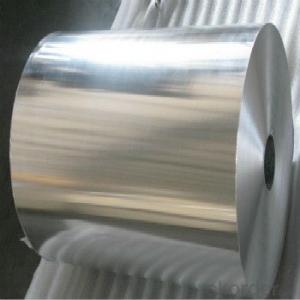

P1020 Aluminum

P1020 Aluminum Related Searches

Aluminum 10 22 Stock 1050 Aluminum Plate 1050 Aluminum Coil 10 Gauge Aluminum Plate 10mm Aluminum Plate 030 Aluminum Coil 2024 Aluminum Sc10 Aluminum Top Plate 10mm Thick Aluminum Plate Cold Forming Aluminum Aisi 1020 Aluminum Plate 10mm 20mm Aluminum Plate Pvc Aluminum Coil K100 Aluminum Plate Circle Aluminum Angle Aluminum Aluminum Corrosion Protection Aisi 1020 Plate Coil Aluminum Large Diameter Aluminum Tube K100s Aluminum Plate Aluminum Periodic Table 5052 0 Aluminum Plate Aisi 1020 Hot Rolled 1100 Aluminum Coil Aluminum Girder Aluminum Angle Aluminum T Plate Aluminum Coil 1100P1020 Aluminum Supplier & Manufacturer from China

P1020 Aluminum is a type of aluminum alloy that is widely recognized for its excellent properties, such as high strength, corrosion resistance, and good weldability. This alloy is made from a combination of aluminum and other elements, including copper, magnesium, and manganese, which contribute to its unique characteristics. The P1020 Aluminum is commonly used in various industries, including aerospace, automotive, and construction, where its lightweight and durable nature is highly valued. It is particularly favored for applications that require high strength-to-weight ratios and resistance to harsh environmental conditions.In terms of usage, P1020 Aluminum is often employed in the manufacturing of components that need to withstand significant stress, such as aircraft parts, automotive structures, and architectural elements. Its ability to maintain its integrity under extreme temperatures and pressures makes it an ideal material for these demanding applications. Furthermore, P1020 Aluminum's resistance to corrosion means that it can be used in environments where other materials might succumb to rust or degradation, such as marine applications or outdoor structures.

Okorder.com is a leading wholesale supplier of P1020 Aluminum, offering a vast inventory of this high-quality material to customers around the world. With a commitment to providing top-notch products and exceptional service, Okorder.com ensures that customers have access to the P1020 Aluminum they need for their projects, whether they are large-scale industrial operations or smaller-scale fabrications. By maintaining a large inventory and offering competitive prices, Okorder.com has become a trusted source for P1020 Aluminum, helping customers to achieve their goals and bring their projects to fruition.

Hot Products