EPDM Waterproof Rubber Membrane for Pond Liner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Rubber Membrane for Pond Liner

Description Of EPDM Waterproof Rubber Membrane for Pond Liner:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Rubber Membrane for Pond Liner:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications of EPDM Waterproof Rubber Membrane for Pond Liner:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Rubber Membrane for Pond Liner:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

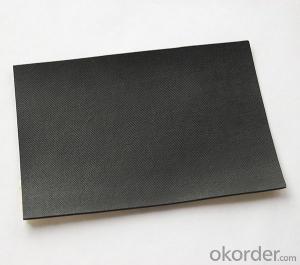

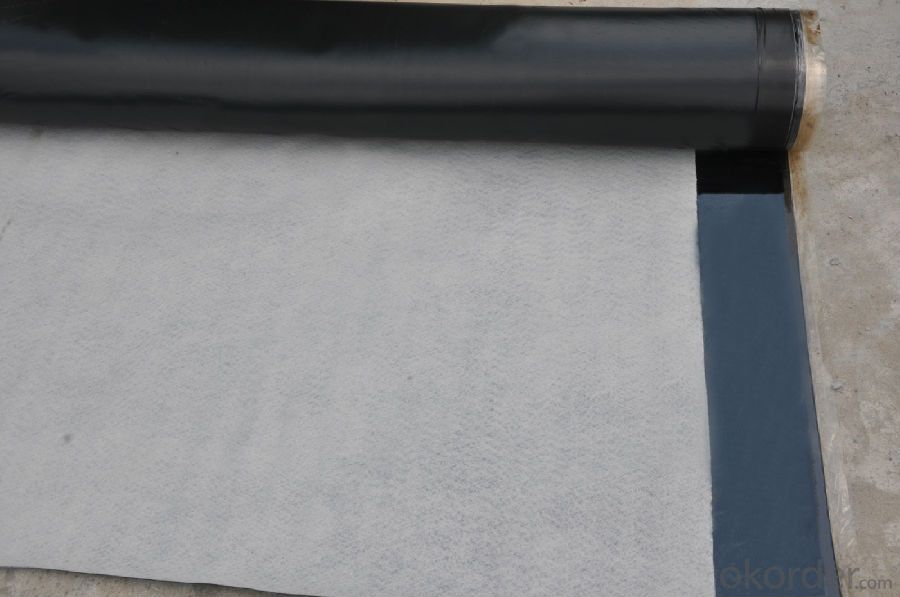

IMages of EPDM Waterproof Rubber Membrane for Pond Liner:

FAQ of EPDM Waterproof Rubber Membrane for Pond Liner:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, bridge decks and roadways can benefit from the use of a waterproofing membrane. This protective layer prevents water infiltration and increases the lifespan of the structure. Given the harsh weather conditions and heavy traffic that bridge decks and roadways face, a waterproofing membrane is essential. Water penetration can cause damage to bridge decks and roadways, including corrosion of steel reinforcements and deterioration of concrete. By applying a waterproofing membrane, a barrier is created to prevent water from seeping into the structural elements. This reduces the risk of corrosion and extends the durability of the bridge or roadway. Additionally, a waterproofing membrane can help prevent the formation of cracks and potholes, which are often caused by the freeze-thaw cycle and water penetration. By keeping the surface of the bridge deck or roadway dry, the membrane maintains its structural integrity and avoids costly repairs or premature replacement. It is important to consider factors such as material selection, installation techniques, and maintenance when using a waterproofing membrane in bridge decks or roadways. The chosen membrane should be compatible with the construction materials, and the installation process must be done correctly to ensure a watertight seal. Regular maintenance and inspections should also be done to identify any issues or damage to the membrane. This allows for timely repairs and ensures its effectiveness over time. Overall, using a waterproofing membrane in bridge decks or roadways is an efficient solution to protect against water damage and extend the lifespan of these critical infrastructure elements.

- Q: Are waterproofing membranes resistant to fire?

- No, waterproofing membranes are not inherently resistant to fire.

- Q: Can a waterproofing membrane be used in high-rise buildings?

- High-rise buildings can benefit from the use of a waterproofing membrane. Incorporating a waterproofing system is highly recommended to safeguard these structures from the harmful consequences of water infiltration. Waterproofing membranes serve as a protective barrier, effectively preventing leaks and moisture damage to the building. They are commonly applied on roofs, basements, foundations, and other areas exposed to water or moisture. The choice of the appropriate waterproofing membrane relies on several factors, including the building's specific design, construction materials, and environmental conditions. It is crucial to seek advice from experienced waterproofing professionals to identify the most suitable membrane system for long-term protection against water-related problems in high-rise buildings.

- Q: Can a waterproofing membrane be used on concrete tanks?

- Concrete tanks can indeed benefit from the use of a waterproofing membrane. The primary purpose of this membrane is to create a barrier that prevents water from penetrating through. It is specifically designed to be applied on various surfaces, including concrete. Waterproofing membranes are especially useful for concrete tanks that are used for water storage or containment. By applying the membrane on the concrete surface, a protective layer is formed that effectively stops water from entering or exiting the tank. This is crucial for maintaining the tank's structural integrity and avoiding any potential damage or contamination caused by water leakage. Furthermore, these membranes also offer protection against other substances that may be present in the tank, such as chemicals or pollutants. It is important to choose the right type of membrane that suits the specific requirements of the concrete tank. Following the manufacturer's instructions for application is also essential to ensure that the waterproofing is effective and long-lasting.

- Q: Can a waterproofing membrane be installed on metal surfaces?

- A waterproofing membrane is capable of being installed on metal surfaces, indeed. There exist various types of waterproofing membranes to choose from, with some specifically intended for metal substrates. These membranes are typically constructed using materials like PVC, TPO, or EPDM, which possess flexibility and a good adhesive quality to adhere well to metal surfaces. The installation process primarily involves cleaning and preparing the metal surface, and if required, applying a primer. Following this, the waterproofing membrane is applied using adhesive or heat welding techniques. This application creates a protective barrier against water infiltration, thereby preventing corrosion and damage to the metal surface. It is crucial to ensure that the chosen waterproofing membrane is compatible with the specific type of metal in use, and that proper installation procedures are followed to achieve effective waterproofing.

- Q: Can a waterproofing membrane be used on tunnels with soundproofing systems?

- Yes, a waterproofing membrane can be used on tunnels with soundproofing systems. Waterproofing membranes are designed to prevent the penetration of water into structures, while soundproofing systems are designed to minimize the transmission of sound. These two systems serve different purposes and can be used together in tunnels to ensure both water protection and sound insulation.

- Q: Can a waterproofing membrane be used on tunnels with water drainage systems?

- Yes, a waterproofing membrane can be used on tunnels with water drainage systems. A waterproofing membrane is designed to provide a protective barrier against water penetration and can effectively prevent water leakage into the tunnel. However, it is important to ensure that the waterproofing membrane is compatible with the specific water drainage system in place. The membrane should be installed in such a way that it does not obstruct or interfere with the functioning of the drainage system. Additionally, proper consideration should be given to the design and installation of the drainage system to ensure efficient water management and prevent any potential issues that could compromise the effectiveness of the waterproofing membrane. Overall, with proper planning and installation, a waterproofing membrane can be successfully used in tunnels with water drainage systems to ensure the overall integrity and longevity of the structure.

- Q: How does a waterproofing membrane perform in areas with heavy foot traffic?

- A waterproofing membrane is designed to provide a protective barrier against moisture and water penetration in various applications. When it comes to areas with heavy foot traffic, the performance of a waterproofing membrane is crucial. In such areas, the durability and strength of the membrane become essential factors. A high-quality waterproofing membrane that is specifically engineered for heavy foot traffic is capable of withstanding the constant stress and pressure exerted by people walking, running, or even using heavy equipment. One way a waterproofing membrane performs well in areas with heavy foot traffic is by maintaining its integrity and preventing any water or moisture from seeping through. It acts as a reliable shield, ensuring that the underlying structure remains dry and protected. This is particularly important in areas such as balconies, terraces, or concrete walkways, where water infiltration can lead to structural damage, corrosion, or mold growth. Additionally, a good waterproofing membrane for heavy foot traffic areas should possess excellent abrasion resistance. This means it can withstand the friction and wear caused by frequent foot traffic without deteriorating or losing its waterproofing properties. The membrane should be able to resist damage from shoes, heels, or other objects that may come into contact with its surface. Furthermore, a waterproofing membrane suitable for heavy foot traffic areas should be slip-resistant to ensure the safety of individuals walking on it. It should provide sufficient traction and grip, even when wet, to prevent accidents or injuries. This is especially crucial in spaces like swimming pool decks or commercial buildings where the risk of slipping is higher. In conclusion, a waterproofing membrane designed for heavy foot traffic areas performs by effectively sealing the surface, preventing water infiltration, and protecting the underlying structure. It should possess durability, strength, abrasion resistance, and slip resistance to ensure optimal performance and safety in areas subjected to heavy foot traffic.

- Q: Can waterproofing membranes be used on loading docks?

- Yes, waterproofing membranes can be used on loading docks. Waterproofing membranes are commonly used in various construction projects to prevent water infiltration and protect the underlying structure. Since loading docks are exposed to rain, snow, and other weather conditions, applying a waterproofing membrane can help to keep the dock area dry and prevent water damage.

- Q: Can a waterproofing membrane be used in temporary or temporary structures?

- Yes, a waterproofing membrane can be used in temporary or temporary structures. Waterproofing membranes are designed to provide a protective barrier against water penetration, which is essential in preventing moisture damage in any type of building structure. Whether it is a permanent or temporary structure, such as a temporary shelter, tent, or temporary construction site, a waterproofing membrane can be applied to ensure water resistance and protection. It is important to choose a waterproofing membrane that is suitable for the specific needs of the temporary structure and follow proper installation guidelines to ensure its effectiveness.

Send your message to us

EPDM Waterproof Rubber Membrane for Pond Liner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords