Aluminum Heat Sink Extrusion Profiles for Window and Door with Advantage Price and Free Moulds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Window and Door with Advantage Price and Free Moulds Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Window and Door with Advantage Price and Free Moulds:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

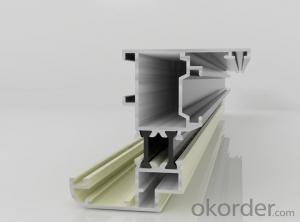

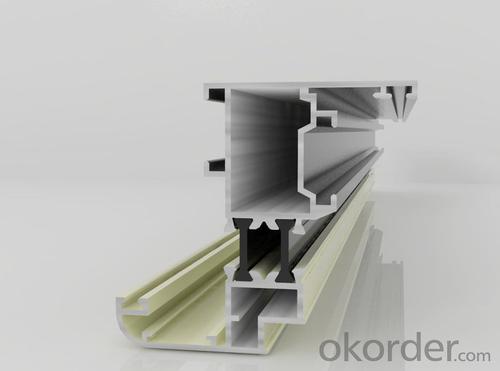

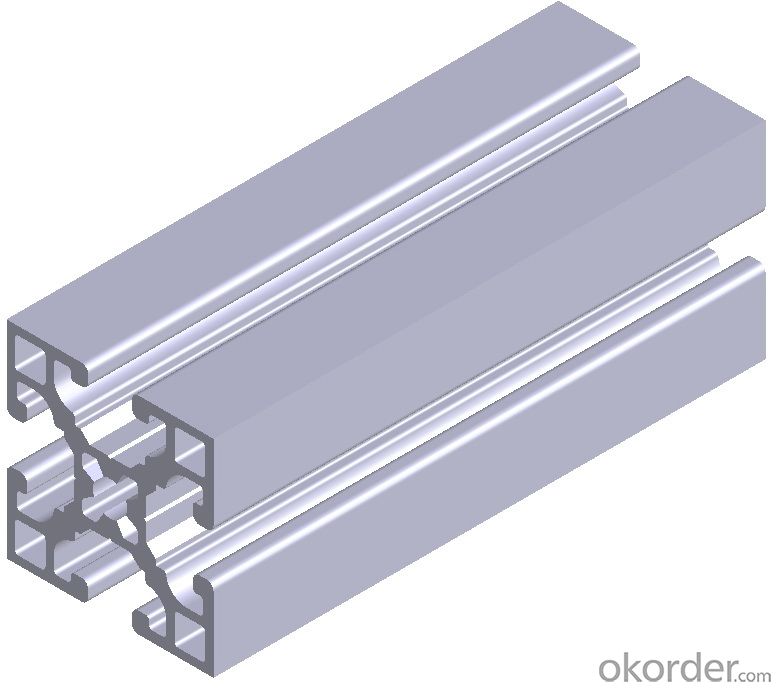

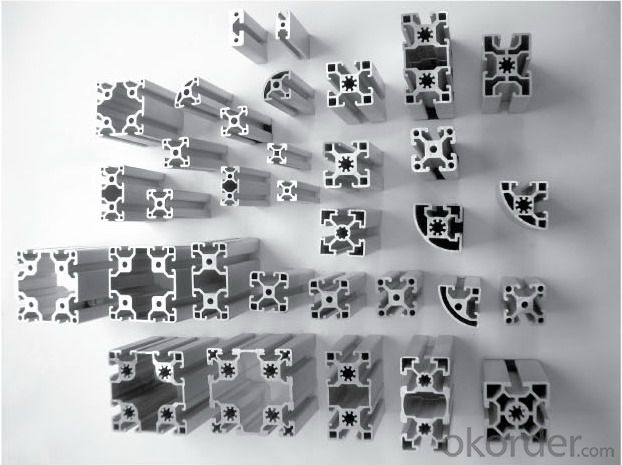

Images of the Aluminium Profile for Window and Door with Advantage Price and Free Moulds:

Aluminium Profile for Window and Door with Advantage Price and Free Moulds Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: What are the fireproofing properties of aluminum profiles?

- Aluminum profiles possess excellent fireproofing properties due to their high melting point, which is around 660 degrees Celsius. This allows them to withstand high temperatures and prevent the spread of fire. Moreover, aluminum does not burn or produce toxic gases when exposed to flames, making it a safe and reliable material for fireproofing applications.

- Q: This question asks for methods to guarantee the high quality of aluminum profiles used in a construction project.

- <p>To ensure high-quality aluminum profiles for your building project, start by selecting profiles from reputable manufacturers known for quality. Check for certifications such as ISO 9001 for quality management systems. Inspect the profiles for uniformity in thickness and color, and ensure they are free from defects like dents or scratches. Request third-party test reports to verify the strength and durability of the profiles. Additionally, consider the chemical composition and alloy type to ensure they meet the required specifications for your project. Always procure from suppliers who offer warranties and after-sales support.</p>

- Q: Aluminum profile 606360056061, T5 and T6 hardness GB, how much?

- Generally divided into Vivtorinox hardness, Rockwell hardness and Vickers hardness and webster hardness. Our enterprises are generally in accordance with webster hardness test, GB 6063-T5 8HW 6063-T6 11.5HW6005-T5 15HW 6005-T6 15HW6061-T5 15HW 6061-T6 15HWIf you need other hardness units, you can refer to the conversion

- Q: Are aluminum profiles suitable for roofing systems that need to withstand strong wind loads?

- <p>Yes, aluminum profiles can be used for roofing systems that require high levels of wind load resistance. Aluminum is a lightweight yet strong material with excellent resistance to corrosion and weathering. It can be engineered into profiles that provide the necessary structural integrity to withstand high wind loads. The flexibility of aluminum allows for the creation of various shapes and designs that can be tailored to meet specific wind resistance requirements. Additionally, aluminum's durability and low maintenance make it a popular choice for roofing systems in areas prone to high winds.</p>

- Q: What are the different surface engraving or etching techniques for aluminum profiles?

- Aluminum profiles can be engraved or etched using various techniques, each with its own advantages and outcomes. Some commonly employed methods are as follows: 1. Chemical Etching: By selectively removing the top layer of the aluminum profile using chemicals, this technique enables precise and intricate designs to be etched onto the surface, making it ideal for decorative purposes. 2. Laser Engraving: Employing a high-powered laser beam to vaporize the aluminum surface, this approach yields a permanent etching. It allows for exceptional precision, making it suitable for detailed designs and logos. 3. Mechanical Engraving: This technique involves physically engraving the aluminum profile's surface using rotary cutters or diamond-tipped tools. It is frequently used in industrial applications, such as marking product codes or serial numbers. 4. Electrochemical Etching: By utilizing an electric current and an electrolyte solution, this method etches the aluminum surface. It is often used to create durable and legible markings, such as product labels or identification codes. 5. Sandblasting: This process entails directing abrasive particles at high speed onto the aluminum surface, removing its top layer. The result is a textured or frosted appearance, often employed for decorative purposes or to achieve a matte finish. 6. Acid Etching: Acid etching involves the use of an acid solution to selectively remove the top layer of the aluminum surface. It is commonly employed to create a matte or satin finish, as well as patterns or textures on the profile. These techniques present a wide array of options for aluminum profiles, allowing for customization, branding, or functional purposes. The selection of a specific technique depends on factors such as the desired design, level of detail, durability requirements, and intended application of the aluminum profile.

- Q: This question asks for guidance on selecting the appropriate size and shape of aluminum profiles for a specific application.

- <p>Choosing the right size and shape of an aluminum profile involves several steps. First, consider the load-bearing requirements and structural integrity needed for your application. Consult with engineering standards or use software that can simulate the stress and load on the profile. Second, consider the aesthetic and functional requirements, such as the profile's visibility and the need for specific features like slots or holes. Third, review the available profiles from suppliers, matching your needs with their offerings. Finally, prototype with the selected profile to ensure it meets all requirements before full-scale production. Always consult with aluminum profile manufacturers or suppliers for their expertise and recommendations.</p>

- Q: Can aluminum profiles be used for conveyor belts?

- Yes, aluminum profiles can be used for conveyor belts. Aluminum is a versatile and lightweight material that is commonly used in various industrial applications, including conveyor systems. Aluminum profiles offer several advantages for conveyor belts, such as high strength-to-weight ratio, corrosion resistance, and easy customization. These profiles can be easily fabricated into different shapes and sizes to match the specific requirements of the conveyor system. Additionally, aluminum profiles can be an economical choice as they require less maintenance and have a longer lifespan compared to other materials. Overall, aluminum profiles are a suitable option for conveyor belts due to their durability, versatility, and cost-effectiveness.

- Q: Can aluminum profiles be used in sports equipment manufacturing?

- Yes, aluminum profiles can be used in sports equipment manufacturing. Aluminum is a lightweight and durable material that is commonly used in the production of sports equipment such as bicycles, tennis rackets, golf clubs, and hockey sticks. It offers excellent strength-to-weight ratio, corrosion resistance, and flexibility for design customization, making it a popular choice for many sports-related applications.

- Q: What are the different types of protective coatings for aluminum profiles?

- There are several different types of protective coatings available for aluminum profiles. These coatings are designed to enhance the durability and longevity of the aluminum, while also providing aesthetic appeal. Some of the common types of protective coatings for aluminum profiles include: 1. Anodizing: Anodizing is one of the most popular and widely used protective coatings for aluminum. It involves an electrochemical process that creates a thin, transparent layer of aluminum oxide on the surface of the metal. This layer provides excellent corrosion resistance and can be further enhanced with various dye colors. 2. Powder Coating: Powder coating is a dry finishing process that involves applying a free-flowing, electrostatically charged powder onto the aluminum surface. The powder is then cured under heat, creating a durable and protective coating. Powder coating offers excellent resistance to impact, chemicals, and corrosion, and it provides a uniform and attractive finish. 3. Paint Coating: Paint coatings are commonly used for aluminum profiles, especially in applications where aesthetics is important. These coatings can be applied using various methods such as spraying, brushing, or dipping. Paint coatings provide protection against corrosion, UV rays, and other environmental factors, while also offering a wide range of color options. 4. E-Coating: E-coating, also known as electrocoating or electrophoretic deposition, is an immersion-based coating process. It involves submerging the aluminum profiles in a tank filled with a water-based paint solution and applying an electric current. This causes the paint particles to migrate and deposit onto the aluminum surface, resulting in a uniform and protective coating. E-coating provides excellent corrosion resistance and is often used as a primer before applying other coatings. 5. Clear Coating: Clear coatings are transparent protective layers that are often used to preserve the natural appearance of aluminum profiles while providing protection against corrosion and other environmental factors. These coatings can be applied as clear lacquers or clear anodizing, depending on the desired level of protection. It is important to consider the specific requirements of your aluminum profiles and the intended application when choosing a protective coating. Factors such as durability, corrosion resistance, aesthetics, and cost should be taken into account to ensure the best choice for your specific needs.

Send your message to us

Aluminum Heat Sink Extrusion Profiles for Window and Door with Advantage Price and Free Moulds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords