EPDM Waterproof Membrane Made from DUPONT Rubber

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane Made from DUPONT High Quality Rubber

Instruction of EPDM Membrae:

EPDM Rubber membrane for Waterproofing is the modified materials which is widely used at home and abroad in the kinds of roofs, tunnel, basement such sorts of constructions' waterproofing. They are based upon EPDM rubber with modifier, softener and accelerant assistants added to provide flexibility and stability .

Through the precise ingredients, mixing, extrusion, rolling, curing processes to made of modified EPDM Waterproofing material with high strength and high flexibility.

Advantages of EPDM Membrane:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications of EPDM Membrane:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications of EPDM Membrane:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

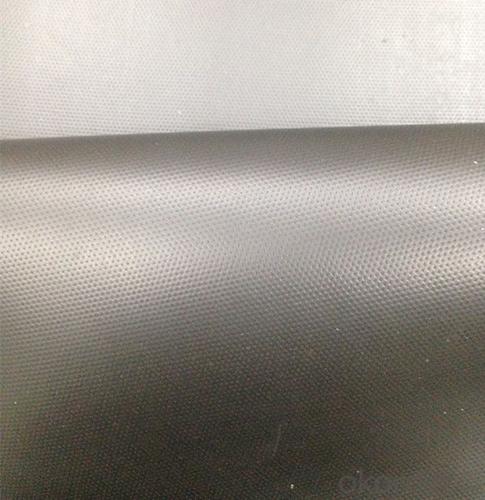

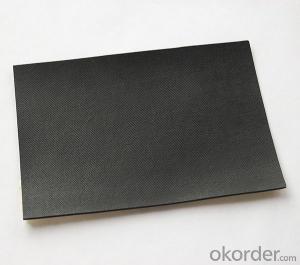

Photos of EPDM Membrane:

- Q: Can a waterproofing membrane be installed over existing coatings or sealants?

- Installing a waterproofing membrane over existing coatings or sealants is possible, but it depends on the condition of the surface. Before proceeding, it is crucial to ensure that the surface is clean, dry, and devoid of any loose or damaged material. Adequate surface preparation plays a vital role in ensuring proper adhesion of the new membrane and effective waterproofing. To avoid any potential problems or system failure, it is advisable to seek advice from a professional regarding the compatibility of the existing coatings or sealants with the waterproofing membrane.

- Q: Waterproof building materials after the construction of drums, bubble is what reason?

- Reason 2: Construction, due to the construction of the membrane waterproof layer of paving is not true, so that part of the empty, remain in which to form a bubble. Control measures: in the asphalt waterproofing membrane construction, the first surface of the coil clean. When laying the web, the mastic should be painted evenly and carefully compaction work to enhance the cohesive force between the web and the base, the web and the web. High polymer modified asphalt waterproofing membrane construction, the flame heating to be uniform, full, moderate. Paving to roll forward while hot, while rolling with a pressure roller to exclude the air below the coil.

- Q: Are waterproofing membranes resistant to earthquake movements?

- Waterproofing membranes are designed to prevent the intrusion of water and moisture into structures, such as buildings and basements. While they are highly effective in protecting against water damage, they are not specifically designed to resist or withstand earthquake movements. Earthquakes involve the shaking and movement of the ground, which can exert significant forces on structures. Waterproofing membranes are not typically engineered to absorb or distribute these forces in the same way as seismic-resistant materials or building techniques. However, it is worth noting that some waterproofing systems may have a certain degree of flexibility or elasticity, which could potentially provide some resistance to minor ground movements during an earthquake. These properties may help the membrane to maintain its integrity and prevent water intrusion in the event of slight shifting or settling. Ultimately, when it comes to earthquake resistance, it is crucial to employ specialized seismic design principles and techniques that are appropriate for the specific location and building requirements. Waterproofing membranes should be used in conjunction with these seismic-resistant measures to ensure the overall structural integrity and safety of a building during seismic events.

- Q: Can a waterproofing membrane be used in conjunction with soundproofing materials?

- Using waterproofing membranes in conjunction with soundproofing materials is a common practice in construction projects. Waterproofing membranes are typically employed to prevent water from entering a structure, while soundproofing materials are used to minimize noise transmission. Although these materials serve different purposes, they can be utilized simultaneously to achieve both waterproofing and soundproofing advantages. For instance, in buildings with basements or bathrooms, waterproofing membranes can be installed on the walls or floors to prevent water infiltration. Subsequently, soundproofing materials can be added on top of the membranes to reduce noise transmission from adjacent areas. By combining these two materials, a building can be safeguarded against water damage while also providing a quieter and more comfortable environment for its occupants.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Yes, a waterproofing membrane can be used in areas with high groundwater levels. Waterproofing membranes are designed to prevent the penetration of water and can be effective in areas where groundwater levels are high. However, it is important to ensure that the membrane is properly installed and meets the specific requirements of the site conditions to ensure optimal performance.

- Q: Can a waterproofing membrane be used on tunnels with electrical installations?

- Yes, a waterproofing membrane can be used on tunnels with electrical installations. The primary purpose of a waterproofing membrane is to prevent water infiltration and protect the underlying structures from moisture damage. In tunnels with electrical installations, it is crucial to ensure that the electrical equipment and wiring are protected from water damage to ensure the safe and efficient operation of the installations. By applying a waterproofing membrane to the tunnel walls and ceilings, any potential water ingress can be effectively prevented, reducing the risk of damage to the electrical installations. However, it is important to consult with professionals experienced in tunnel waterproofing to ensure that the chosen membrane is suitable for the specific requirements of the tunnel and electrical installations, considering factors such as fire resistance, electrical insulation, and durability.

- Q: Can waterproofing membranes be used on shower walls?

- Yes, waterproofing membranes can indeed be used on shower walls. In fact, they are an essential component of shower construction to prevent water leakage and potential damage to surrounding areas. Waterproofing membranes create a barrier that prevents water from seeping through the walls and into the structural components of the shower. They are typically installed behind the tile or other wall covering materials to provide an extra layer of protection. Waterproofing membranes are designed to be flexible, durable, and resistant to moisture, ensuring that the shower walls remain watertight and free from any potential water damage.

- Q: Can a waterproofing membrane be used for stadiums and sports arenas?

- Yes, a waterproofing membrane can be used for stadiums and sports arenas. It is a commonly used solution to protect these structures from water damage and leakage. The membrane helps in preventing water penetration and effectively keeps the interior areas dry and safe.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures or tears. It is typically made from durable materials such as PVC, TPO, or EPDM, which are known for their strength and resistance to damage. These membranes undergo rigorous testing to ensure their ability to withstand various environmental conditions and potential sources of punctures or tears, such as sharp objects or heavy foot traffic. Additionally, some waterproofing membranes come with reinforcement layers or added protection to further enhance their puncture and tear resistance. However, it is important to note that while waterproofing membranes are highly resilient, they are not completely impervious to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help maximize its longevity and performance.

- Q: Can a waterproofing membrane reduce noise transmission?

- Yes, a waterproofing membrane can reduce noise transmission.

Send your message to us

EPDM Waterproof Membrane Made from DUPONT Rubber

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords