EPDM Waterproof Membrane with Weldable for Pond Liner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane with Weldable for Pond Liner

Description Of EPDM Waterproof Membrane with Weldable for Pond Liner:

1. Excellent physical and mechanical performance, high tearing resistance;good deformation adaptability, high puncture resistance;

2. High aging resistance, high UV resistance, anti-acid & alkali;

3. Excellent low & high temperature resistance, innocuous, long life span;

4. Perfect water proof performance, seepage and humidity resistance.

Main Features of EPDM Waterproof Membrane with Weldable for Pond Liner:

A.Polyester based SBS Modified Bitumen Waterproofing Membrane

a. Strong impermeability

b. High tensile strength, elongation, ability to adapt the grassroots shrinkage deformation and cracking

c. Puncture-resistant, broken resistant, tear-resistant

d. The corrosion resistance, resistance to mildew, weathering good

e. Construction convenient, hot-melt can be operated Four Seasons Construction, reliable joints

B. Fiberglass based SBS Modified Bitumen Waterproofing Membrane

a. High tensile strength, stability of a good size

b. High Temperature good performance

c. Damage resistance, corrosion resistance, resistance to mildew, weathering good performance

d. Good construction performance, reliable joints.

Specifications of EPDM Waterproof Membrane with Weldable for Pond Liner:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Waterproof Membrane with Weldable for Pond Liner:

geomembrane used in groundsill of road, highway, railway and waterproof layer of swelling clay and wet collapsed loess.Geomembrane can be widely used in areas of garbage burying, waste disposal and underground construction projects.such as below:

- aquaculture ponds

- Ouchi root barrier membrane

- Floating baffles;

- Process wastewater

- Stormwater impoundments;

- Secondary containment;

- Spill containment

- Manure and biogas tanks and covers

- Potable water tanks and covers;

- Sludge Drying beds;

- Bioremediation covers & liners;

- Leachate ponds

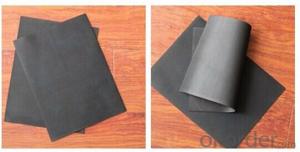

IMages of EPDM Waterproof Membrane with Weldable for Pond Liner:

FAQ of EPDM Waterproof Membrane with Weldable for Pond Liner:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for solar panel installations?

- Yes, a waterproofing membrane can be used for solar panel installations. In fact, it is often recommended to use a waterproofing membrane as part of the installation process to protect the roof or other surfaces beneath the solar panels from water damage. A waterproofing membrane acts as a barrier to prevent water from seeping into the underlying structure, ensuring that the solar panel installation remains watertight and secure. This is particularly important as solar panels are typically installed on rooftops, where they are exposed to various weather conditions. By incorporating a waterproofing membrane, it helps to prolong the lifespan of the solar panels and prevents any potential water-related issues that could affect their performance.

- Q: Can a waterproofing membrane be used for walkways or pedestrian bridges?

- Yes, a waterproofing membrane can be used for walkways or pedestrian bridges. Waterproofing membranes are designed to create a barrier that prevents water from seeping into the structure and causing damage. By applying a waterproofing membrane to the surface of a walkway or pedestrian bridge, it can protect the underlying structure from water infiltration, thus increasing its durability and lifespan. This is especially important in areas prone to heavy rainfall or where the walkway or bridge is exposed to water sources such as rivers or lakes. Additionally, waterproofing membranes can also provide additional benefits such as improving slip resistance and protecting against chemicals or pollutants.

- Q: Can a waterproofing membrane be used for loading docks or ramps?

- Certainly! A waterproofing membrane proves useful for loading docks and ramps. Its purpose lies in safeguarding surfaces against water damage by forming a barrier that halts the intrusion of water. As loading docks and ramps remain exposed to diverse weather conditions, they often fall victim to water seepage, leading to gradual harm. By applying a waterproofing membrane to these areas, one can avert water infiltration, thus shielding the structure and extending its lifespan. Furthermore, this membrane offers supplementary advantages like enhanced slip resistance, defense against chemical spills, and decreased maintenance expenses.

- Q: Can waterproofing membranes be used on concrete dams?

- Yes, waterproofing membranes can be used on concrete dams. These membranes are designed to provide a protective barrier against water penetration, helping to prevent leaks and ensure the structural integrity of the dam. By applying the waterproofing membrane to the concrete surface, it can effectively seal the pores and cracks, making the dam more resistant to water damage.

- Q: Can a waterproofing membrane be used for medical facilities?

- Yes, a waterproofing membrane can be used for medical facilities. Waterproofing membranes are commonly used in construction to prevent water ingress and protect buildings from moisture damage. In medical facilities, where cleanliness and hygiene are crucial, waterproofing membranes can be used to create a moisture barrier, preventing water and moisture from seeping into walls and floors, which can lead to mold growth or damage to sensitive medical equipment. Additionally, waterproofing membranes can aid in maintaining a sterile environment by preventing the growth of bacteria or other pathogens that could be present in damp conditions.

- Q: Are waterproofing membranes resistant to gasoline?

- Waterproofing membranes, in general, display resistance towards gasoline. These membranes are chemically resistant and capable of enduring exposure to diverse chemicals, which includes gasoline. Nevertheless, it is crucial to acknowledge that the extent of resistance may differ depending on the particular membrane type and its composition. Certain membranes may provide superior resistance to gasoline compared to others. Furthermore, extended exposure to gasoline can potentially harm or deteriorate the membrane over time, hence it is always advised to take essential precautions and avoid prolonged contact with harsh chemicals.

- Q: Can a waterproofing membrane be used in conjunction with other waterproofing methods?

- Yes, a waterproofing membrane can be used in conjunction with other waterproofing methods. In fact, combining multiple waterproofing methods can provide enhanced protection against water damage and ensure a more reliable and long-lasting waterproofing solution. The membrane can act as an additional layer of defense, complementing other methods such as sealing, drainage systems, or coatings, to provide a comprehensive waterproofing system.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Yes, a waterproofing membrane typically requires specific cleaning methods. It is important to avoid using abrasive cleaners or tools that may damage the membrane. Instead, gentle cleaning solutions and soft brushes or cloths should be used to remove dirt and debris without compromising the membrane's integrity. Regular maintenance and cleaning will help prolong the lifespan and effectiveness of the waterproofing membrane.

- Q: What is the accounting subject of the waterproofing membrane

- following two subjects repair costs. For the use of materials used in construction, included in the construction in progress

- Q: Can a waterproofing membrane be used for basements and crawl spaces?

- Yes, a waterproofing membrane can be used for basements and crawl spaces. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and moisture issues. A waterproofing membrane is a thin layer of material that is applied to the walls and floors of a basement or crawl space to create a barrier against water and moisture. This helps to keep the area dry and prevent water from seeping into the space, which can cause structural damage, mold growth, and other problems. Waterproofing membranes are designed to be durable and long-lasting, providing a reliable solution for protecting basements and crawl spaces from water intrusion.

Send your message to us

EPDM Waterproof Membrane with Weldable for Pond Liner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords