EXCELLENT EPS SANDWICH PANEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EXCELLENT EPS sandwich panel

1.Effective width:950,1,150mm

2.Thickness for eps :50/75/100mm

3.Thickness for steel sheet: 0.4-1.2mm(double faces),normal size is 0.326/0.376/0.426/0.476mm

4.Length: according to your request ,less than 6000mm suitable for the transport

5.EPS density: 14kg/m3

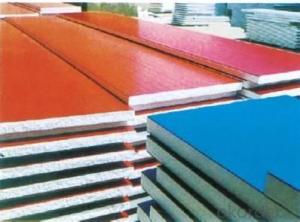

6.Character:

1). Light in weight, heat insulation, water resistant, noise-absorbing ,cheap in price

2) .Fire resistance raring: Grade A

sandwich panel sandwich panel price eps sandwich panel pu sandwich panel polyurethane sandwich panel sandwich panel house roof sandwich panel sandwich panel second hand sandwich panel

7.Usage:

1) Temporary offices, dormitories, warehouse and workshop in construction sites and in municipal works and residential resettlements

2) Temporary commercial housings in the cities, such as exhibition halls, shopping centers, offices and other housings for exhibition and sports

3) Holiday inns or container house, leisure villas and holiday homes in tourist spots.

4) Temporary houses used in large-scale fieldwork, such as exploiting energy sources and making tunnels, warehouse

5)Temporary houses in military field and temporary housings in earthquake, fire, hurricane and flood disaster-affected areas

6)large area suspended ceiling , separation of steel structure workshop, suspended ceiling, wall body

- Q: How are steel coils used in the production of pipes?

- Steel coils are used in the production of pipes by being uncoiled and then passed through a series of forming and welding processes. The coils are flattened and shaped into the desired pipe size and then welded together to create a continuous length of pipe.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Steel okorder /

- Q: my sister is making rolls and we have no idea what steel cut oats are. can someone please help with this?

- These are oat grains that are cut with steel sheers intstead of being put the a roller processing system . These are most favored for making true oat porridge . If you really hate preparing breakfast , purchase some of these . Place them in your crockpot over night with milk or water ( your choice ) add what you like raisins cranberries , nut other dried fruits turn on low . Breakfast will be ready and waiting when you get up in the morning just make the coffee or tea . My favorite is to mix in milk , shredded carrot , dried cranberries , b. walnuts and maple syrup . Note : contrary to my predecessor , these have more nutritiional value as they havenot been so heavily processed . Quick and instant oats are just a waste nutritionall speeking . Anything that must be fortified has been over processed .

- Q: which pokemon has the most steel pokemon???

- Transformers.

- Q: How do steel coils contribute to energy efficiency in appliances?

- Steel coils contribute to energy efficiency in appliances in several ways. Firstly, steel is a highly conductive material, allowing for efficient heat transfer. This means that appliances with steel coils, such as refrigerators or air conditioners, can cool or heat up faster, reducing energy consumption. Additionally, steel coils are durable and have excellent heat retention properties, meaning that once the desired temperature is reached, the coils can maintain it for longer periods without consuming additional energy. This helps appliances to operate more efficiently and save on electricity usage.

- Q: How are steel coils processed for edge trimming or slitting during processing?

- Steel coils are processed for edge trimming or slitting during processing by using specialized machinery. The coils are uncoiled and fed through a slitting machine, which cuts the coil into narrower strips. These strips are then passed through an edge trimming machine, which removes any irregularities or excess material from the edges. This process helps to ensure that the steel coils meet the desired specifications and are ready for further processing or use in various industries.

- Q: what is the chemical process that makes steel harder when it is heated and cooled rapidly?what does the heating of it do to the atoms?what does the cooling of it do to the atoms?what makes tempered steel so strong compared to untempered steel?

- You can't temper all steels. Generally the material must be a high-carbon or tool steel. Different alloys temper differently, and tempering is usually done to get a specific set of characteristics, so you must know what you are working with and use the right methods and temperature. If you do it wrong, the material may be hard but too brittle for the purpose or have other issues. It can be simple, such as heating to a dull red, carbonizing the surface (use an acetylene rich flame until it blackens the surface) and oil quenching. Do that to a piece of tool steel (like a screwdriver) and it will case (surface) harden it to the point you can't scratch it with a file. Tempering changes the way the molecular structure in the metal is linked and oriented.

- Q: i need a company that sells strong steel doors because my neighbors apartment was broken into. I need a strong steel door for the outside of the home, where you first enter. please list places in the US, or in NY.

- The okorder /

- Q: Are Steel buildings Fire Resistant, just want to know as I am going to owe it . Suggestions required…………..

- A true structural steel building is composed of steel columns, steel bar joist,steel purlins,steel roof frames,and steel siding. This is all load bearing structural steel. The vulnerable area of a steel building is the exposure of this steel to extreme temps during a fire. Steel becomes weak at high temps and begins to twist and distort like a noodle in hot water. Most all steel buildings now are specified by the architect/engineer to have fire retardant spray applied to the key components to protect against high heat during a fire. Even with that some beams/columns are also wrapped with several layers of type x fire rated drywall. Multi story steel buildings usually have lightweight concrete poured over steel decking for all floors above the ground floor. Any and all penetrations in these concrete floors must be sealed around to stop fire and smoke from spreading from one floor to the next, and fire rated doors at all stairways to each floor. Even ductwork that runs to other floors must have fire rated dampers that close if signaled by a sensor, this stops smoke/fire from spreading through the ductwork. Sprinkler systems are usually required in new structures that exceed at pre-determined square footage by the state you are in. Hope this helps you out.

Send your message to us

EXCELLENT EPS SANDWICH PANEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords