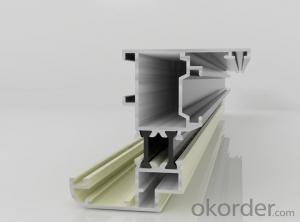

Factory Low Price Extruded Aluminum Heat Sink Profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: How do aluminum profiles provide structural stability?

- Aluminum profiles provide structural stability through their inherent properties such as high strength-to-weight ratio and excellent corrosion resistance. These profiles are designed to distribute and withstand loads efficiently, ensuring the structural integrity of various applications. Additionally, their versatility allows for customization and integration with other materials, further enhancing stability in different environments and industries.

- Q: Can aluminum profiles be used for trade show booths?

- Yes, aluminum profiles can be used for trade show booths. Aluminum profiles are lightweight, durable, and can be easily customized to create various shapes and sizes. They provide a solid framework for constructing trade show booths and offer flexibility in design, allowing for easy assembly, disassembly, and transportation. Additionally, aluminum profiles can be combined with other materials such as fabric, glass, or acrylic panels to create visually appealing and functional trade show booths. Overall, aluminum profiles are a popular choice in the trade show industry due to their versatility, strength, and ease of use.

- Q: Is it possible to utilize aluminum profiles for constructing exterior railings and staircases?

- <p>Yes, aluminum profiles can be used for exterior railings and staircases. They are known for their durability, resistance to corrosion, and low maintenance requirements, making them ideal for outdoor applications. Aluminum's strength and lightweight properties also contribute to its suitability for these structures. However, it's important to ensure that the aluminum is of high quality and properly treated to withstand weather conditions and ensure longevity.</p>

- Q: Do aluminum profiles require any special maintenance?

- There is no need for any special maintenance for aluminum profiles. They are durable and require minimal maintenance, as they are resistant to corrosion, rust, and weathering. Unlike wood or steel, aluminum profiles do not require regular painting, staining, or treatment to maintain their appearance or functionality. Moreover, aluminum is lightweight, making it easy to handle and install. However, it is essential to keep the aluminum profiles clean by regularly using a mild detergent and water solution to remove dirt or debris. This will help to maintain the profiles' aesthetic appeal and ensure their longevity. In summary, aluminum profiles are a convenient and hassle-free choice for various applications, as they do not demand any special maintenance.

- Q: Is aluminum factory harmful to people?

- But most companies now have the ability to avoid these dangers. Only those illegal backward production capacity will do some damage to the environment for money. These national policies, the city firmly banned the shutting down.

- Q: Can aluminum profiles be used in the production of industrial robots?

- Indeed, industrial robots can be manufactured utilizing aluminum profiles. Aluminum, being a lightweight and long-lasting material, presents numerous benefits when constructing robotic systems. Its strength-to-weight ratio is impressively high, rendering it ideal for constructing solid and dependable robot structures. Machining aluminum profiles is a straightforward task, enabling the creation of intricate and precise designs for diverse robot components, including frames, arms, and joints. Furthermore, aluminum's resistance to corrosion proves advantageous in industrial environments where robots may encounter harsh chemicals or challenging surroundings. In summary, aluminum profiles offer a versatile and cost-effective solution for the production of industrial robots.

- Q: Is it possible to use aluminum profiles for outdoor applications like fences and railings?

- <p>Yes, aluminum profiles are commonly used for outdoor applications such as fences and railings. They are favored for their resistance to corrosion, lightweight properties, and durability. Aluminum can withstand harsh weather conditions without rusting, making it an ideal material for outdoor use. Additionally, it is low maintenance, as it does not require painting or frequent repairs. The profiles can be powder-coated or anodized for enhanced protection and aesthetic appeal.</p>

- Q: Can aluminum profiles be used in noise insulation applications?

- Indeed, noise insulation applications can indeed make use of aluminum profiles. These profiles possess remarkable versatility and can be specifically engineered to exhibit exceptional acoustic properties. Consequently, they can serve as the foundation for constructing soundproof windows, doors, walls, and enclosures. By combining aluminum profiles with materials such as acoustic glass, rubber seals, and insulation foam, their noise insulation capabilities can be further enhanced. Moreover, owing to aluminum's inherent strength and durability, it is perfectly suited for deployment in noise insulation applications, as it can withstand the pressures and vibrations generated by sound waves. In summary, aluminum profiles represent a feasible solution for fulfilling noise insulation requirements across various settings, including residential, commercial, and industrial buildings.

- Q: How do you calculate the strength of aluminum profiles?

- To calculate the strength of aluminum profiles, various factors need to be considered. First, the material properties of the aluminum, such as its yield strength and ultimate tensile strength, must be known. Then, the geometric characteristics of the profile, such as its cross-sectional area and moment of inertia, are used in relevant equations to determine the bending, shear, and axial strength of the profile. Additionally, factors like the loading conditions, support conditions, and safety factors are taken into account to ensure the calculated strength is reliable and safe.

- Q: How do aluminum profiles perform in terms of magnetic properties?

- Aluminum profiles do not possess strong magnetic properties. Aluminum is considered non-magnetic as it is not attracted to magnets. This is due to its atomic structure, which does not facilitate the alignment of magnetic domains necessary for magnetic attraction. Therefore, aluminum profiles are generally not affected by magnetic fields and do not have any significant magnetic properties.

Send your message to us

Factory Low Price Extruded Aluminum Heat Sink Profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords