Mill Finished Extruded Aluminum Heat Sink Profiles - Aluminum Profile Extrusion for Sale

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminum Profile Extrusion for Sale China Supplier

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2. Application of Mill Finished Aluminum Profile Extrusion for Sale China Supplier

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Mill Finished Aluminum Profile Extrusion for Sale China Supplier

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

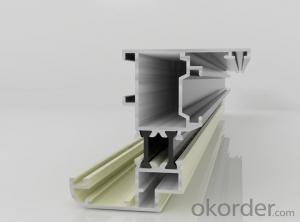

5. Image of Mill Finished Aluminum Profile Extrusion for Sale China Supplier

6. Package and shipping of Mill Finished Aluminum Profile Extrusion for Sale China Supplier

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: I'm made of aluminum, and I need profiles every month. Where can I buy the information and let the factory take the initiative to find me?

- Can go to the Alibaba website, China aluminum network, HC network, China manufacturing network, Mark Polo network, business treasureGlobal hardware networkMusic for hundredChinese supplierChalcoChinese aluminum netGlobal economic and trade networkWeb sites such as the world trade network will be fine,

- Q: How do I choose the right aluminum profile for my project?

- When choosing the right aluminum profile for your project, there are several factors you should consider. Firstly, you need to determine the specific requirements of your project. Consider the purpose and function of the aluminum profile, as well as any specific dimensions or specifications it needs to meet. This will help you narrow down your options and ensure you choose a profile that is suitable for your project. Next, think about the type of aluminum profile that would be most appropriate for your project. There are various types available, such as T-slotted profiles, angle profiles, or channel profiles. Each type has its own advantages and applications, so it's important to understand the differences and select the one that best fits your needs. Consider the strength and durability of the aluminum profile. Evaluate the load-bearing capacity and resistance to corrosion or other environmental factors. Depending on the nature of your project, you may need a profile that can withstand heavy loads or harsh conditions. Another important factor to consider is the compatibility of the aluminum profile with other components or systems. If you plan to use the profile in conjunction with other materials or hardware, ensure they are compatible and can be easily integrated. Additionally, take into account the cost and availability of the aluminum profile. Compare prices from different suppliers and consider the availability of the profile in the required quantity and timeframe. Lastly, it can be beneficial to seek expert advice or consult with professionals who have experience working with aluminum profiles. They can provide valuable insights and recommendations based on their knowledge and expertise. By considering these factors, you can make an informed decision and choose the right aluminum profile that will meet the specific requirements of your project.

- Q: Can aluminum profiles be used for outdoor applications?

- Yes, aluminum profiles can be used for outdoor applications. Aluminum is a highly versatile and durable material that is resistant to corrosion, making it suitable for use in outdoor environments. It has excellent weather resistance and can withstand exposure to sunlight, rain, and temperature variations without deteriorating. Aluminum profiles are commonly used in outdoor applications such as construction, architecture, transportation, and outdoor furniture. They offer strength, stability, and longevity, making them a popular choice for outdoor projects. Additionally, aluminum profiles can be finished with protective coatings or anodized to further enhance their resistance to outdoor elements.

- Q: What is the difference between 6061-T6 and 6063-T6 in aluminum profile?

- Different alloy components determine their mechanical properties differently, and each of the 6061 indexes is much better than 6063

- Q: This question asks for an explanation of various methods used to manufacture aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, but also including casting, rolling, and machining. Extrusion is the most common method, where aluminum is heated and forced through a die to create a desired shape. Casting involves pouring molten aluminum into molds to form specific profiles. Rolling is used to produce flat sheets or plates, which can then be further processed. Machining involves cutting and shaping aluminum using tools like lathes and mills. Other processes include forging, which deforms aluminum under high pressure, and powder metallurgy, where aluminum powder is compacted and sintered into a solid profile. Each process has its advantages and is chosen based on the desired profile shape, strength, and application.</p>

- Q: Can aluminum profiles be used in cleanroom environments?

- Cleanroom environments can indeed utilize aluminum profiles. With its lightweight and adaptable nature, aluminum possesses a multitude of desirable qualities that make it well-suited for cleanroom applications. Being non-corrosive, non-magnetic, and boasting a high strength-to-weight ratio, aluminum is an ideal material for constructing cleanroom structures like walls, partitions, and equipment racks. Moreover, the assembly and disassembly of aluminum profiles are effortlessly accomplished, allowing for flexible cleanroom configurations and future modifications. These profiles can also be seamlessly integrated with other materials such as glass, acrylic, or stainless steel, in order to meet specific cleanroom requirements. Furthermore, aluminum profiles can be enhanced by anodization or coatings to fortify their cleanliness and resistance to contamination. Anodization furnishes a protective layer on the aluminum surface, rendering it more resistant to scratches and wear. Coatings like epoxy or powder coatings can further enhance the profiles' durability and cleanliness. In summary, aluminum profiles offer a multitude of advantages for cleanroom applications, including their lightweight nature, strength, corrosion resistance, and design flexibility.

- Q: How do aluminum profiles perform in terms of dimensional stability?

- Aluminum profiles generally exhibit excellent dimensional stability due to their inherent stiffness and low coefficient of thermal expansion. This means that they maintain their shape and dimensions even under varying temperature conditions, making them suitable for applications where precision and accuracy are crucial.

- Q: This question asks for methods to protect aluminum profiles from corrosion and damage during the processes of transportation and storage.

- <p>To prevent corrosion and damage to aluminum profiles during transportation and storage, follow these guidelines: 1. Keep aluminum profiles dry and clean. Moisture and dirt can accelerate corrosion. 2. Use protective packaging, such as plastic wrap or padded covers, to shield profiles from physical damage and moisture. 3. Store profiles in a cool, dry place away from direct sunlight and corrosive substances. 4. Stack profiles with appropriate padding between layers to prevent scratching. 5. Avoid overloading during transportation and ensure secure fastening to prevent movement and potential damage. 6. Regularly inspect stored profiles for signs of corrosion or damage and address any issues promptly.</p>

- Q: What specific considerations should be taken into account when using aluminum profiles in extreme temperatures, be it cold or hot?

- <p>Aluminum profiles are generally durable and can withstand a wide range of temperatures. However, in extremely cold climates, thermal contraction can occur, potentially leading to gaps or cracks. It's important to allow for expansion and contraction in the design. In hot climates, while aluminum doesn't lose strength, it can expand and warp if not properly supported. Additionally, it can become hot to the touch, which may require protective measures to prevent burns. Always ensure that aluminum profiles are of high quality and are designed for the specific climate conditions they will be exposed to.</p>

- Q: What are the specific requirements or considerations when using aluminum profiles in the construction or design of swimming pools and spas?

- <p>Yes, there are special requirements for using aluminum profiles in swimming pools and spas. These include corrosion resistance to withstand chlorinated water, which is common in pools and spas. Profiles must be made of marine-grade aluminum to prevent rust and ensure longevity. They should also be able to withstand high humidity and temperature fluctuations. Additionally, profiles need to be non-slip and easy to clean to maintain safety and hygiene. The design should also consider structural integrity to support the weight of the pool or spa structure and any associated equipment.</p>

Send your message to us

Mill Finished Extruded Aluminum Heat Sink Profiles - Aluminum Profile Extrusion for Sale

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords