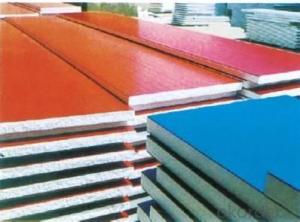

EXCELLENT SANDWICH PANEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EXCELLENT sandwich panel

1.Effective width:950,1,150mm

2.Thickness for eps :50/75/100mm

3.Thickness for steel sheet: 0.4-1.2mm(double faces),normal size is 0.326/0.376/0.426/0.476mm

4.Length: according to your request ,less than 6000mm suitable for the transport

5.EPS density: 14kg/m3

6.Character:

1). Light in weight, heat insulation, water resistant, noise-absorbing ,cheap in price

2) .Fire resistance raring: Grade A

sandwich panel sandwich panel price eps sandwich panel pu sandwich panel polyurethane sandwich panel sandwich panel house roof sandwich panel sandwich panel second hand sandwich panel

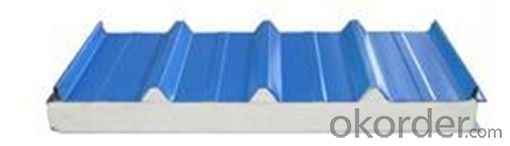

7.Usage:

1) Temporary offices, dormitories, warehouse and workshop in construction sites and in municipal works and residential resettlements

2) Temporary commercial housings in the cities, such as exhibition halls, shopping centers, offices and other housings for exhibition and sports

3) Holiday inns or container house, leisure villas and holiday homes in tourist spots.

4) Temporary houses used in large-scale fieldwork, such as exploiting energy sources and making tunnels, warehouse

5)Temporary houses in military field and temporary housings in earthquake, fire, hurricane and flood disaster-affected areas

6)large area suspended ceiling , separation of steel structure workshop, suspended ceiling, wall body

- Q: Many gerber knives are made out of what gerber calls high Carbon steels and I was wondering if anyone knew exactly what is this mysterious steel.

- The carbon content of the knife is done during the smelting process.For instance a knife that has a high carbon content will keep an edge much longer than one with a lower content. It is tricky because too much will cause the knife to be brittle and break easily. Annealing is also part of the process of knife making.

- Q: How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors as a crucial component for constructing the compressor's internal structure, such as the casing and housing. The steel coils provide strength, durability, and stability to the compressor, allowing it to withstand high pressure and temperature conditions. Additionally, the coils are often used in the construction of the compressor's motor, providing support and ensuring efficient operation. Overall, steel coils play a vital role in the manufacturing of industrial compressors by providing the necessary structural integrity and functionality.

- Q: How are steel coils used in the manufacturing of agricultural structures?

- Steel coils are used in the manufacturing of agricultural structures as they provide the necessary strength and durability required for building structures such as barns, grain storage facilities, and equipment sheds. These coils are often used to fabricate beams, columns, and trusses, ensuring structural stability and resistance to harsh weather conditions. Additionally, steel coils are also used in the production of agricultural machinery and equipment, further enhancing the efficiency and reliability of farming operations.

- Q: What are the pros with stainless steel? You don't have to oil them as much or you don't have to oil them at all?Is the rifling in the barrel typically stainless steel as well? if so, is this better accuracy or does the rifling last longer then conventional?are they worth the extra money?Thanks for any info you can provide!

- Stainless Steel Handguns

- Q: How are steel coils used in the manufacturing of agricultural sprayers?

- Steel coils are used in the manufacturing of agricultural sprayers to create the frames and structures that provide stability and durability to the sprayer. The coils are shaped and welded to form the main body and support components, ensuring the sprayer can withstand the rigors of field use and maintain its functionality for extended periods.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. They are often recycled and repurposed for various applications in different industries.

- Q: How are steel coils processed for slitting or shearing?

- Steel coils are processed for slitting or shearing by first uncoiling the coil and then feeding it through a slitter or shear machine. The machine applies pressure or cuts the steel coil into narrower strips or smaller pieces, respectively. This allows for the production of various widths or sizes of steel products, which can be used in different industries.

- Q: What are the different steel coil specifications?

- The different steel coil specifications refer to the various parameters and characteristics that define a steel coil. These specifications include dimensions such as thickness, width, and length, as well as the type of steel used, coating or finish, and the industry standards it complies with. Other specifications may include tensile strength, yield strength, and chemical composition, which determine the coil's suitability for specific applications.

- Q: What is the standard weight of steel coils?

- The standard weight of steel coils can vary depending on the specific type and dimensions of the coil. However, a common range for steel coils is between 3 to 25 tons.

- Q: What are the different types of steel coil finishing processes?

- There are several different types of steel coil finishing processes that are used to enhance the appearance and properties of the steel coils. Some of the common types include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, which creates a protective layer on the surface of the coil. This not only enhances the corrosion resistance of the steel but also provides a smooth and visually appealing finish. 2. Cold rolling: Cold rolling is a process in which the steel coil is passed through a series of rollers at room temperature to reduce its thickness and improve its surface finish. This process can impart a variety of finishes, ranging from a matte to a highly polished surface. 3. Electro-galvanizing: In this process, a thin layer of zinc is applied to the surface of the steel coil through an electrolytic deposition. Electro-galvanizing is commonly used for applications that require a thinner zinc coating and a more uniform finish. 4. Pickling and oiling: Pickling involves treating the steel coil with an acid solution to remove any scale or surface impurities, resulting in a clean and smooth surface. After pickling, the coil is usually coated with oil to prevent rusting during storage and transportation. 5. Powder coating: Powder coating is a popular finishing process that involves applying a dry powder to the steel coil and then curing it under heat to form a durable and attractive finish. This method allows for a wide range of colors and finishes to be applied to the steel. 6. Paint coating: Similar to powder coating, paint coating involves applying a liquid paint to the surface of the steel coil. This process can provide a decorative finish while also offering protection against corrosion and other environmental factors. These are just a few examples of the different types of steel coil finishing processes. The choice of the finishing method depends on the specific requirements of the application, such as the desired appearance, corrosion resistance, and durability.

Send your message to us

EXCELLENT SANDWICH PANEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords