Fiber Cement board for villas,high building-010

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

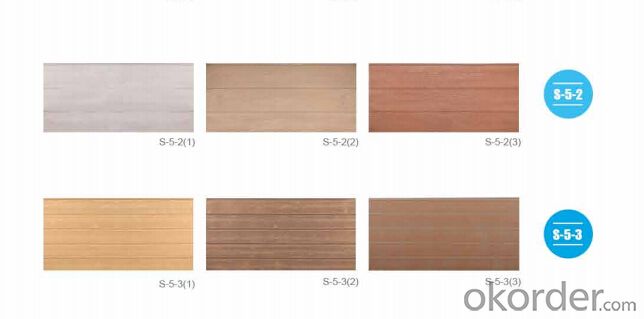

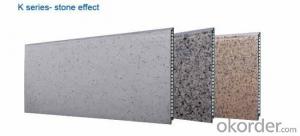

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

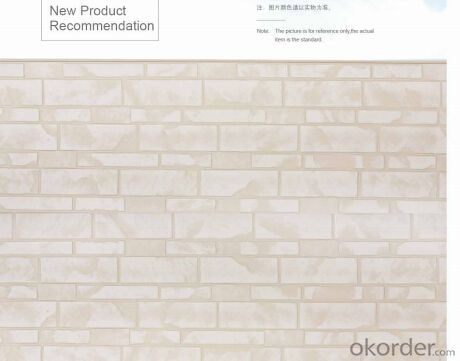

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: Will Titebond II (weatherproof) work? I have a 1928 home and am trying to duplicate one of the original exterior window sills to go on a new window. I need to glue a couple of 5/4 pieces together to get the right thickness and I want it to last. The originals have redwood but it's old growth I believe and more stable than what I can find now in redwood or DF. Correct me if I'm wrong there. Plus I have only two attaching points to work with on either side of the window so I chose the fiber cement product for it's stability. Nothing on James Hardie's site says what can be used to glue it with though.ThanksThanksChris

- I would use gorilla glue which is 100 percent waterproof. or you could use polyurethane caulk which is very tough.

- Q: Gypsum board how to make the effect of cement

- You can paste the wallpaper, you can also let the experienced decoration master to give you the effect.

- Q: Factory roof directly painted on the cement board directly spray the white again

- And other primers completely dry and then spray from the painting should not be much problem. Be careful not to spray too thick.

- Q: Really stone paint the external walls, with ordinary cement board how to deal with the base, what materials to do

- External walls are generally used to deal with putty, specifically including the following steps (the above content are from the general source of paint official website related information):

- Q: My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- Tile council of America calls for a vapor barrier behind the cement board ..The red guard your talking about should and must be used on any horizontal surface in a wet area.. There are other agents like red guard but I v used it many times and had great luck w/ it..Making sure the proper pitch is used for the horizontal surface GL

- Q: The roof of the cement board everywhere cracked, how to do

- At present, the better choice is the polymer waterproofing membrane: waterproof concrete and waterproof mortar two, this waterproof method is simple, easy construction, ordinary masons according to the general plaster construction method can achieve good quality requirements, and low cost , The same waterproof method under the premise of technical level, the overall cost is much lower than the flexible waterproof material for other waterproof materials 1 / 2-1 / 3, the most important thing is safe non-toxic environmental protection, but if the construction process is not good, Cement mortar is likely to crack, repair will be more trouble.

- Q: I need side and rear clearance for a 15 year old wood stove. The 2x4 walls are covered with cement board and ceramic tiles. Behind that is a foundation wall.

- In WA state, with a *certified* wood stove, the clearence is anywhere from 18 to 24 inches. You can put anything non-combustable on that wall... tile, rock, brick, Z brick, or metal plating with 1 air space from backer board. You could always check with the court house to find out what your local building codes are.

- Q: How much is the cement board?

- 65 yuan a, one is 2.4 * 1.2 specifications, 22.5 yuan a square meter. The advantage is not afraid of water (compared with gypsum board), the disadvantage is fragile

- Q: What is the best thing to do with the top floor of the house?

- Wash the trough with a brush with water Will cf-2000 efficient composite waterproofing agent, live putty-like, with water plugging is to be slightly harder, and then filled into the chiseled slot. Sealed compaction can be. Fill the groove before filling the water. Can be plugged with water immediately after the operation of water plugging. 30 minutes can be only 2 kg pressure seepage. 24 hours can be resistant to 7 kg pressure seepage.

- Q: what does this mean second phase in two phases material ( first phase is binding cement ) ?

- First consider the term 'phase' as in 'phase change', such as ice melting. It means a particular state of matter, solid or liquid in the melting of ice. However, in an inhomogenous solid material you can have two or more solid phases. For instance, Transite insulation board was made of portland cement and asbestos [not in use much nowadays]. So what you have is some two phase inhomogenous solid consisting of one phase as binder or cement, and the other phase could be a filler, a fiber, or whatever.

Send your message to us

Fiber Cement board for villas,high building-010

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords