions is common. Additionally, fiberglass fabric is resistant to UV radiation, which is crucial for preserving the structural integrity and appearance of marine components. Moreover, fiberglass fabric exhibits excellent dimensional stability, allowing it to retain its shape and strength over time. This attribute is particularly important in marine applications where boats and structures are subject to constant movement, vibrations, and varying loads. In conclusion, fiberglass fabric is a versatile and dependable material for reinforcing marine applications. Its high strength-to-weight ratio, resistance to water and corrosion, and exceptional dimensional stability make it a favored choice among boat builders and marine engineers.

- Q: Is fiberglass fabric suitable for use in medical applications?

- Certain medical applications can benefit from the use of fiberglass fabric. This type of fabric is well-known for its strength, durability, and ability to withstand heat and chemicals. It is a suitable material for a wide range of medical uses. For instance, orthopedic casts, splints, and braces frequently utilize fiberglass fabric due to its excellent support and ability to immobilize injured limbs effectively. Fiberglass fabric is also commonly used in wound dressings and bandages. In these applications, the fabric can be impregnated with antimicrobial substances to prevent infections and promote the healing process. Moreover, fiberglass fabric can be employed in surgical drapes and gowns to create a barrier against fluids and contaminants. However, it is crucial to note that direct contact with open wounds may not be suitable for fiberglass fabric as it can cause irritation and abrasion. Consequently, it is essential to carefully consider the specific application and intended use before incorporating fiberglass fabric into medical settings.

- Q: How is fiberglass fabric used in the environmental industry?

- Due to its unique properties and benefits, fiberglass fabric sees widespread use in the environmental industry for a range of applications. One notable use is in air filtration systems, where the fabric's strength and durability make it an ideal material for manufacturing effective filters that can trap and remove particles, pollutants, and contaminants from the air. Additionally, fiberglass fabric finds application in the construction of wastewater treatment plants and water filtration systems. Its resistance to corrosion, non-reactivity with chemicals, and impressive tensile strength make it suitable for manufacturing pipes, tanks, and other components that are exposed to harsh chemicals or corrosive environments. It is also utilized as a reinforcement material in the construction of water tanks and reservoirs, ensuring their structural integrity and preventing leaks or damages. Furthermore, fiberglass fabric is employed in the environmental industry for the production of geotextiles, which serve various purposes such as erosion control, soil stabilization, and land reclamation. The fabric's high porosity and permeability allow water to pass through while retaining soil particles, effectively preventing erosion and maintaining soil stability. Moreover, fiberglass fabric plays a role in producing insulation materials used in the construction of environmentally friendly buildings and energy-efficient structures. Its excellent thermal insulation properties help reduce energy consumption by preventing heat transfer through walls, roofs, and other building components. In summary, fiberglass fabric is of significant importance in the environmental industry, providing solutions for air and water filtration, erosion control, insulation, and corrosion-resistant infrastructure. Its versatility, durability, and eco-friendly characteristics make it a favored choice for numerous environmental applications.

- Q: How is fiberglass fabric used in the production of geotextiles?

- Fiberglass fabric is used in the production of geotextiles as a reinforcement material. It provides strength and stability to the geotextile, enabling it to withstand high tensile forces and enhance its durability. The fiberglass fabric is typically incorporated into the geotextile through lamination or needle-punching techniques, creating a composite material that can effectively prevent soil erosion, reinforce slopes, and provide separation and filtration functions in various civil engineering applications.

- Q: Can fiberglass fabric be used for making insulation panels?

- Indeed, insulation panels can be produced using fiberglass fabric. Renowned for its outstanding thermal insulation properties, fiberglass fabric is a versatile material extensively utilized in the construction sector for insulation purposes. Its capacity to withstand heat transfer and uphold temperature control renders it a preferred option. By effectively entrapping air and decelerating heat transfer, fiberglass fabric proves to be an impeccable choice for insulation panels. Additionally, its lightweight nature, effortless installation, and long-lasting durability contribute to its widespread preference for diverse insulation applications.

Send your message to us

Fiberglass Fabrics with Thermal Insulation Silicone Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords