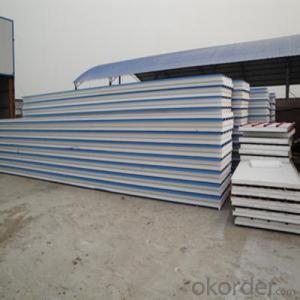

EPS roof sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPS sandwich panel production process adopts the colored steel plate as surface board, and the core material is the self-extinguishing closed cell polystyrene foam, It is a kind of high-strength composited building materials, and it was formed in the automated continuous molding machine, by combining the pressed colored steel with the High Strength Adhesives. It has the characteristics of complete insulation and fire-proof, fast construction speed, durability, and beautiful appearance, etc.

The above sandwich panels have been widely used in warehouses, factories, exhibition hall, prefabricated house, container houses and other industrial and civil buildings

One: Technical Specifications

1.Density: 8-24 kg/m3

2.Coefficient of thermal conductivity:k=0.025W/m.k

3.Compressive strength: 2.0 kg/cm2

4.Dimensional stability under low tempeaturelinear change rate,-25.24hr: 1.0,%

5.Water absorptionV/V,24hr:,30%

6.Fire retardance (Oxygen index) 26 B2 Grade

Two: Specification:

Steel sheet: up/bottom 0.3-0.6mm,colored steel plate, pained and galvanized

Insulated material: polyurethane (PU), Density: 10-30 kg/m3

Style: H- style board, match board

Width: match board, 950mm,960mm,1150mm (Effective width)H- style board, 1000mm,1200mm (Effective width)

Thickness: match board, 30-200mm; H-style board, 25-100mm

Length: According to the requirements and transportation terms

Color: According to the requirements (Regular color is White Gray, Navy)

- Q: What are the design considerations for steel storage tanks?

- Some design considerations for steel storage tanks include the choice of material, thickness and strength of the steel, corrosion protection measures, structural stability, seismic design, and appropriate venting and drainage systems. Additionally, factors such as the intended contents, capacity, location, and environmental regulations must be taken into account during the design process.

- Q: How are steel structures used in historical renovations and restorations?

- Historical renovations and restorations frequently utilize steel structures to provide support and reinforcement to existing buildings. These structures are typically concealed within the walls, floors, or ceilings, preserving the building's historical aesthetics while guaranteeing stability and safety. The strength and durability of steel structures make them particularly advantageous in historical renovations. Steel is renowned for its ability to bear heavy loads, making it an ideal material for supporting aging or weakened structures. Incorporating steel beams or columns allows architects and engineers to distribute the weight of the building more effectively, preventing further deterioration and potential collapse. Another benefit of steel structures in historical renovations lies in their flexibility and versatility. Steel can be fabricated into various shapes and sizes, enabling it to adapt to the unique architectural features of historical buildings. This means that even intricate and delicate designs can be supported without compromising the building's historical integrity. Additionally, steel structures help address common issues found in older buildings, such as sagging floors, cracked walls, or leaning structures. By strategically placing steel elements, these problems can be rectified, ensuring the building's longevity and preventing further damage. Steel structures also offer advantages in terms of fire resistance and sustainability. Steel is a non-combustible material, safeguarding historical buildings from fire hazards. Furthermore, steel is highly recyclable, making it an environmentally friendly choice for renovations and restorations. Overall, steel structures play a vital role in historical renovations and restorations, providing the necessary support, strength, and flexibility to preserve and enhance these architectural treasures. They allow for the preservation of historical aesthetics while ensuring the safety, stability, and longevity of the buildings for future generations to appreciate and enjoy.

- Q: What are the different types of steel curtain wall systems?

- There are several different types of steel curtain wall systems, including stick-built systems, unitized systems, and spider systems. Stick-built systems involve assembling the steel frame on-site, while unitized systems come pre-assembled and are installed as complete units. Spider systems use a series of cables and fittings to support the glass panels, creating a unique and visually striking appearance. Each type of system has its own advantages and is chosen based on the specific requirements of the project.

- Q: How are steel structures used in cultural and performing arts centers?

- Cultural and performing arts centers extensively utilize steel structures for various reasons. Primarily, steel offers the necessary strength and durability to support intricate architectural designs, resulting in visually stunning and one-of-a-kind buildings. This is especially vital in cultural and performing arts centers, where the structures must accommodate large open spaces, high ceilings, and expansive auditoriums. Furthermore, steel is a versatile material that allows for flexibility in design and construction. Architects and engineers can easily shape and fabricate steel into different forms, enabling the creation of intricate and innovative structures that enhance the aesthetic appeal of cultural and performing arts centers. Additionally, steel's ability to span long distances without excessive columns or supports ensures an unobstructed view for the audience, creating an immersive experience during performances. Moreover, steel structures provide excellent fire resistance, a crucial feature in buildings that accommodate large crowds. Steel beams and columns are inherently fire-resistant and can withstand high temperatures. This ensures the safety of occupants and protects valuable artworks and artifacts housed within cultural and performing arts centers. In addition to their structural advantages, steel structures facilitate efficient construction processes. Prefabricating steel components off-site reduces construction time and minimizes disruptions within the center. The lightweight nature of steel also reduces the overall load on the foundation, resulting in cost savings in terms of materials and construction time. Lastly, steel structures offer easy modification and expansion, enabling cultural and performing arts centers to adapt to changing needs and requirements. This flexibility is particularly important in venues that host a wide range of events, such as concerts, exhibitions, and theatrical performances. Overall, steel structures play a critical role in cultural and performing arts centers by providing strength, durability, design flexibility, fire resistance, efficiency in construction, and adaptability. They contribute to the creation of iconic and functional buildings that enhance the artistic experience for both performers and audiences.

- Q: How are steel structures used in theme parks and entertainment venues?

- Steel structures are commonly used in theme parks and entertainment venues due to their durability, strength, and design flexibility. They are utilized in the construction of roller coasters, water slides, observation towers, and other thrilling rides. Steel provides the necessary support and stability to ensure the safety of these structures, allowing for the creation of large-scale and intricate attractions that can withstand the forces experienced in amusement parks. Additionally, steel structures are often used for the construction of entertainment venues such as stadiums and concert halls, providing ample space and structural integrity for hosting large crowds and supporting impressive stage designs.

- Q: How do steel structures contribute to the overall accessibility and inclusivity of a building?

- Steel structures can play a crucial role in enhancing the overall accessibility and inclusivity of a building in several ways. Firstly, steel is a lightweight and versatile material that allows for the construction of structures with large open spaces and minimal support columns. This open layout can greatly improve accessibility within a building, making it easier for people with mobility aids such as wheelchairs or walkers to navigate through the space. Additionally, steel structures can be easily modified or expanded to accommodate changing accessibility needs. For example, ramps or elevators can be seamlessly integrated into the building's design, ensuring that individuals with physical disabilities can access all areas of the building. Steel's flexibility also allows for the installation of features like widened doorways or accessible bathrooms, further promoting inclusivity for individuals with disabilities. Moreover, steel structures are known for their durability and strength, allowing for the construction of buildings that meet or exceed accessibility standards. This ensures that the building is safe and robust, providing a secure environment for all occupants, including those with disabilities. Furthermore, steel structures are often designed with sustainability in mind, incorporating energy-efficient features such as natural lighting and ventilation systems. These eco-friendly designs not only reduce the building's environmental impact but also contribute to a healthier and more comfortable indoor environment for everyone, including individuals with sensitivities or allergies. Lastly, steel structures can be constructed efficiently, reducing construction time and costs compared to other building materials. This affordability can potentially lead to more accessible and inclusive buildings being constructed, as it allows developers and organizations to allocate resources towards accessibility features and services, such as accessible parking, signage, or assistive technologies. In conclusion, steel structures contribute significantly to the overall accessibility and inclusivity of a building by providing a flexible and durable framework that can be easily modified to meet the needs of individuals with disabilities. From open layouts and easy navigation to the incorporation of accessibility features, steel structures play a vital role in creating buildings that are welcoming and accessible to all.

- Q: What is the role of steel in building information modeling (BIM)?

- The role of steel in building information modeling (BIM) is to provide accurate and detailed representation of steel components within the virtual model of a building. This includes creating 3D models of steel structures, generating fabrication drawings, and coordinating steel elements with other building systems. BIM helps improve the efficiency and accuracy of steel construction by enabling better collaboration, clash detection, and analysis of steel components, resulting in faster construction timelines and reduced costs.

- Q: What are the different methods of steel structure fire protection?

- There are several methods of steel structure fire protection that are commonly used to ensure the safety and integrity of steel structures in the event of a fire. These methods include: 1. Intumescent coatings: Intumescent coatings are a popular method of fire protection for steel structures. These coatings are typically applied to the surface of the steel and provide a protective layer that expands when exposed to high temperatures. This expansion creates a barrier that insulates the steel and slows down the heat transfer, giving more time for evacuation and fire-fighting efforts. 2. Fire-resistant insulation: Fire-resistant insulation materials, such as mineral wool or fiberglass, are commonly used to protect steel structures. These materials are installed around the steel members to provide insulation and prevent the rapid spread of fire. They help to maintain the structural integrity of the steel by reducing the heat transfer and protecting it from the direct flame. 3. Fireproofing sprays: Fireproofing sprays are another method of steel structure fire protection. These sprays are typically made of cementitious materials or fiber-reinforced polymers and are sprayed onto the surface of the steel. They form a durable protective layer that acts as a barrier against the flames and heat, minimizing the damage to the steel structure. 4. Fire-resistant boards: Fire-resistant boards, such as gypsum or calcium silicate boards, are often used for fire protection of steel structures. These boards are installed around the steel members to provide a protective barrier against fire. They are effective in preventing the heat transfer and can withstand high temperatures, thus safeguarding the steel structure. 5. Structural fire-resistant coatings: Structural fire-resistant coatings are specifically designed to protect steel structures from fire. These coatings are often made of epoxy-based or cementitious materials and are applied directly to the steel surface. They provide a heat-resistant layer that slows down the rate of temperature rise on the steel, preventing structural failure. It is important to note that the selection of the appropriate method for steel structure fire protection depends on factors such as fire rating requirements, building codes, and the specific environment in which the structure is located. Professional fire protection engineers and consultants should be involved to ensure that the chosen method is in compliance with the applicable regulations and provides the necessary level of fire resistance for the steel structure.

- Q: How are steel structures used in the construction of manufacturing plants?

- Due to their numerous advantages and benefits, steel structures are extensively utilized in the construction of manufacturing plants. The primary reason for their popularity is the high strength and durability of steel structures, which make them perfect for supporting large industrial equipment and machinery. These structures can withstand heavy loads and extreme weather conditions, ensuring the safety and longevity of the manufacturing plant. In addition, steel structures offer a great deal of flexibility in design and construction. They can be easily customized to meet the specific requirements of a manufacturing plant, enabling efficient use of space and optimal layout of production lines. Moreover, the lightweight nature of steel allows for faster construction times, resulting in reduced project costs and timelines. Steel structures also possess high resistance to fire, termites, and other pests, making them a secure choice for manufacturing plants with a high risk of accidents or damage. Furthermore, steel is a sustainable and recyclable material, making it an environmentally friendly option for construction. Furthermore, steel structures provide a clear span, meaning there are no columns or supports obstructing the floor area. This feature allows for greater flexibility in arranging machinery and equipment, maximizing productivity and efficiency in the manufacturing process. Overall, steel structures offer a cost-effective, durable, and versatile solution for constructing manufacturing plants. Their strength, flexibility, and resistance to various hazards make them the ideal choice for creating a safe and efficient production environment.

- Q: How are steel structures used in the construction of agricultural buildings?

- Steel structures are commonly used in the construction of agricultural buildings due to their durability, strength, and cost-effectiveness. They provide the necessary support and stability required for housing livestock, storing equipment and crops, and protecting agricultural produce. Steel frames can withstand harsh weather conditions, provide ample space for large-scale farming activities, and are easily customizable to meet specific needs. Additionally, steel structures are resistant to fire, pests, and rot, making them a reliable choice for long-lasting agricultural buildings.

Send your message to us

EPS roof sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords