Black EPDM Pond Liner Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

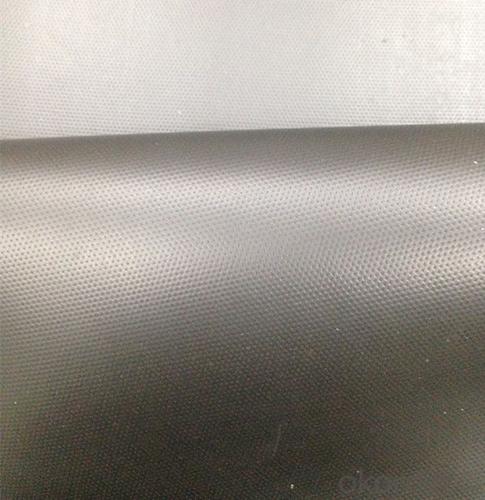

Product Instruction:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

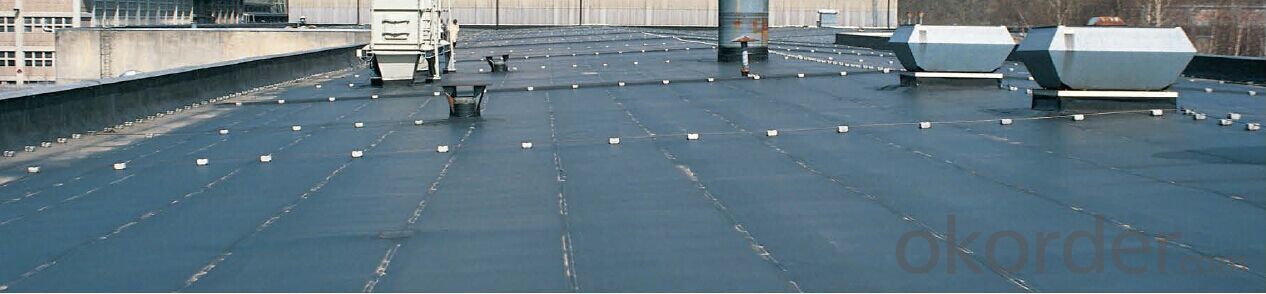

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos:

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Special considerations must be taken into account when installing a waterproofing membrane in seismic zones due to the risk of earthquakes and ground movements. To withstand the potential movements and vibrations caused by seismic activities, it is crucial to ensure that the membrane is capable of withstanding stress and strain. When installing a waterproofing membrane in seismic zones, several factors should be considered: 1. Flexibility: The membrane should possess sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or compromising its waterproofing properties. 2. Compatibility: It is important to select a waterproofing membrane that is compatible with the building materials and systems used in seismic zones. This ensures that the membrane bonds well with the substrate and other construction components, creating a seamless and robust waterproofing system. 3. Reinforcement: In areas with high seismic activity, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be achieved by incorporating a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should adhere to specific guidelines and techniques to ensure its effectiveness. This may involve using specific adhesives, primers, or mechanical fastening systems to securely install the membrane. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This allows for the identification of any potential issues or deficiencies in the waterproofing system, enabling prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can effectively safeguard the building structure against water intrusion and potential damage caused by earthquakes. Consultation with experienced professionals and adherence to industry standards and guidelines are imperative for a successful installation in these challenging environments.

- Q: Can a waterproofing membrane be used on precast galvanized surfaces?

- Yes, a waterproofing membrane can be used on precast galvanized surfaces. The waterproofing membrane is designed to provide a protective barrier against water penetration, and it can be applied to various surfaces including precast galvanized surfaces. The membrane helps to prevent water from seeping into the surface, protecting the underlying structure from moisture damage. However, it is important to ensure that the precast galvanized surface is properly prepared before applying the membrane, as any loose or flaking galvanized coating should be removed to ensure proper adhesion of the membrane. Additionally, it is advisable to consult with the manufacturer or supplier of the waterproofing membrane to ensure that it is compatible with galvanized surfaces and to follow their recommended application guidelines for best results.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is typically resistant to hydrocarbons or oil spills. Waterproofing membranes are designed to create a barrier that prevents water penetration and moisture damage to the underlying surfaces. These membranes are often made from materials such as modified bitumen, polyurethane, or PVC, which have excellent resistance to various chemicals, including hydrocarbons and oil. This resistance ensures that the membrane remains intact and effective even when exposed to oil spills or hydrocarbon-based substances. However, it is essential to note that the specific resistance may vary depending on the type and quality of the waterproofing membrane used. Therefore, it is crucial to select a membrane that is specifically engineered to withstand the intended environment and potential chemical exposures.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can a waterproofing membrane be used for a basement?

- Basements can indeed benefit from the use of a waterproofing membrane. It is highly recommended to employ this method in order to avoid water infiltration and the accumulation of moisture. A waterproofing membrane consists of a thin layer of material that is applied to the walls and floor of the basement, serving as a barrier against water. This layer acts as a protective shield, preventing water from penetrating the walls and causing harm to the foundation and interior of the basement. Furthermore, the use of a waterproofing membrane can also decrease the likelihood of mold and mildew growth, as it maintains a dry and moisture-free environment in the basement. In conclusion, the utilization of a waterproofing membrane is an effective remedy for ensuring waterproof basements and providing a safe and dry living space.

- Q: How does a waterproofing membrane handle cracks in the substrate?

- A waterproofing membrane is designed to handle cracks in the substrate by providing a barrier that prevents water from penetrating through the cracks. The membrane is typically made of a flexible material, such as rubber or synthetic polymers, which allows it to stretch and move with the substrate without tearing or breaking. When cracks occur in the substrate, the membrane is able to bridge over the cracks and maintain its integrity, preventing water from seeping through. In some cases, the membrane may have a self-healing property, where it can seal minor cracks on its own, ensuring continuous protection against water ingress. To further enhance its crack-bridging capability, the waterproofing membrane may be reinforced with fibers or fabric layers. These reinforcements increase the tensile strength and flexibility of the membrane, allowing it to effectively span larger cracks or accommodate movement in the substrate without compromising its waterproofing performance. It is important to note that the extent to which a waterproofing membrane can handle cracks in the substrate depends on various factors, such as the type and size of the cracks, the movement of the substrate, and the quality of the membrane installation. It is essential to follow the manufacturer's guidelines and ensure proper surface preparation and installation techniques to maximize the membrane's ability to handle cracks and provide long-lasting waterproofing protection.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Yes, a waterproofing membrane typically requires specific preparation of the substrate before installation. The substrate needs to be clean, dry, and free from any debris, oils, or contaminants that may hinder adhesion. It may also require smoothing or leveling of the surface to ensure proper application and effectiveness of the membrane.

- Q: Can a waterproofing membrane be used for swimming pool decks?

- Yes, a waterproofing membrane can be used for swimming pool decks. A waterproofing membrane is a protective barrier that prevents water from seeping into the underlying structure. It is commonly used in areas where water exposure is high, such as swimming pool decks, to ensure the longevity and durability of the structure. The membrane is typically applied over the concrete surface of the pool deck and provides a seamless, watertight seal. This helps to prevent water damage, such as cracking, spalling, or deterioration of the concrete, and minimizes the risk of leaks or water seepage into the surrounding areas. Additionally, a waterproofing membrane can also provide added benefits such as slip resistance, UV resistance, and protection against chemicals and stains. It is important to choose a high-quality waterproofing membrane that is specifically designed for swimming pool decks and can withstand frequent exposure to water and other environmental factors.

- Q: Can a waterproofing membrane be used for a warehouse?

- Yes, a waterproofing membrane can be used for a warehouse. A waterproofing membrane is designed to protect surfaces from water penetration, making it a suitable solution for warehouses that require protection against moisture, leaks, and potential water damage.

- Q: Is a waterproofing membrane resistant to mold and mildew growth?

- Yes, a waterproofing membrane is typically resistant to mold and mildew growth. The membrane acts as a barrier against moisture, preventing it from seeping into the building materials and creating an environment for mold and mildew to thrive.

Send your message to us

Black EPDM Pond Liner Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords