EPDM Swimming Waterproof EPDM Pond Liner

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM waterproofing membrane

1. Brief Introduction:

It is a kind of self-adhesive waterproof coiled material based on polymer rubber and superior asphalt, together with polyethylene film and aluminum foil as surface material or no film(Double-sided self-adhesive). And it adopts the package preventing-adhesion-isolation-layer package, and dividing into no fiber and polyester fiber two parts.The coiled material has perfect performances, simple operation, non-pollution and etc.

2. Characters:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

3. Application:

1),Roofs, Basement, Toilet

2),Industrial and civil building waterproofing

3),Geosynthetic liner for swimming pool, channels, irrigation system

4),Especially suit for projects with high requirements in durability, anti-corrosion anddeformation

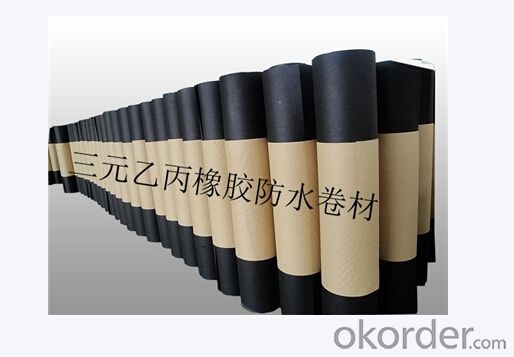

4. Package and Storage:

Each Roll with one plastic bag with or without pallets.

Keep in dry and ventilated place. Avoid shining and raining. Height of stack not more than 5 layers. Shelf life:12 months.

5. Specification:

Type | EPDM Waterproof Rubber Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

6. Installations:

1. adhere the EPDM membrane directly to the smooth and clean substrate like concrete deck, insulation board, etc.

2. Adjust membrane to make sure the overlaps is no less than 10cm and wiped clean.

3. Then, apply special adhesive evenly to both the substrate and the membrane laps or seam tape.

4. After minutes, press it securely and finish with sealant.

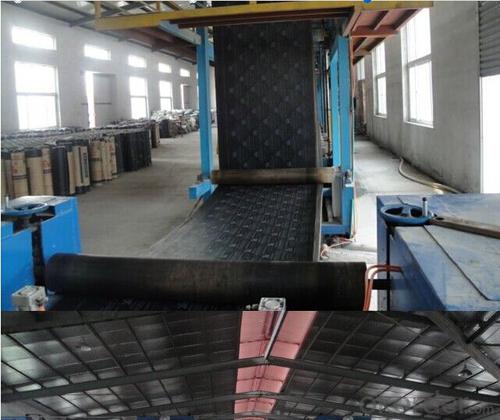

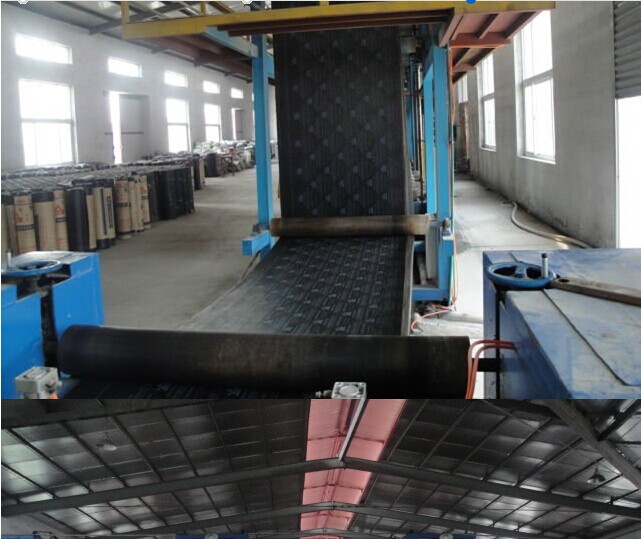

5. Some photos:

- Q: Are waterproofing membranes resistant to chlorine exposure?

- The resistance of waterproofing membranes to chlorine exposure can vary. Certain membranes are designed to withstand chlorine and are commonly used in areas like pool decks or water treatment facilities where chlorine exposure is expected. These membranes are typically made with materials like PVC or TPO that naturally resist chlorine and can endure prolonged exposure without significant damage. It is important to be aware that not all waterproofing membranes are resistant to chlorine. Some membranes, particularly those made with materials like EPDM or bitumen, may not hold up as well against chlorine and may deteriorate or sustain damage with extended exposure. To ensure a waterproofing membrane lasts and performs well in a chlorine-rich environment, it is vital to choose a membrane specifically designed and tested for chlorine resistance. Seeking guidance from a waterproofing professional or manufacturer can assist in determining the most suitable membrane for the particular chlorine exposure conditions.

- Q: Can a waterproofing membrane be used on precast plastic surfaces?

- Yes, a waterproofing membrane can be used on precast plastic surfaces. Waterproofing membranes are designed to create a barrier against moisture and can be applied to a variety of surfaces, including concrete, metal, and plastic. When properly installed, a waterproofing membrane can provide protection against water infiltration, ensuring the longevity and durability of the precast plastic surface. It is important to choose a waterproofing membrane that is compatible with plastic and follow the manufacturer's instructions for application to ensure proper adhesion and effectiveness.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Yes, a waterproofing membrane can be used for water treatment plants. Waterproofing membranes are designed to prevent the passage of water and can be used to provide a barrier against water leakage in various structures, including water treatment plants. These membranes can be applied to different areas of the plant, such as tanks, reservoirs, pipes, and basements, to prevent water infiltration and protect the infrastructure from potential damage. Additionally, waterproofing membranes can help maintain the integrity of the water treatment process by ensuring that water remains contained within designated areas and does not seep into surrounding soil or structures.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Yes, a waterproofing membrane can be used on tunnels with emergency exits. In fact, it is highly recommended to use a waterproofing membrane in such tunnels to prevent water infiltration and protect the structural integrity of the exits. Waterproofing membranes are designed to create a barrier against water and moisture, ensuring that the tunnels remain dry and free from water damage. This is especially important for emergency exits, as they need to be accessible and functional at all times. By installing a waterproofing membrane, the tunnels can be effectively protected from potential water ingress, ensuring the safety and usability of the emergency exits.

- Q: Can a waterproofing membrane be used in elevator pits?

- Yes, a waterproofing membrane can be used in elevator pits. Elevator pits are prone to water intrusion, as they are located underground and can be exposed to groundwater or other sources of moisture. A waterproofing membrane is a protective layer that is applied to the walls and floor of the elevator pit to prevent water from seeping through. It acts as a barrier and prevents water damage to the structural components of the elevator system, such as the electrical equipment, pumps, and hydraulic systems. By using a waterproofing membrane in elevator pits, the risk of water damage and corrosion can be significantly reduced, ensuring the safe and efficient operation of the elevator.

- Q: Can a waterproofing membrane be used for elevator pits and machine rooms?

- Yes, a waterproofing membrane can be used for elevator pits and machine rooms. Elevator pits and machine rooms are susceptible to water infiltration due to their location or proximity to underground water sources. This can lead to potential damage to the elevator machinery and electrical systems. To prevent water damage and ensure the longevity of the elevator system, it is crucial to apply a waterproofing membrane to these areas. A waterproofing membrane is a protective layer that is applied to the surface of a structure to prevent water penetration. It acts as a barrier against water and helps to keep the area dry and moisture-free. Waterproofing membranes are typically made of various materials such as bitumen, rubberized asphalt, or liquid-applied coatings. When applied to elevator pits and machine rooms, a waterproofing membrane provides an effective solution to prevent water seepage. It can be installed on the walls, floors, and even the ceiling of these areas to create a watertight seal. The membrane is resistant to water pressure, ensuring that no water enters the elevator pit or machine room. Moreover, waterproofing membranes also protect the elevator machinery and electrical systems from potential damage caused by water exposure. These systems are sensitive to moisture and can malfunction or corrode if exposed to water. By using a waterproofing membrane, the risk of such damage is significantly reduced, leading to improved reliability and longevity of the elevator system. In conclusion, a waterproofing membrane is a suitable solution for elevator pits and machine rooms as it effectively prevents water infiltration, protects the elevator machinery and electrical systems, and ensures the overall functionality and durability of the elevator system.

- Q: What should the attention of the membrane waterproof construction?

- (1) grass-roots coating on the base layer of treatment agent, requiring thin and uniform, generally dry, when the sticky hand can be paving the membrane;

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Yes, a waterproofing membrane typically requires specific cleaning methods. It is important to avoid using abrasive cleaners or tools that may damage the membrane. Instead, gentle cleaning solutions and soft brushes or cloths should be used to remove dirt and debris without compromising the membrane's integrity. Regular maintenance and cleaning will help prolong the lifespan and effectiveness of the waterproofing membrane.

- Q: Are waterproofing membranes resistant to freeze-thaw cycles?

- Yes, waterproofing membranes are generally resistant to freeze-thaw cycles. These membranes are designed to withstand extreme weather conditions, including freezing temperatures and the subsequent thawing process. The materials used in waterproofing membranes are often chosen for their durability and ability to expand and contract without compromising their waterproofing properties. This resistance to freeze-thaw cycles ensures that the membranes remain intact and effective in preventing water penetration, even in areas where temperature fluctuations occur frequently.

- Q: Is a waterproofing membrane suitable for below-grade applications?

- A waterproofing membrane is a suitable choice for below-grade applications, where the areas are situated beneath ground level, like basements or foundations. These regions are susceptible to water infiltration and moisture problems, which can result in harm and structural issues. The purpose of a waterproofing membrane is to prevent water from entering and act as a barrier against moisture. It can be applied either on the exterior or interior surface of the below-grade structure, creating a continuous and long-lasting seal. This membrane effectively prevents water from seeping into the below-grade area, ensuring a dry and stable environment. It is crucial to utilize a waterproofing membrane in below-grade applications to safeguard the structure against water damage, the growth of mold, and other associated concerns.

Send your message to us

EPDM Swimming Waterproof EPDM Pond Liner

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords