Aluminium Profile for Mechanical Engineering

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Profile for Mechanical Engineering Description

Aluminium Profile for Mechanical Engineering is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profile for Mechanical Engineering

Aluminium Profile for Mechanical Engineering | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profile for Mechanical Engineering

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profile for Mechanical Engineering

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profile for Mechanical Engineering

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

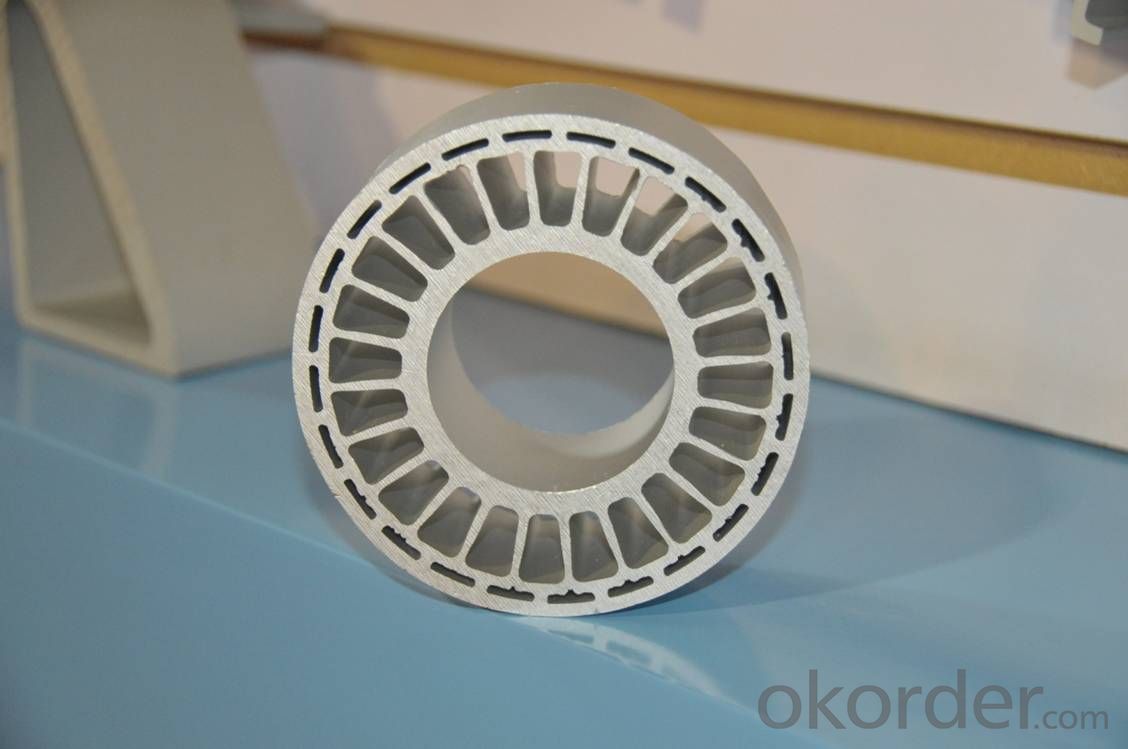

6. Image of Aluminium Profile for Mechanical Engineering

7. Package and shipping of Aluminium Profile for Mechanical Engineering

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can you quote me one according to the current market situation?

- Aluminum: aluminum ingot + processing fee + Spray + heat insulationAluminum plate: square meter, unit price (depending on thickness) + spraying, etc.You cannot quote without specific parameters

- Q: What are the aluminum profile markets in Cangzhou, Renqiu?

- Aluminum market, located in Renqiu city in Yi Zhen Zhang Liu Zhuang industrial area, if you find a direct about Liu Zhuang industrial zone can be. Known as the North's largest aluminum production base, I look not so good

- Q: Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Economic point of view, choose plastic film packaging materials. Yes, the price of the material must be more expensive, at one price per share.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of roofs.

- <p>Aluminum profiles in roofing offer several advantages, including their lightweight nature which reduces structural load, high corrosion resistance making them suitable for various climates, and ease of installation which can lower labor costs. They also have a long lifespan and can be recycled, contributing to sustainability. However, there are disadvantages such as higher initial costs compared to traditional materials, potential for dents or damage from impacts, and the need for regular maintenance to preserve their finish and prevent fading. Additionally, aluminum can be noisy during rain or hail, and it may not be as thermally efficient as some other roofing materials, potentially requiring additional insulation.</p>

- Q: Aluminum profile spraying process

- Powder coating construction technology and requirements of the powder electrostatic spraying is the use of the principle of high voltage electrostatic corona electric field. With high-voltage anode in the gun head on the metal guide, is formed by spraying electrode of the workpiece, the formation of a strong electrostatic field between the gun and the workpiece. When the compressed air as carrier gas, powder coating from guide rod for powder barrels by powder pipe to spray gun, the corona discharge guide rod is connected with the high voltage anode is generated, and the negative charge density in the vicinity of the powder, with a negative charge, and entered into the field of electrostatic field strength is very high, in the dual role of static electricity and gas. The powder evenly ground to powder layer formed on the surface of workpiece thickness uniformity, and heat curing into durable coating coating construction process:

- Q: Are aluminum profiles suitable for use as exterior walls in residential buildings?

- <p>Yes, aluminum profiles can be used for exterior walls in residential buildings. They offer several advantages such as durability, low maintenance, and resistance to corrosion. Aluminum profiles are lightweight, which makes them easier to install compared to heavier materials. They also have good thermal conductivity, which can be managed with proper insulation to maintain energy efficiency. Additionally, aluminum can be powder-coated in various colors, offering design flexibility. However, it's important to ensure that the aluminum profiles meet building codes and standards for structural integrity and weather resistance.</p>

- Q: This question asks for methods to protect aluminum profiles from damage during the processes of transportation and storage.

- <p>To prevent damage to aluminum profiles during transportation and storage, follow these practices: Use protective packaging such as bubble wrap or foam padding to cushion the profiles. Ensure that profiles are stacked evenly and securely to avoid pressure points. Store profiles in a dry, cool place away from direct sunlight and moisture to prevent warping or corrosion. Secure the cargo during transportation to prevent shifting, and handle with care to avoid dropping or mishandling. Regularly inspect storage areas for potential hazards like pests or leaks that could cause damage.</p>

- Q: Can aluminum profiles be used for exhibition stands or booths?

- Yes, aluminum profiles can be used for exhibition stands or booths. Aluminum is a popular choice for building exhibition stands and booths due to its lightweight yet durable nature. It provides structural stability while being easy to transport and assemble. Aluminum profiles can be easily customized and incorporated into various designs and configurations, making them versatile for different exhibition requirements. Additionally, aluminum is a highly recyclable material, aligning with sustainable practices often sought after in exhibition and event industries. Overall, aluminum profiles offer a cost-effective and practical solution for creating exhibition stands or booths.

- Q: What are the different packaging and shipping considerations for aluminum profiles?

- When dealing with the packaging and shipping of aluminum profiles, there are various factors to take into account. To begin with, it is important to use packaging materials that are sturdy and strong enough to protect the profiles from any external damage during transit. This may involve the use of materials such as corrugated cardboard boxes or wooden crates. Another significant consideration is the need for proper padding and cushioning inside the packaging to prevent any movement or shifting of the profiles. This can be achieved by utilizing protective packaging materials like foam inserts, bubble wrap, or packing peanuts. These materials serve to absorb shock and provide a layer of protection against impacts or vibrations that may occur during transportation. Furthermore, it is crucial to ensure that the packaging is securely sealed and fastened to avoid any accidental opening or harm to the profiles. This can be accomplished by using strong adhesive tapes or strapping materials to maintain the integrity of the packaging. The size and weight of the aluminum profiles should also be taken into consideration when selecting the appropriate packaging. Larger or heavier profiles may necessitate the use of custom-made crates or pallets to facilitate safe and efficient transportation. It is imperative to ensure that the packaging is specifically designed to handle the weight and dimensions of the profiles in order to prevent any structural damage. Moreover, it is essential to properly label and mark the packages to ensure their correct handling and identification during shipping. This includes clearly indicating fragile or delicate items, providing handling instructions, and marking the packages with necessary shipping information such as the destination address, contact details, and any specific instructions for the carrier. Lastly, it is vital to choose a reliable and experienced shipping carrier or logistics provider who specializes in handling aluminum profiles. They should possess the necessary expertise and equipment to safely and efficiently handle and transport these delicate products. In conclusion, considering the appropriate packaging materials, cushioning, sealing, labeling, and selecting a dependable shipping partner are crucial factors to consider when packaging and shipping aluminum profiles. This will ensure the secure delivery of the profiles to their intended destination.

- Q: How do you ensure proper electrical grounding with aluminum profiles?

- To ensure proper electrical grounding with aluminum profiles, it is important to follow a few steps. Firstly, it is crucial to clean the surface of the aluminum profiles thoroughly to remove any dirt, oil, or oxidation. This can be done using a suitable cleaning agent or abrasive pad. Next, make sure that the electrical connections are securely fastened to the aluminum profiles using appropriate connectors. Additionally, using conductive paste or gel can help improve the conductivity between the electrical connections and the aluminum profiles. Finally, regularly inspect the grounding system to check for any signs of damage or deterioration, and promptly address any issues that may arise.

Send your message to us

Aluminium Profile for Mechanical Engineering

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords