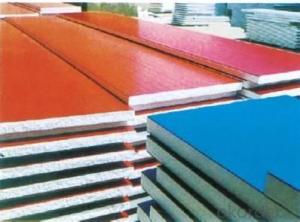

Styrofoam Excellent Steel Rock Wool Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Bare packing |

| Delivery Detail: | 7 days upon downpayment or LC |

Specifications

1.Rock wool sandwich panel

2.Width:950mm-1150mm

3.Thickness:50mm-175mm

4.Length: container length

5.Color: All Ral

Rock Wool Sandwich Panel :

1 Brief induction:

The rock wool sandwich panel is composed by three layers, up and lower steel sheet with specific core materials. The panels are formed by laminating and pressing with 2 components PU glue through forming machines;

2 Specification:

1. Width:950mm-1150mm

2.Thickness:50mm-175mm

3.Length: as per customer require

4.Color: All Ral color.

5.Surface: Covered by protection PE film

Up/Lower steel sheet:

Thickness: 0.4mm-0.8mm

Width: 960mm

Material: color-coated panel/zinc plate,Alu-Zinc steel sheet

Surface: LDPE Guard Film

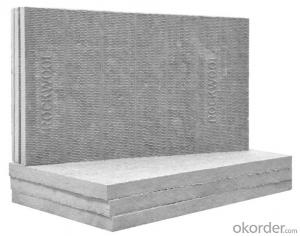

Core material:

Tpye: Rock Wool

Density: 80-120kg/ m3

3 Connection types:

1. Wall Panel: Self-insert Connection;

2. Roof Panel: Overlap Connection;

Screw and Accessories is available as your design.

4 Advantages

Light Weight,Sound Insulation

Heat Insulation,Preservation

Environmental protecion

Waterproof and damp resistant

Fire,Water Proof

Fast, Easy

Good appearence

PS: The sandwich panel has been a new type of multi-purpose construction material. It is featured with temperature keeping, hot & sound insulation, water-proof and fire-resistant functions as well as light weight and decorative application. It is widely used as the wall or roof for industrial or residential buildings, such as cold storages, industrial workshops, prefabricated houses, etc.

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- Color steel sandwich panels have the effect of thermal insulation, these two types of panels can be used for houses and workshops, are able to waterproof

- Q: Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q: Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- The greater the density. Strength is higher. But the thermal conductivity is the lower However, I do squeeze nail fan teeth both hands and pay only try to dig a thin plate of this line a little bit of time it is recommended that you still choose the high density of the thermal conductivity will be low, not much lower. Just some of the sales of the plate to the low density that means a good thing only.

- Q: Can sandwich panels be used for noise barriers?

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q: Color steel sandwich panels and synthetic resin tile which is more market

- Must be embedded in the concrete beam on the concrete beam, and then fasten the steel pipe connection, the use of steel connection, the connection point can be 2 steps 3 cross, the specific calculation by the book construction

- Q: Are sandwich panels suitable for retail outlets?

- Sandwich panels, consisting of two rigid layers and a core material, are ideal for retail outlets. With their strength and durability, the rigid layers ensure longevity, while the core material provides insulation and soundproofing. In a retail setting, sandwich panels serve various purposes. They can serve as sleek and modern exterior cladding, enhancing the building's appearance. Additionally, they can be utilized for interior walls and partitions, creating distinct areas within the store. The installation of sandwich panels is effortless, and they can be tailored to meet the specific requirements of the retail outlet. They can be painted or adorned to align with the store's branding and aesthetics. Moreover, their lightweight nature enables easy transportation and assembly, making them a cost-effective choice. The benefits of sandwich panels extend beyond aesthetics. They offer exceptional thermal insulation, ensuring a comfortable shopping experience regardless of the season. This leads to energy savings and a pleasant environment for customers. Ultimately, sandwich panels are a suitable option for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an appealing and functional solution for both the store's exterior and interior.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs The substrate of the color steel plate is a cold-rolled substrate, a hot-dip galvanizing substrate, and an electro-galvanized substrate Coating types can be divided into polyester, silicon modified polyester, polyvinylidene fluoride and plastic sol The surface condition of the color steel plate can be divided into coated board, embossed plate and printing plate The color steel plate is widely used in the construction of household appliances and transportation industry The construction industry is mainly used for steel industry, airport, warehouse and freezing industry Commercial buildings of the roof walls and doors, etc, civil buildings using less color plate

Send your message to us

Styrofoam Excellent Steel Rock Wool Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords