Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvalume/Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvalume/Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized /Galvalume Steel Coil Images

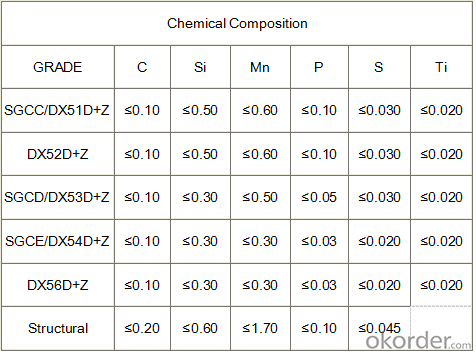

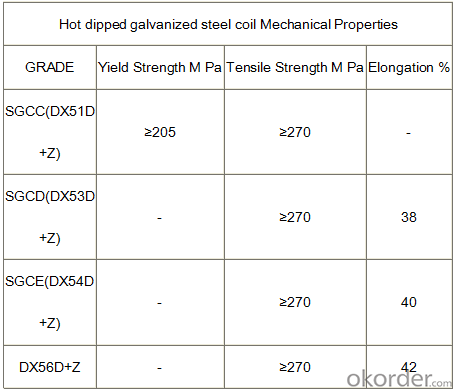

4.Galvanized /Galvalume Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized/Galvalume Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can steel coils be coated with chrome?

- Yes, steel coils can be coated with chrome. The process of chrome plating involves the application of a thin layer of chromium onto the surface of the steel coils to enhance their appearance, provide corrosion resistance, and improve their durability.

- Q: What is stainless steel 316, and what are its properties and uses?

- if you want to know details, try looking it up in wikipedia. It's not a reliable source for everything, but truly technical stuff is good. It lists the exact range of elements, heats, and other things, as well as uses and things it shouldn't be used for.

- Q: What are the different types of steel alloys used in coil production?

- There are several types of steel alloys used in coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These alloys offer varying levels of strength, corrosion resistance, and formability, making them suitable for different applications in industries such as automotive, construction, and manufacturing.

- Q: I was wondering what material most common motorcycle gas tanks are made out of? is it steel? stainless steel? aluminum? what are the advantages and disadvantages or each?

- Steel is most common. Aluminum is lighter but it's harder to form, so more expensive. Plus it dents more easily. And you can't use a magnetic tank bag. I've seen stainless steel tanks but they were usually specially made.

- Q: I have one and need info about it??....It has a wooden case around the steel necks.and 20 strings,Twin Tens.

- well, it was made sometime before 1981, because that's when Fender quit making 10 string steel guitars. Without any more information than what you've given me, it could be the Pedal 2000, the PS210, or the Artist Dual 10. Fender made steel guitars from the 1950s through 1981, so it could be from any time in there. I hope you have the pedals with it. The 10-string and dual 10-string models were quite expensive in their day. Unfortunately, if you're thinking of reselling it, you're probably not going to get a lot of money for it unless you find a pedal steel player, and like I said, having all the pedals is very important in that case. Anyway, hope this helped. Good luck. If I were you I'd learn to play it. Pedal steel players are always in demand.

- Q: What is the purpose of coating steel coils?

- The purpose of coating steel coils is to provide protection against corrosion, enhance durability, and improve the aesthetic appearance of the steel. Coatings create a barrier between the steel surface and the environment, preventing moisture, chemicals, and other corrosive elements from reaching the metal. Additionally, coatings can offer additional benefits such as heat resistance, UV protection, and improved paint adhesion, making the steel coils suitable for a wide range of applications in various industries.

- Q: How do steel coils contribute to the manufacturing of steel furniture?

- Steel coils play a crucial role in the manufacturing of steel furniture. These coils, which are made of high-quality steel, serve as the primary raw material for the production of various furniture items. Firstly, steel coils are used to create the framework and structure of steel furniture. These coils can be easily cut, shaped, and welded into various shapes and sizes, allowing manufacturers to create sturdy and durable furniture frames. The flexibility of steel coils enables the production of furniture with intricate designs and unique shapes, providing both functional and aesthetic value. Additionally, steel coils are also used in the production of springs for furniture such as sofas and chairs. The elasticity and strength of the steel coils make them ideal for creating comfortable and supportive seating options. These coils are carefully formed and integrated into the furniture, ensuring that the seating surface provides the necessary resilience and flexibility for a comfortable experience. Moreover, steel coils contribute to the overall durability and longevity of steel furniture. Steel is known for its high tensile strength and resistance to wear and tear, making it an excellent choice for furniture that is subjected to heavy use and weight load. The use of steel coils ensures that the furniture can withstand years of regular use without compromising its structural integrity. Furthermore, steel coils are often treated with various finishes and coatings to enhance their appearance and protect them from corrosion. These coatings can be applied to the coils before they are shaped into furniture components, ensuring that the final product maintains its aesthetic appeal and remains resistant to rust and other forms of damage. In conclusion, steel coils are an essential component in the manufacturing of steel furniture. They provide the necessary strength, flexibility, and durability required to create sturdy furniture frames, comfortable seating surfaces, and long-lasting products. Without steel coils, the production of steel furniture would not be possible, and the quality and performance of the final products would be compromised.

- Q: What kind of insulation should be used in a steel building?

- Fiberglass batts or spray on foam both work well

- Q: I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI boots, but would very much love to be able to rock a pair of cruelty free boots/shoes on the job!It does not have to be certified vegan just all man-made materials and no leather/sued and other such stuff where animals have to die. It would make me no better than the massive slaughterhouse industries and such. Valueing money of ver live/morals. I don't want one of the first things I need to do in my manufacturing job is compromising my morals. :3So if you know of an ANSI vegan friendly boot brand PLEASE TELL ME! *gets on knees begging*Money isn't really an option for me, I'll just continue borrowing my dad's boots till I save up enough!Thanks in advance! :D

- Vegan okorder /... I don't know if they're ANSI shoes, so you might want to ask.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords