Waterproofing EPDM Pond Liner for Garden/Lake/Pond Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

2. Product Specification:

There are two installation ways.one is full sticking,the other is hot welding.

Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

Width | 1m to 4m |

Length | 20m |

Model | EPDM, EPDM with fabric |

3. Technical Sheet:

Number | Item | Unit | Value | |

1 | Size Variation | Thichness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

3 | Breaking elongation at normal temperature | % | ≥450 | |

Breaking elongation at -20°C | % | ≥200 | ||

4 | Tear strength | KN/m | ≥25 | |

5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

6 | Bending at low tempreture | °C | ≤-40 | |

7 | Stretch tensor at heating | Elongate | mm | ≤2 |

Shrink | mm | ≤4 | ||

8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥80 | ||

10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

4. Features:

1. Waterproofing EPDM pond liner has excellent resistance to environmental stress cracking resistance, aging resistance, corrosion resistance as well as long service life.

2.Waterproofing EPDM pond liner has the lowest permeability

3. Waterproofing EPDM pond liner has high elongation,heat treatment the size change is small

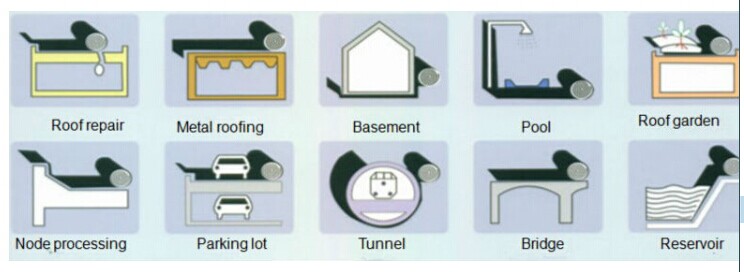

5. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

5. Some photos:

- Q: Can a waterproofing membrane be used in permanent or long-term structures?

- Certainly, permanent or long-term structures can indeed make use of a waterproofing membrane. By creating a protective barrier against water infiltration, waterproofing membranes are perfectly suited for structures requiring extended safeguarding against moisture, such as buildings, bridges, tunnels, and underground constructions. These membranes are typically crafted from resilient materials like modified bitumen, PVC, EPDM, or polyurethane, which boast exceptional resistance to water, UV rays, and other environmental elements. A properly installed waterproofing membrane can significantly prolong the lifespan of a structure by thwarting water damage, mold growth, and structural decay. It is therefore highly advisable to utilize a waterproofing membrane in permanent or long-term structures to ensure their robustness and longevity.

- Q: Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. These membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. They are made from materials like rubber, polyethylene, or PVC, which are inherently resistant to the corrosive effects of saltwater. This resistance allows waterproofing membranes to effectively protect structures and surfaces from water damage, even in saltwater environments. However, it is essential to choose a waterproofing membrane specifically designed for saltwater applications to ensure optimal performance and longevity.

- Q: Can a waterproofing membrane be used for hotels or resorts?

- Certainly, hotels or resorts can utilize waterproofing membranes. These membranes are widely employed in the construction sector to safeguard different structures against water damage, which includes hotels and resorts. Their objective is to create a barrier that hinders water infiltration, effectively averting leakages and moisture-related concerns. To ensure lasting protection, these membranes can be expertly applied to various areas within a hotel or resort, such as roofs, basements, bathrooms, swimming pools, and balconies. The implementation of a waterproofing membrane in these establishments is crucial to uphold structural integrity, forestall water damage, and offer guests a comfortable and secure environment.

- Q: How are waterproofing membranes installed?

- Waterproofing membranes are typically installed by first preparing the surface to ensure it is clean and free of any debris. Then, the membrane is unrolled and cut to size, ensuring it covers the entire area that needs to be waterproofed. Next, the membrane is adhered to the surface using a specialized adhesive or heat welding, depending on the type of membrane being used. Finally, any seams or joints are properly sealed to ensure a watertight installation.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- The resistance of waterproofing membranes to chlorine exposure can vary. Certain membranes are designed to withstand chlorine and are commonly used in areas like pool decks or water treatment facilities where chlorine exposure is expected. These membranes are typically made with materials like PVC or TPO that naturally resist chlorine and can endure prolonged exposure without significant damage. It is important to be aware that not all waterproofing membranes are resistant to chlorine. Some membranes, particularly those made with materials like EPDM or bitumen, may not hold up as well against chlorine and may deteriorate or sustain damage with extended exposure. To ensure a waterproofing membrane lasts and performs well in a chlorine-rich environment, it is vital to choose a membrane specifically designed and tested for chlorine resistance. Seeking guidance from a waterproofing professional or manufacturer can assist in determining the most suitable membrane for the particular chlorine exposure conditions.

- Q: What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can vary depending on various factors such as the quality of the membrane, the intensity and duration of the weather conditions, and the maintenance and care provided to the membrane. In general, high-quality waterproofing membranes designed for extreme weather conditions can have a lifespan of 20-30 years or more. These membranes are typically made from durable materials such as modified bitumen, PVC, EPDM, or TPO, which are specifically engineered to withstand harsh weather elements. However, it is important to note that extreme weather conditions, such as heavy rain, intense sunlight, freezing temperatures, or strong winds, can accelerate the wear and tear of the membrane. For example, prolonged exposure to UV radiation can cause the membrane to degrade and lose its effectiveness over time. Regular maintenance and inspections are crucial to prolonging the lifespan of the waterproofing membrane in extreme weather conditions. By promptly addressing any signs of damage, such as cracks, tears, or leaks, and conducting regular cleaning and resealing, the membrane can be better protected against the harsh effects of extreme weather. Furthermore, proper installation techniques and following manufacturer's guidelines are essential to ensure the longevity of the waterproofing membrane. Hiring experienced professionals who are familiar with installing membranes in extreme weather conditions can greatly contribute to the durability and lifespan of the membrane. Ultimately, while a high-quality waterproofing membrane can withstand extreme weather conditions for several decades, it is important to monitor its condition regularly, provide proper care and maintenance, and promptly address any issues that arise to maximize its lifespan.

- Q: Can a waterproofing membrane be used in industrial facilities or warehouses?

- In industrial facilities or warehouses, it is possible to utilize a waterproofing membrane. These types of facilities typically have concrete floors or walls that are prone to water damage caused by leaks or moisture. By applying a waterproofing membrane, it becomes possible to shield these areas from water penetration, thereby preventing any potential harm to the structure and its contents. The purpose of waterproofing membranes is to establish a barrier that effectively prevents water from seeping through the surface, making them a practical solution for industrial facilities and warehouses where moisture control is of utmost importance. Furthermore, these membranes possess durability and can endure heavy foot traffic and equipment, making them ideal for use in areas with high levels of activity. Ultimately, the utilization of a waterproofing membrane in industrial facilities or warehouses plays a crucial role in maintaining a dry and secure environment, ensuring the protection of the structure and its contents.

- Q: Can a waterproofing membrane be used on concrete block surfaces?

- Yes, a waterproofing membrane can be used on concrete block surfaces. It is commonly used to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Can a waterproofing membrane be used for a water tank liner?

- Indeed, a water tank liner can utilize a waterproofing membrane. The main purpose of waterproofing membranes is to obstruct water infiltration and can be employed on various surfaces, such as concrete, metal, and other commonly used materials in water tank construction. These membranes establish a barrier that thwarts leakage, cracks, and other types of water harm, thus guaranteeing the water tank's strength and durability. Moreover, waterproofing membranes are usually flexible, enabling them to adapt to the tank's shape and accommodate any potential movement or settlement. However, it is crucial to select a waterproofing membrane specifically engineered for water tank applications to ensure optimal performance and long-lastingness.

- Q: Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

Send your message to us

Waterproofing EPDM Pond Liner for Garden/Lake/Pond Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords